Oxygen-electricity combined calcium carbide smelting furnace and system

An oxygen-electricity combined and smelting furnace technology, applied in the direction of carbide, calcium carbide, etc., can solve the problems of difficulty in ensuring that the reaction is fully completed and the grade of calcium carbide is low, and achieve the effect of shortening the smelting time, fast smelting process, and promoting full completion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The embodiment of the present invention relates to an oxygen-electricity combined calcium carbide smelting method, comprising the following steps:

[0022] Step 1, preparing powdery carbon-based raw materials and powdery calcium-based raw materials, and drying the powdery carbon-based raw materials and powdery calcium-based raw materials. Wherein, in the process of preparing raw materials, the particle diameters of the powdered carbon-based raw materials and powdered calcium-based raw materials are controlled within the range of 0.07-1 mm, so that the carbon-based raw materials and calcium-based raw materials are in the form of fine powders with a high surface area. Activity, thereby enhancing the smelting rate of calcium carbide and reducing the reaction temperature. During the drying process, the weight percentage of the moisture in the powdered carbon-based raw material and the powdered calcium-based raw material is controlled below 0.3%, so that the carbon-based raw...

Embodiment 2

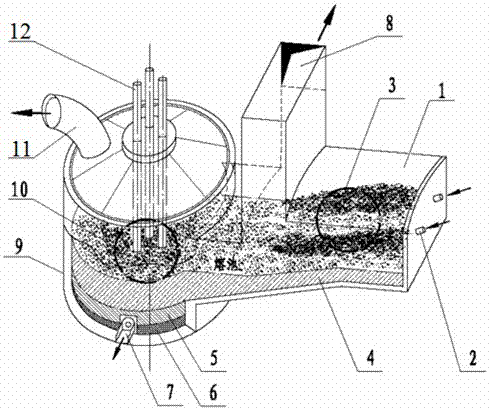

[0030] Such as figure 1 , the embodiment of the present invention relates to an oxygen-electricity combined calcium carbide smelting furnace 101, comprising a flash smelting furnace body 1, and a mixing nozzle 2 is arranged on the flash smelting furnace body 1, and the mixing nozzle 2 is connected with a powdery carbon-based Raw material supply mechanism, powdered calcium-based raw material supply mechanism and oxygen-containing gas delivery mechanism, powdery carbon-based raw material, powdered calcium-based raw material and oxygen-containing gas are sprayed into the flash smelting furnace body 1 through the mixing nozzle 2 The reaction forms an oxygen thermal reaction zone 3; the bottom of the flash smelting furnace body 1 has a molten pool in the reaction zone, and the molten pool in the reaction zone extends to one side of the flash smelting furnace body 1 to form a molten pool in the refining zone, and An electrode refining furnace body 9 is arranged above the melting poo...

Embodiment 3

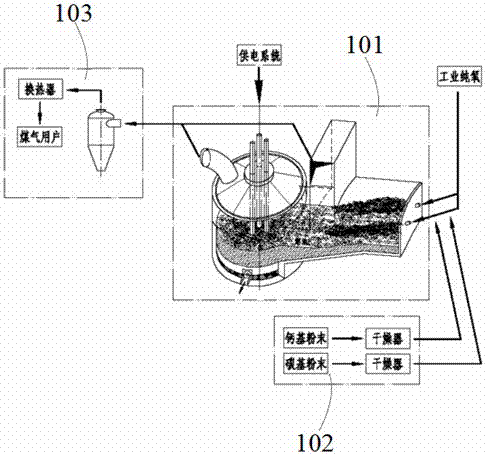

[0036] The embodiment of the present invention relates to an oxygen-electricity combined calcium carbide smelting system, including a calcium carbide smelting furnace 101. The calcium carbide smelting furnace 101 adopts the oxygen-electricity combined calcium carbide smelting furnace 101 provided in Embodiment 2, which will not be repeated here. The mixing nozzle 2 of the oxygen-electricity combined calcium carbide smelting furnace 101 is connected with a powdery raw material supply system 102 and an oxygen-containing gas delivery mechanism; the powdery raw material supply system 102 includes a powdery carbon-based raw material supply mechanism and a powdery calcium-based raw material supply mechanism, The powdery carbon-based raw material supply mechanism includes a carbon-based raw material pulverizing unit and a carbon-based raw material drying unit, and the powdered calcium-based raw material supply mechanism includes a calcium-based raw material pulverizing unit and a calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com