Preparing method for tetraammineplatinum(II) dichloride

A technology of dichlorotetraammine platinum and chloroplatinum, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc., which can solve the problem of unsuitable large-scale production and affecting product purity , Water pollution and other problems, to achieve the effect of environmental protection, product purity and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited to the stated scope.

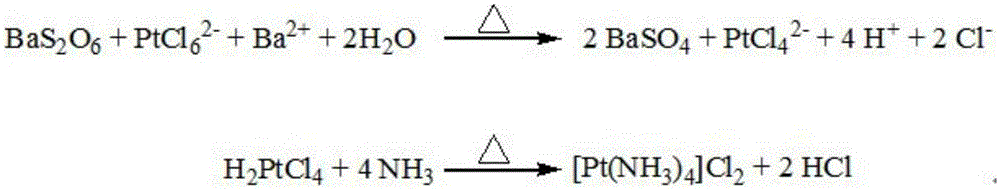

[0015] Such as figure 1 As shown, prepare tetrachloroplatinum (II) acid solution: weigh 5.18gH 2 PtCl 6 ·6H 2 O was added to a round bottom flask, 50g of water was added, stirred to dissolve it, and 1.97g of BaCO was added 3 After stirring evenly, add 20g containing BaS 2 o 6 2.97g of the solution, after reacting at 80°C for 24 hours, filtered off the precipitate to obtain tetrachloroplatinum (II) acid solution;

[0016] Prepare dichlorotetraammineplatinum solution: add 12 mL of 24% ammonia water to the above tetrachloroplatinum (II) acid solution, and reflux for 5 hours under normal pressure and boiling conditions until there is no green precipitate, and colorless dichloroplatinum is obtained. Platinum chloride solution;

[0017] Solvent crystallization: Concentrate the above solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com