Method for refining 2,6-diisopropylnaphthalene

A technology of diisopropylnaphthalene and refining method, which is applied in the field of refining 2,6-diisopropylnaphthalene, can solve problems such as difficult industrial application, low product purity, complicated process, etc., to improve reaction conversion rate and product The effect of yield, guaranteed product purity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

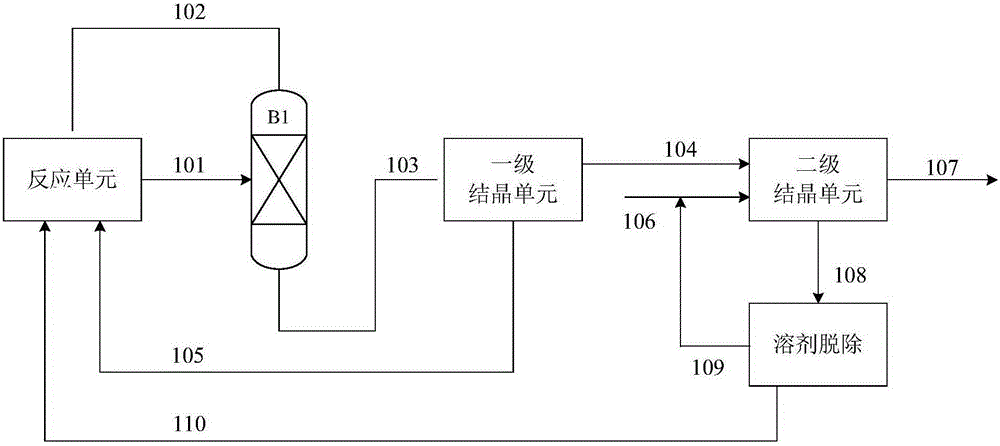

[0027] use figure 1 In the flow process shown, the stream (101) is the reaction product from the reaction unit, and its composition in weight percent is: 16.83% of naphthalene, 39.06% of monoisopropylnaphthalene, 15.34% of 2,6-diisopropylnaphthalene, 2,7-Diisopropylnaphthalene 23.58% and other light and heavy components 5.19%.

[0028] The number of theoretical plates of rectification column B1 is 30, the stream (101) enters from the 22nd theoretical plate, the operating pressure is 10KPa, the reflux ratio is 1.0, the temperature at the top of the tower is 155.95°C, and the temperature at the bottom of the tower is 221.61°C. After separation, the stream (103) does not contain naphthalene, and the composition of 2,6-diisopropylnaphthalene is 34.78% by weight; the stream (103) enters the primary suspension crystallization unit, the crystallization temperature is -15°C, and the crystallization time is 6hr. After suspended crystallization and filtration, the purity of 2,6-diisopr...

Embodiment 2

[0030] Adopt the same flow process and raw material composition as embodiment 1. The number of theoretical plates of rectification column B1 is 20, the stream (101) enters from the 12th theoretical plate, the operating pressure is 30KPa, the reflux ratio is 2.3, the temperature at the top of the tower is 192.64°C, and the temperature at the bottom of the tower is 261.36°C. The stream (103) does not contain naphthalene, and the composition of 2,6-diisopropylnaphthalene is 34.78% by weight; the stream (103) enters the primary suspension crystallization unit, the crystallization temperature is -20°C, and the crystallization time is 7hr , after suspended crystallization and filtration, the purity of 2,6-diisopropylnaphthalene in weight percent in the crystal of stream (104) is 73.13%; stream (104) continues to enter secondary solvent crystallization unit, solvent is methanol, The crystallization temperature is 0°C, and the crystallization time is 7hr. After solvent crystallization...

Embodiment 3

[0032] use figure 1 In the flow process shown, the stream (101) is the reaction product from the reaction unit, and its composition in weight percent is: naphthalene 8.67%, monoisopropylnaphthalene 20.47%, 2,6-diisopropylnaphthalene 26.17%, 2,7-Diisopropylnaphthalene 38.26% and other light and heavy components 6.43%.

[0033] The number of theoretical plates of the rectifying column B1 is 25, the stream (101) enters from the 17th theoretical plate, the operating pressure is 5KPa, the reflux ratio is 1.5, the temperature at the top of the tower is 136.20°C, and the temperature at the bottom of the tower is 199.48°C. The stream (103) does not contain naphthalene, and the composition of 2,6-diisopropylnaphthalene is 36.91% by weight; the stream (103) enters the primary suspension crystallization unit, the crystallization temperature is -9°C, and the crystallization time is 5hr , after suspended crystallization and filtration, the purity of 2,6-diisopropylnaphthalene in weight pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com