A production process of krypton and xenon gas and its production line

A production process and production line technology, applied in the production of bulk chemicals, inert gas compounds, specific gas purification/separation, etc., can solve the problems of low preparation purity and poor heat exchange effect, and achieve full reaction and improved full contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

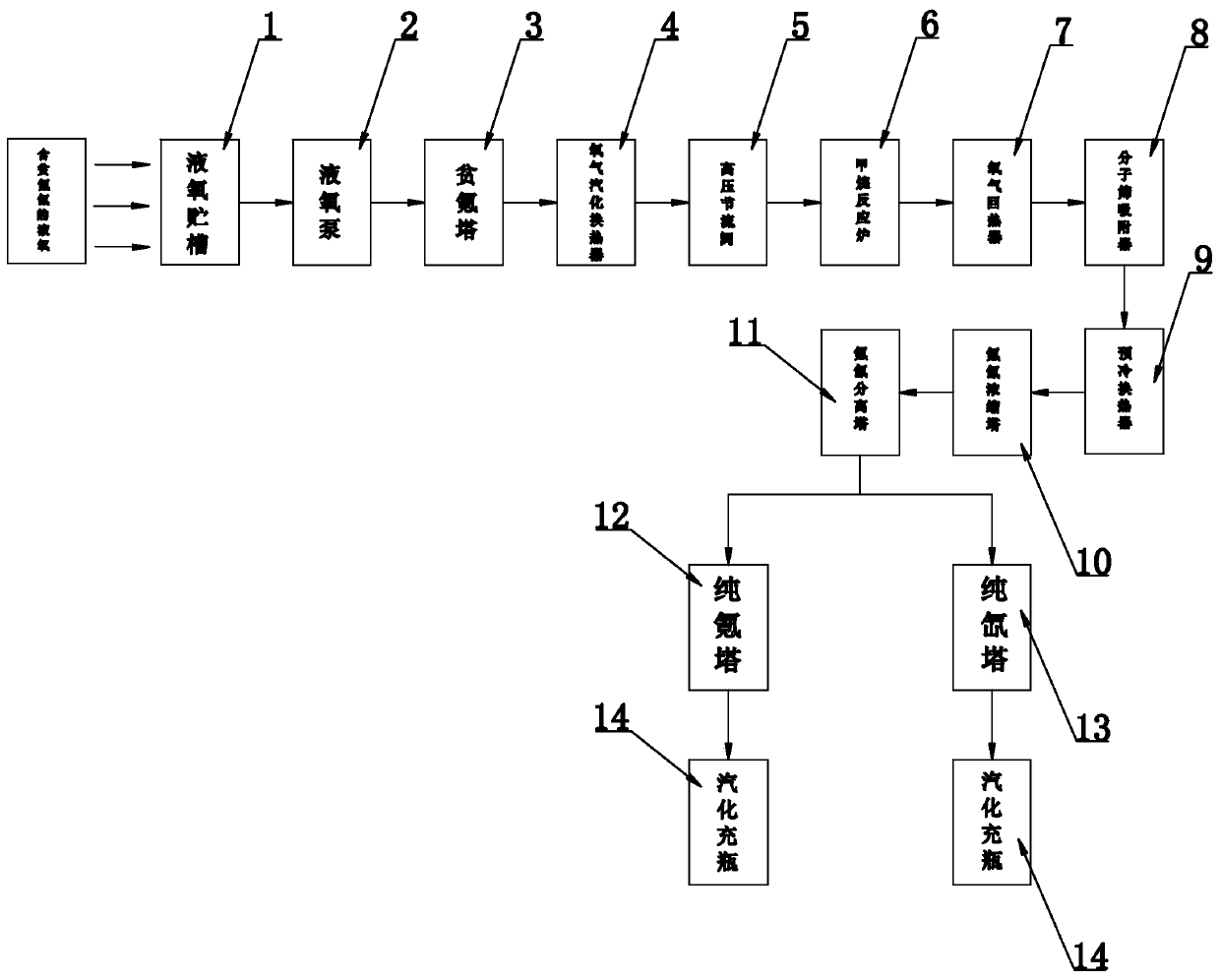

[0033] like figure 1 As shown, the present invention discloses a production process of krypton and xenon, which is characterized in that: comprising the following steps:

[0034] (1) Separating 1# and 2# air-separated liquid oxygen containing poor krypton and xenon into the liquid oxygen storage tank, entering the lean krypton tower through the liquid oxygen pump, initially concentrating in the lean krypton tower, pumping out and compressing to supercritical pressure;

[0035] (2) Send the initially concentrated liquid oxygen containing krypton and xenon to the oxygen vaporization heat exchanger for vaporization, and the temperature rises to normal temperature. The vaporized oxygen is throttled to 1.0MPa(A) through the high-pressure throttle valve, and then sent to the The oxygen regenerator exchanges heat with the high-temperature recirculating oxygen, and enters the electric heater for heating, and the temperature reaches 450°C;

[0036] (3) The heated liquid oxygen contain...

Embodiment 2

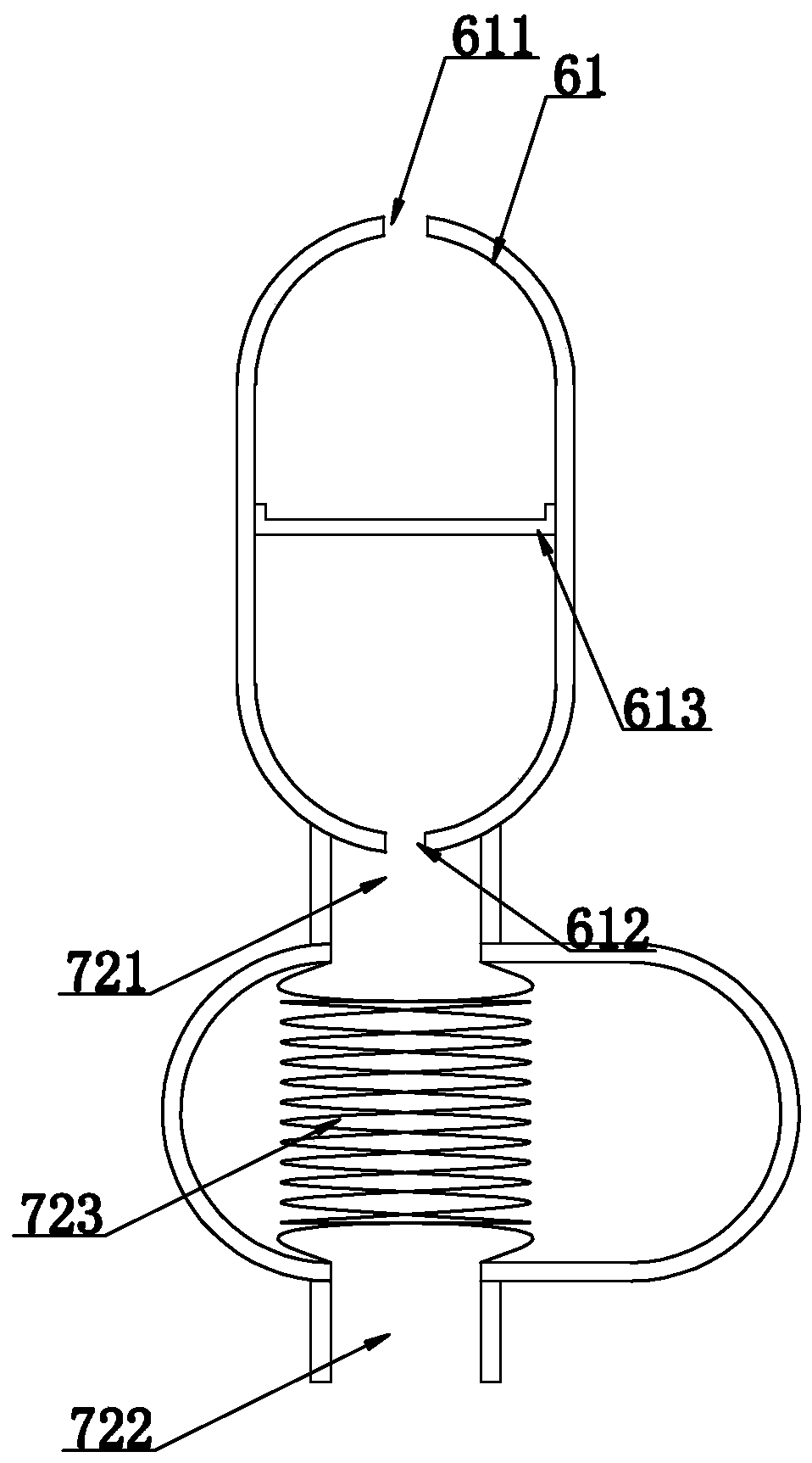

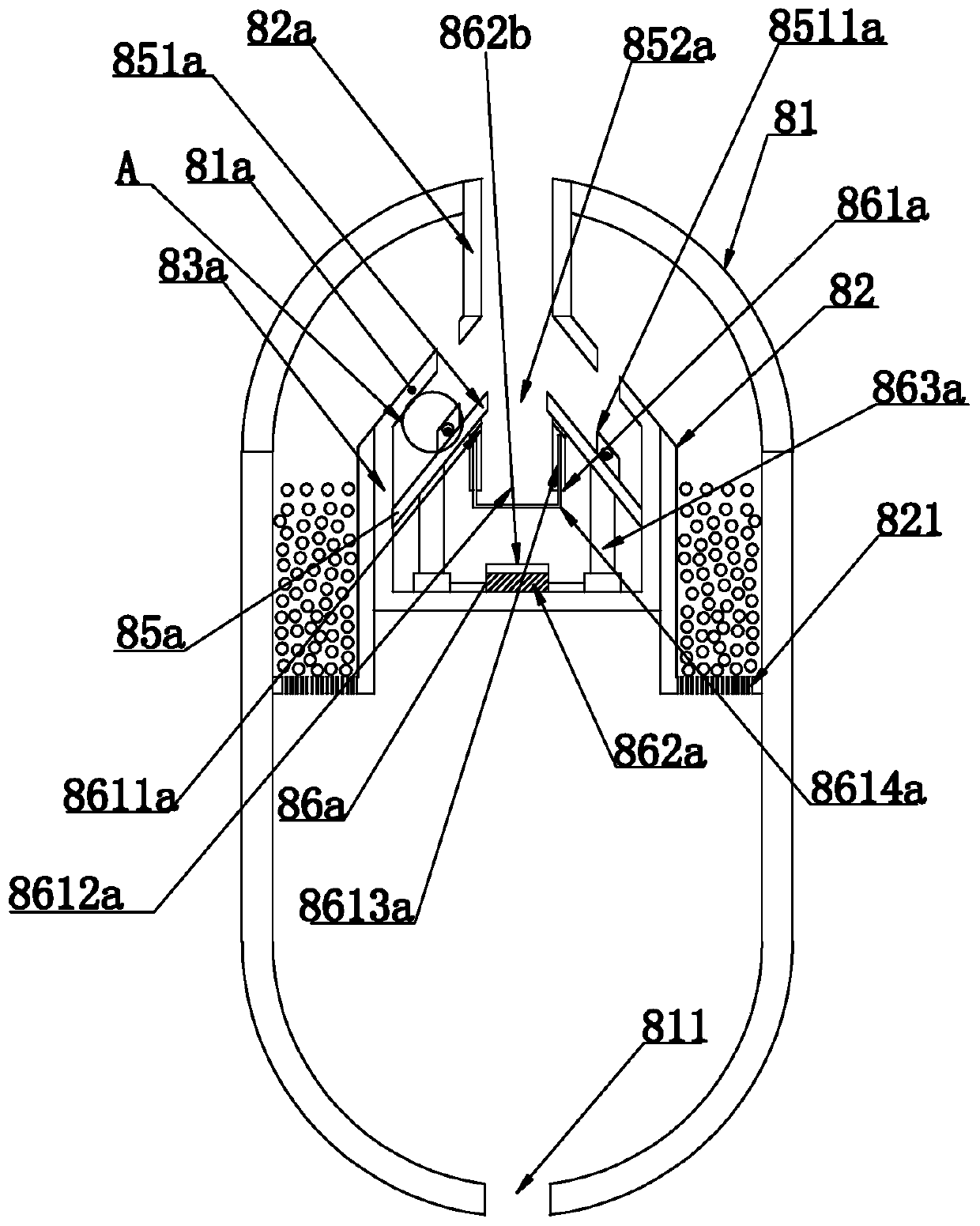

[0043] like Figure 2~Figure 6 As shown, the present invention discloses a production line for krypton and xenon gas production processes. In a specific embodiment of the present invention, it includes liquid oxygen storage tank 1, liquid oxygen pump 2, lean krypton tower 3, oxygen vaporization heat exchange device 4, high-pressure throttle valve 5, methane reaction furnace 6, oxygen regenerator 7, molecular sieve adsorber 8, precooling heat exchanger 9, krypton-xenon concentration tower 10 and krypton-xenon separation tower 11, the krypton-xenon separation tower 11 is respectively connected with pure xenon tower 13 and pure krypton tower 12, and pure xenon tower 13 and pure krypton tower 12 are all connected with vaporization filling bottle 14.

[0044] In a specific embodiment of the present invention, the methane reaction furnace 6 includes a furnace body 61, the upper part of the furnace body 61 is provided with a feed inlet 611, the lower part of the furnace body 61 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com