Sludge condensation dewatering treatment equipment

A technology for sludge concentration and treatment equipment, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of limited sludge concentration effect, large equipment investment, low work efficiency, etc., to improve dewatering efficiency and dewatering quality, Stable and reliable work, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

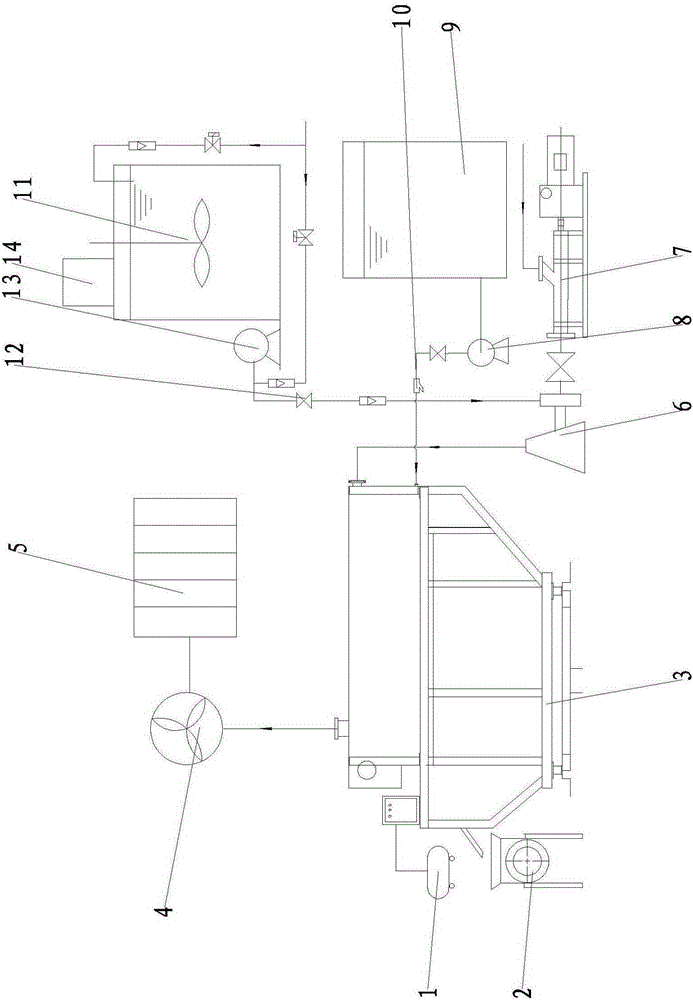

[0015] Such as figure 1 As shown, the present invention mainly includes a conveyor 2, a sludge thickening and dewatering machine 3, a deodorizing device 5, a mixer 6, a sludge pump 7, a flushing pump 8, a water tank 9, a dispensing box 11, a dosing pump 13 and a dry powder machine 14.

[0016] The feed port of the sludge thickening and dehydrating machine 3 is connected to the mixer 6 through a feed pipe, and the first feed end of the mixer 6 is connected to the discharge end of the sludge pump 7 . There is a conveyor 2 at the outlet of the sludge thickening and dehydrating machine 3, and the sludge enters the sludge thickening and dehydrating machine 3 after passing through the sludge pump 7 and the mixer 6 for dehydration treatment, and the treated sludge enters through the outlet In conveyor 2.

[0017] The second feed end of the mixer 6 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com