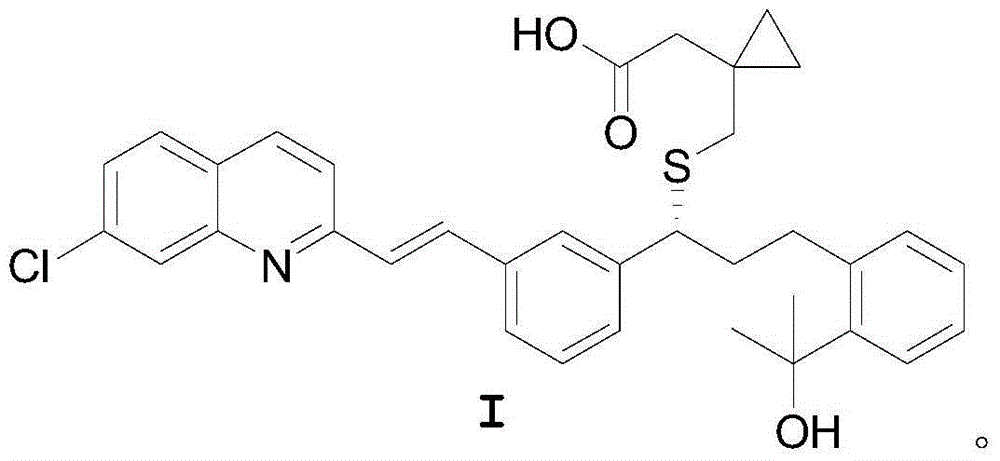

Method for preparing montelukast acid

A montelukast acid and reaction technology, applied in the direction of organic chemistry, etc., can solve the problems of difficult operation, troublesome post-processing, small implementation, etc., and achieve the effects of cheap and easy-to-obtain raw materials and simple reaction operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

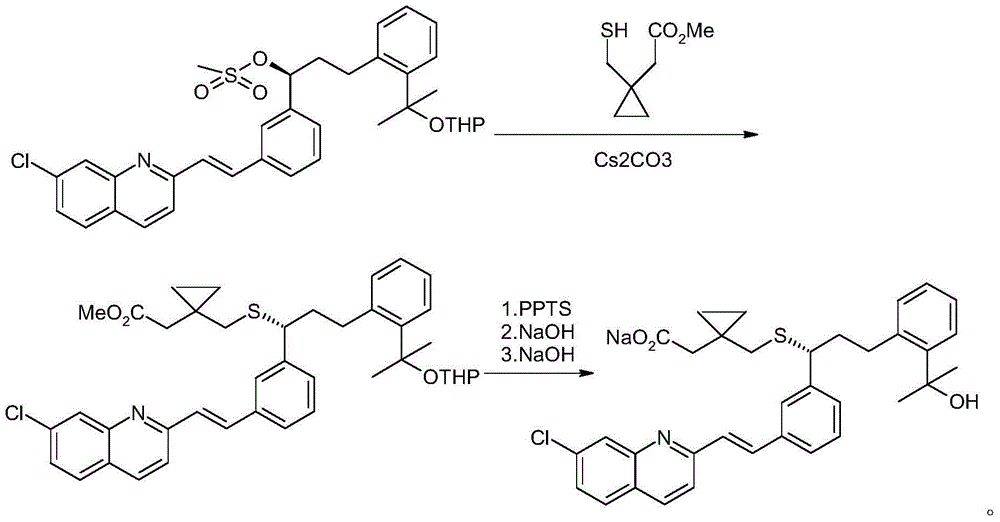

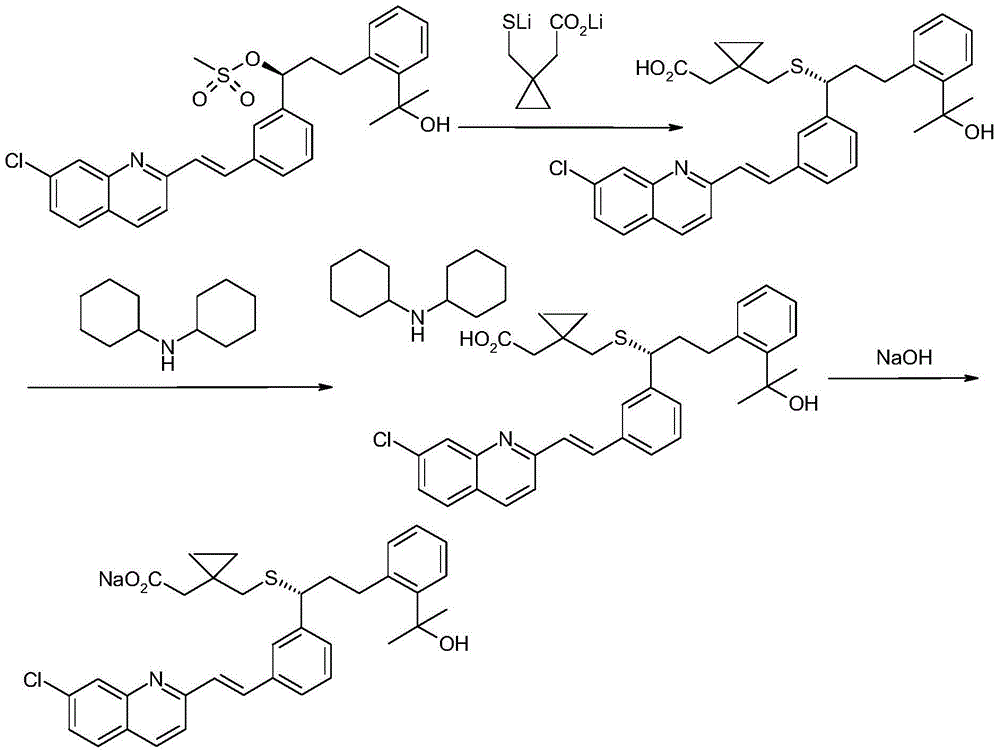

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the preparation of formula III compound

[0036]

[0037] The compound of formula IV (50g, 0.11mol) was dissolved in 200mL of dichloromethane, triethylamine (13.1g, 0.13mol) was added, diphenoxyphosphoryl chloride (32.3g, 0.12mol) was added dropwise at room temperature, and then Stir at room temperature for 2-8 hours, add 250 mL of saturated aqueous sodium bicarbonate solution, extract, collect the organic phase, concentrate under reduced pressure, and dry in vacuo to obtain 68.72 g of the compound of formula III, with a molar yield of 91.2% and an HPLC purity of 99.8% .

Embodiment 2

[0038] Embodiment 2: the preparation of formula III compound

[0039] The compound of formula IV (50 g, 0.11 mol) was dissolved in 200 mL of toluene, 4-dimethylaminopyridine (26.8 g, 0.22 mol) was added, and diphenoxyphosphoryl chloride (32.3 g, 0.12 mol) was added dropwise at room temperature, Stir at room temperature for 2 to 8 hours, add 250 mL of saturated aqueous sodium bicarbonate solution, extract, collect the organic phase, concentrate under reduced pressure, and dry in vacuo to obtain 70.3 g of the compound of formula III, with a molar yield of 92.6%, and an HPLC purity of 99.6%.

Embodiment 3

[0040] Embodiment 3: the preparation of formula I compound

[0041]

[0042] Add the compound of formula II (12.4g, 0.08mol) into 270mL dimethyl sulfoxide, add sodium tert-butoxide (16.3g, 0.17mol) in batches at 20-25°C, stir at room temperature for 0.5-3 hours, and then Add the compound of formula III (45 g, 0.07 mol), then stir the reaction at room temperature for 2 to 8 hours, add water to quench the reaction, extract, collect the organic phase, concentrate under reduced pressure, and dry in vacuo to obtain 37.5 g of the compound of formula I, mol The yield was 98.3%, and the HPLC purity was 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com