Jacking apparatus specially used for electric reactor pillar porcelain insulator replacement

A technology of jacking devices and reactors, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of waste of materials and energy, unusable, complicated jacking devices, etc., to reduce waste, avoid static electricity and frictional heat, and operate powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

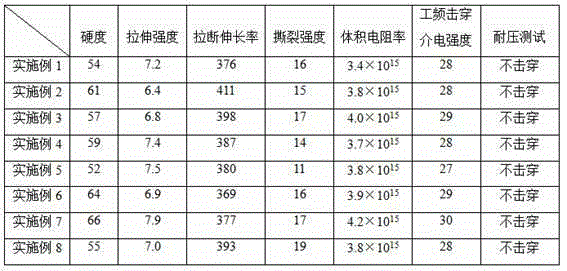

Embodiment 1

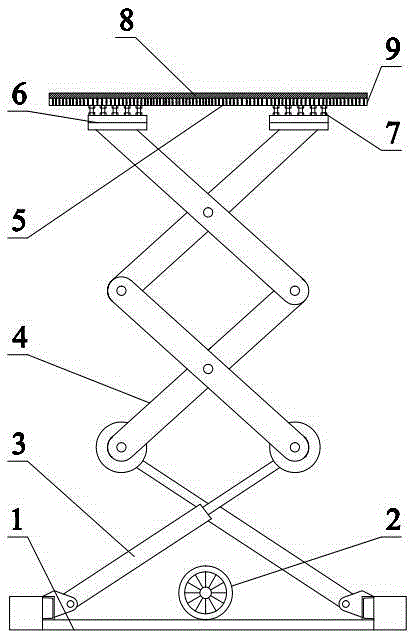

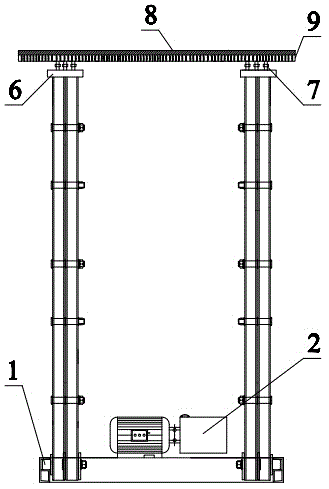

[0030] Such as figure 1 and 2 As shown in the figure, a special jacking device for reactor pillar porcelain bottle replacement includes a bracket chassis 1, a combined hydraulic pump 2, a hydraulic jacking cylinder 3 and a jacking platform 5, and also includes several pairs of vertically distributed and hinged support rods 4 in the middle. , the ends of each pair of adjacent poles 4 are connected to each other through sliding bearings, and the lifting cylinder drives the poles 4 to expand and contract up and down, which can support heavy objects, and the support points of the bracket parts can also transmit force from point to point, which overcomes the current situation. There are problems of time-consuming and labor-intensive, low bearing capacity and low safety factor when the column lifter is used for lifting.

[0031] The support chassis 1 is provided with a combined hydraulic pump 2 communicating with the hydraulic jacking cylinder 3, the upper ends of the uppermost pai...

Embodiment 2

[0043] The structure of embodiment 2 is roughly the same as that of embodiment 1, the difference is:

[0044] Among them, the insulating rubber layer 8 is made of the following raw materials in parts by weight: 70 parts of EPDM rubber, 26 parts of quartz sand, 30 parts of nano-active calcium carbonate, 8 parts of super lipophilic nano-alumina, coupling agent 4.5 parts, 15 parts of activator, 15 parts of paraffin base oil, 20 parts of fumed nano-silica, 1.2 parts of natural fiber.

[0045] Among them, natural fibers include kapok fiber and ramie fiber, wherein the weight ratio of kapok fiber and ramie fiber is 1:2.

[0046] The coupling agent includes an aluminate coupling agent and a titanate coupling agent, and the weight ratio of the aluminate coupling agent to the titanate coupling agent is 1:2.

[0047] The activator includes nano-silicon nitride powder, nano-zinc oxide powder and nano-magnesia powder, and the weight ratio of nano-silicon nitride powder, nano-zinc oxide p...

Embodiment 3

[0055] The structure of embodiment 3 is roughly the same as that of embodiment 1, the difference is:

[0056] Among them, the insulating rubber layer 8 is made of the following raw materials in parts by weight: 65 parts of EPDM rubber, 20 parts of quartz sand, 20 parts of nano-active calcium carbonate, 5 parts of super lipophilic nano-alumina, coupling agent 2 parts, 12 parts of activator, 10 parts of paraffin base oil, 15 parts of fumed nano-silica, 0.8 part of natural fiber.

[0057] Among them, natural fibers include kapok fiber and ramie fiber, wherein the weight ratio of kapok fiber and ramie fiber is 1:2.

[0058] The coupling agent includes an aluminate coupling agent and a titanate coupling agent, and the weight ratio of the aluminate coupling agent to the titanate coupling agent is 1:2.

[0059] The activator includes nano-silicon nitride powder, nano-zinc oxide powder and nano-magnesia powder, and the weight ratio of nano-silicon nitride powder, nano-zinc oxide powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com