High-temperature resistance and low-temperature resistance PBT heat conduction and heat dissipating material, preparation method and applications thereof

A heat-dissipating material, high and low temperature resistance technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor low temperature impact toughness, brittle materials, and reduced impact toughness, and achieve high impact toughness at high temperature and low temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of high and low temperature resistant PBT heat conducting material includes the steps:

[0025] 1) First use surface activator to modify the surface of the thermal conductive agent;

[0026] 2) Then mix the modified thermally conductive agent obtained in the previous step with other raw materials uniformly;

[0027] 3) Extrusion and granulation by twin screw extruder.

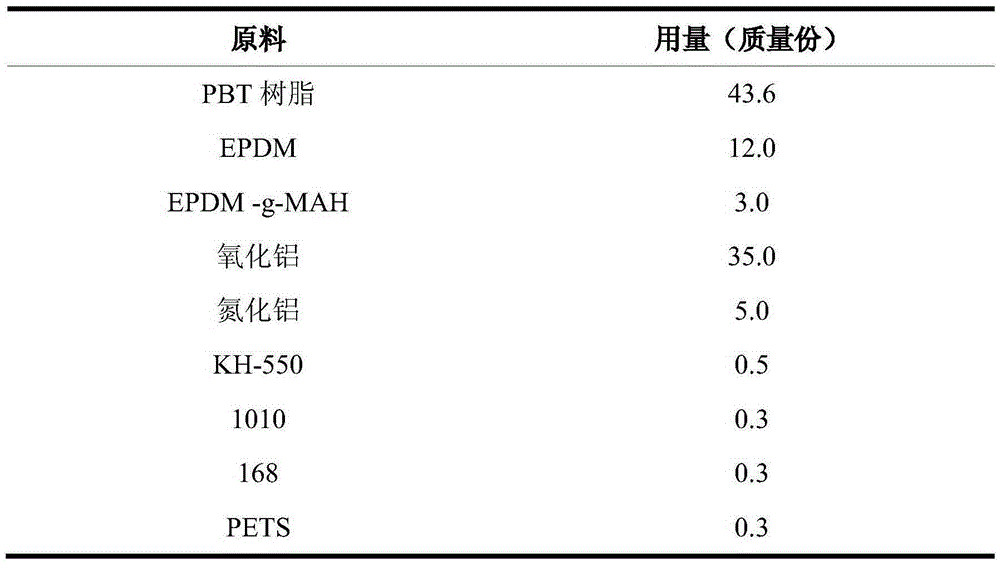

Embodiment 1

[0030] A high and low temperature resistant PBT heat dissipation material, its formula composition is as follows:

[0031] Table 1: High and low temperature resistant PBT heat dissipation material formula composition table

[0032]

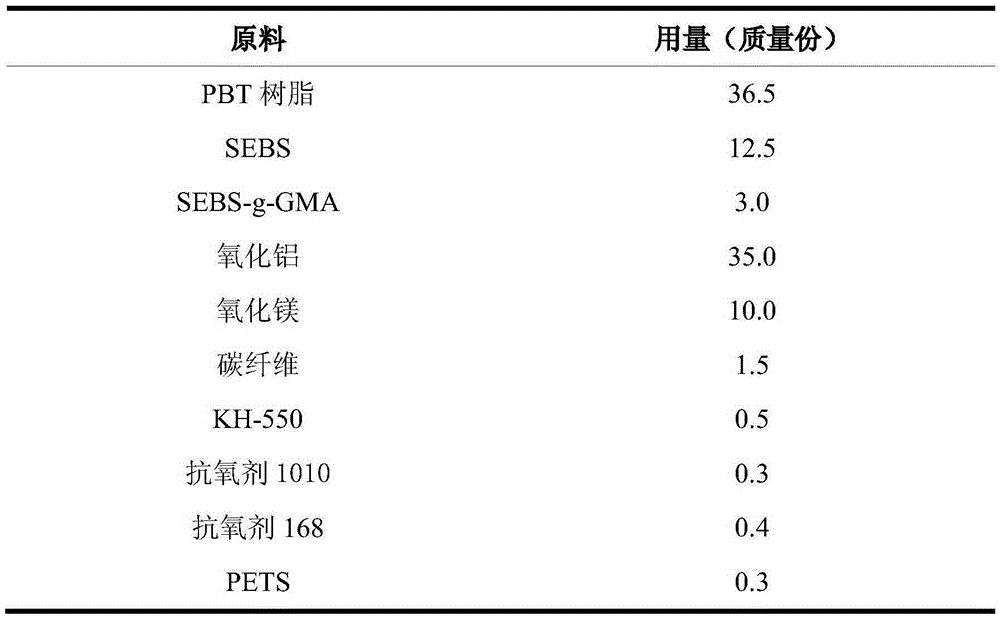

Embodiment 2

[0034] A high and low temperature resistant PBT heat conduction material, its formula composition is as follows:

[0035] Table 2: High and low temperature resistant PBT heat dissipation material formula composition table

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com