A method for extracting gelatin by using waste capsule shells

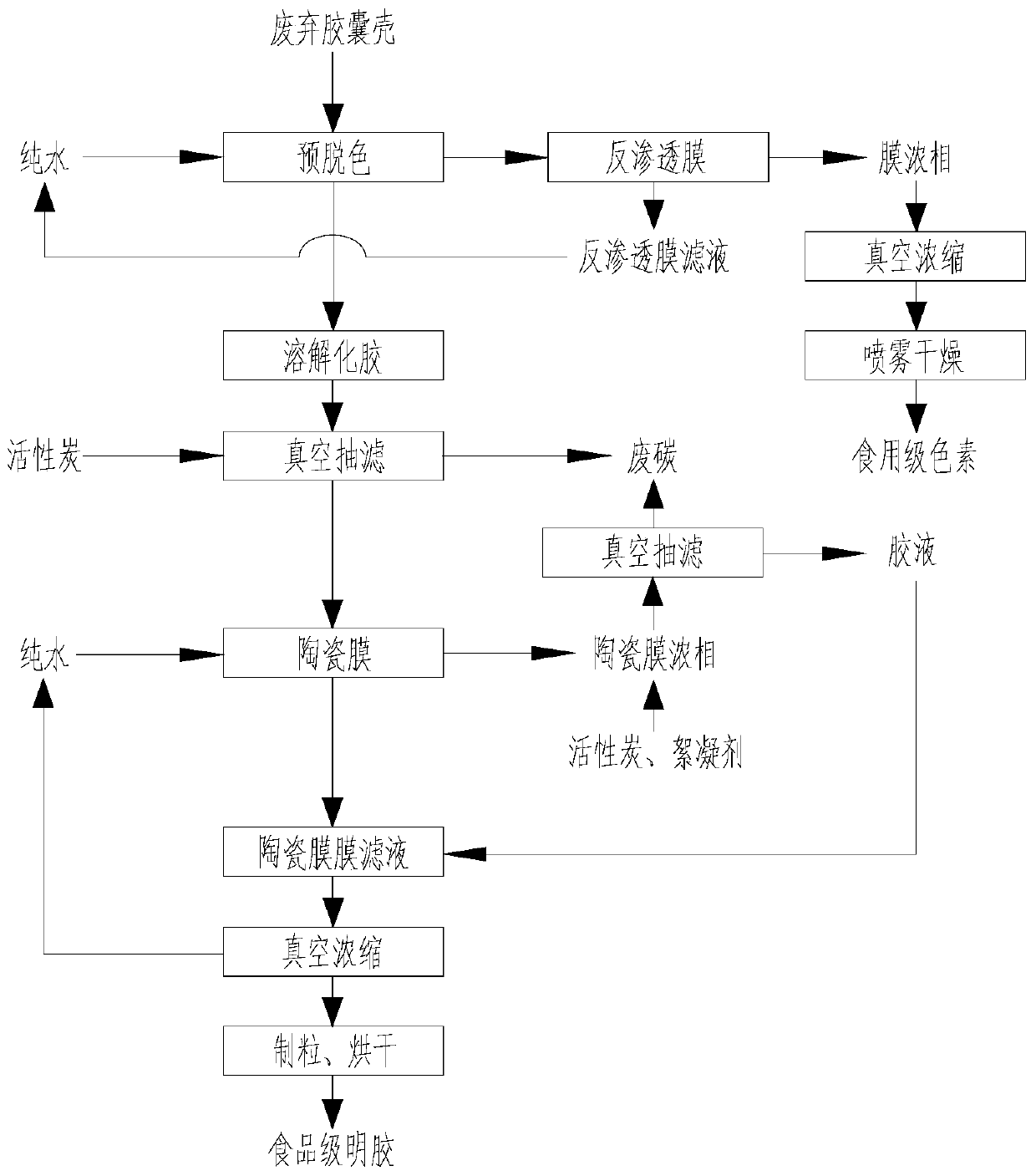

A technology of capsule shell and gelatin, which is applied in the field of gelatin extraction, can solve the problems of large environmental pollution, high recovery cost, large amount of diatomite and flocculant, etc., and achieves the effects of simple extraction process operation and high extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step (1): Weigh 10 kg of dry waste capsule shells, rinse them with pure water in advance, use 20L of pure water for each rinse, rinse 4 times, and rinse with water for later use;

[0037] Step (2): Add the rinsed spent capsule shells into pure water and completely dissolve them in a water bath at 60°C to obtain glue; control the amount of water added so that the specific gravity of the glue is controlled at 1.009 at 50°C.

[0038] Step (3): the rinsing water in the step (1) is filtered by a reverse osmosis membrane, the reverse osmosis membrane aperture is 1nm, the inlet pressure is 0.28Mpa, the outlet pressure is 0.18Mpa, and the membrane flux is 18LMH to obtain the reverse osmosis permeate and reverse osmosis retention solution; the reverse osmosis retention solution is vacuum concentrated to a dry matter content of 37%, the temperature is controlled at 70°C, and spray drying is carried out, the inlet air temperature is 200°C, and the outlet air temperature is 90°C to ...

Embodiment 2

[0046] Step (1): Weigh 10 kg of dry waste capsule shells, rinse them with pure water in advance, use 15 L of pure water for each rinse, rinse 5 times, and rinse with water for later use.

[0047] Step (2): Add the rinsed spent capsule shells into pure water and completely dissolve them in a water bath at 60°C to obtain a glue. Control the amount of water added so that the specific gravity of the glue is controlled at 1.010 at 50°C.

[0048] Step (3): The rinsing water in the step (1) is filtered by reverse osmosis, the reverse osmosis membrane aperture is 0.8nm, the inlet pressure is 0.28Mpa, the outlet pressure is 0.18Mpa, and the membrane flux is 16.3LMH to obtain the reverse osmosis membrane filtrate and reverse osmosis retention solution; the reverse osmosis retention solution is vacuum-concentrated to a dry matter mass content of 37%, the temperature is controlled at 70°C, spray-dried, the inlet air temperature is 200°C, and the outlet air temperature is 90°C to obtain foo...

Embodiment 3

[0056] Step (1): Weigh 10 kg of dry waste capsule shells, rinse them with pure water in advance, use 28L of pure water for each rinse, rinse 3 times, and rinse with water for later use.

[0057] Step (2): Add the rinsed waste capsule shells into pure water, set the volume to 25L in a water bath at 60°C until completely dissolved, and obtain the glue; control the amount of water added so that the specific gravity of the glue is controlled at 50°C At 1.009.

[0058] Step (3): The rinsing water in the step (1) is filtered by a reverse osmosis membrane, the reverse osmosis membrane pore size is 0.5nm, the inlet pressure is 0.28Mpa, the outlet pressure is 0.18Mpa, and the membrane flux is 15.1LMH to obtain reverse osmosis osmosis liquid and reverse osmosis retaining liquid; the reverse osmosis retaining liquid is subjected to vacuum concentration treatment, the dry matter mass content is 37%, the temperature is controlled at 70°C, the air inlet temperature is 200°C for spray drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com