A kind of tackifier for oil-based drilling fluid

A technology of oil-based drilling fluid and viscosifier, which is applied in drilling compositions, chemical instruments and methods to achieve the effects of high viscosity, low filtration vector and moderate dynamic shear force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Preparation of Viscosifier for Oil-based Drilling Fluid

[0016] The preparation method is as follows: pass bentonite through a 200-mesh sieve to make the particle size ≤ 75 μm; then add 850 kg of bentonite powder and 150 kg of modifier into the mixing tank and stir evenly, then sprinkle 50 kg of white oil evenly into the mixing tank, that is, Get the finished product.

[0017] The bentonite is sodium bentonite.

[0018] The modifying agent is stearyl amidopropyl trimethyl ammonium chloride.

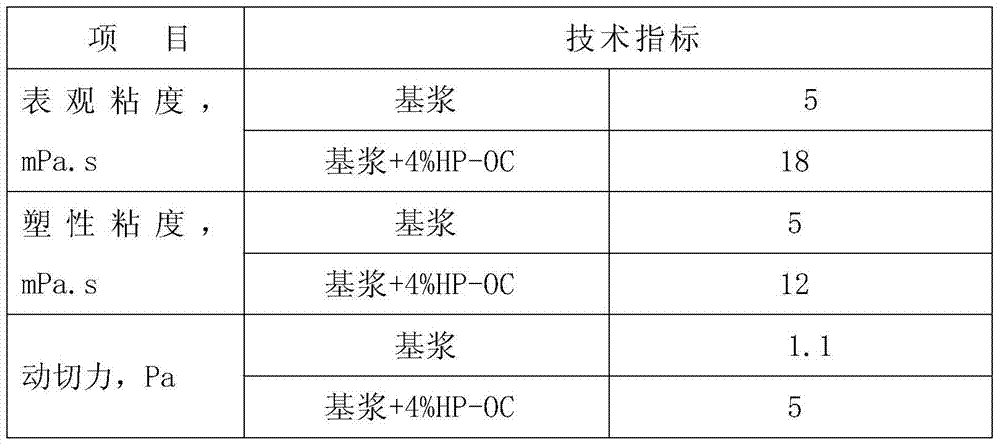

[0019] The oil-based drilling fluid viscosifier prepared by the above method is added to the base slurry to make drilling fluid (4% addition), and the performance index of the drilling fluid is as shown in Table 1. As can be seen from Table 1, the viscosifier of the present invention , can significantly improve the apparent viscosity, plastic viscosity, dynamic shear force.

[0020]

Embodiment 2

[0021] Example 2 Preparation of Viscosifier for Oil-based Drilling Fluid

[0022] The preparation method is as follows: pass bentonite through a 200-mesh sieve to make the particle size ≤ 75 μm; then add 800 kg of bentonite powder and 170 kg of modifier into the mixing tank and stir evenly, then sprinkle 55 kg of white oil evenly into the mixing tank, that is, Get the finished product.

[0023] The bentonite is sodium bentonite.

[0024] The modifier is cetyl amidopropyl dimethyl dodecyl ammonium chloride.

Embodiment 3

[0025] Example 3 Preparation of Viscosifier for Oil-based Drilling Fluid

[0026] The preparation method is as follows: pass bentonite through a 200-mesh sieve to make the particle size ≤ 75 μm; then add 900 kg of bentonite powder and 130 kg of modifier into the mixing tank and stir evenly, then sprinkle 45 kg of white oil evenly into the mixing tank, that is, Get the finished product.

[0027] The bentonite is sodium bentonite.

[0028] The modifier is stearyl amidopropyl dimethyl dodecyl ammonium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com