Optical imaging method

An imaging method and optical technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of complex processing, high cost, difficult device manufacturing and processing, etc., and achieve simple information processing, simple manufacturing structure, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing and embodiment:

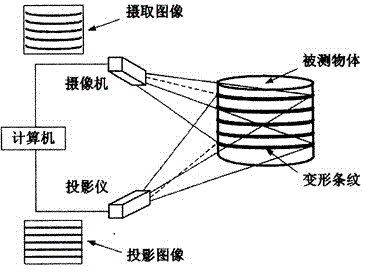

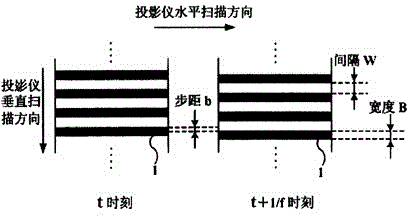

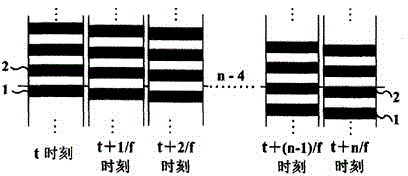

[0021] like figure 1 As shown, the computer controls the projector and the camera, and the projector emits a projection image and projects it onto the measured object, and the area array stripes in the projection image move in parallel according to the stepping frequency f. Deformation occurs when parallel area stripes are projected onto the object under test. The image of the deformed area array fringes is picked up by the camera, and collected to the computer through the image acquisition card. A common liquid crystal projector or the like may be used as the projector. The camera can adopt common CCD camera or CMOS camera etc. The effective field of view of the three-dimensional imaging is the intersection area of the field of view of the projector and the camera. Within the effective field of view of 3D imaging, the projected s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com