Evaluation value calibration method of equipment intelligent early warning system

An early warning system and calibration method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the impact assessment value, reduce the accuracy and effectiveness of the equipment early warning system, and cannot fundamentally change the redundancy of measuring points. It can improve the accuracy, ensure the real-time early warning capability, and achieve the effect of good versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

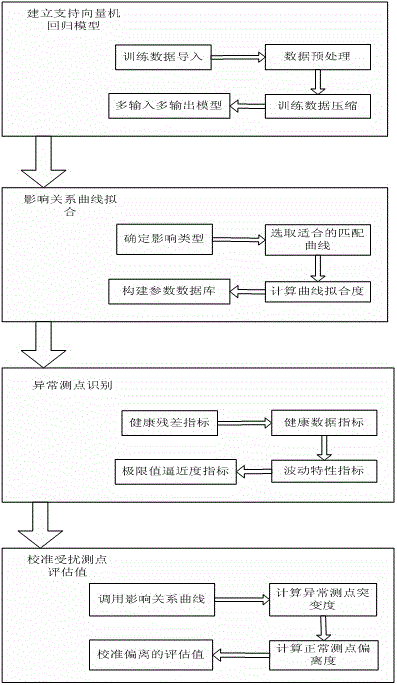

[0052] A kind of evaluation value calibration method of the equipment intelligent early warning system based on SVM, as attached figure 1 Shown, whole design of the present invention comprises following several processes:

[0053] Process 1 establishes an intelligent early warning model for equipment. This process mainly includes four main steps.

[0054] Step 1.1 Training data import

[0055] The selected training data is the historical health data of multiple measuring points of a single device. The general operation process is: read the historical operating status data of the relevant equipment for a sufficient time from the power plant database based on the selected measuring point; then use The set screening rules screen out the healthy equipment data in good operating condition from all the historical data as the training data for constructing the support vector machine regression model.

[0056] The filtering rules of the training data are to obtain healthy operation ...

Embodiment 2

[0163] In order to further illustrate the implementation process of the present invention, the present invention selects the important measuring point data of the A primary fan equipment in the No. 1 unit boiler auxiliary equipment of a certain thermal power plant to verify the beneficial assistance of the present invention to the early warning of equipment status.

[0164] The main steps of the present invention's evaluation value calibration method based on support vector machine to A primary fan are as follows:

[0165] 1. Using the historical health data of A primary fan to construct a multi-input and multi-output intelligent early warning model process

[0166] First, select the important parameter measurement points that will participate in the construction of the SVM regression model, and extract enough time data from the power plant database, and obtain training data according to the screening rules.

[0167] In this example, the measuring point of primary fan A is sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com