Adhesive composition for polarizing plate, adhesive sheet for polarizing plate, polarizing plate with adhesive layer, laminate, and flat panel display

A technology of adhesive layer and polarizing plate, applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problems of insufficient durability and processing characteristics of the adhesive layer, light leakage, etc., Excellent processing properties, stress relaxation, and good hardness properties are achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0164]

[0165] The polarizing plate with an adhesive layer of the present invention can be produced, for example, by the following methods (1) to (3).

[0166] (1) Coating the coating solution containing the adhesive composition for polarizing plates of the present invention on the release layer of the release film by a known method (die coating method, blade coating method, etc.), and drying the coating by heat drying. The solvent and the like contained in the cloth liquid are vaporized to form an adhesive layer with a desired thickness, and this is bonded to the polarizing plate.

[0167] (2) Coating the coating solution containing the composition of the present invention on a polarizing plate by a known method (die coating method, blade coating method, etc.), and vaporizing the solvent or the like contained in the coating solution by heat drying , form an adhesive layer with a desired thickness, and bond it to the release layer of the release film.

[0168] (3) Coat the...

Embodiment

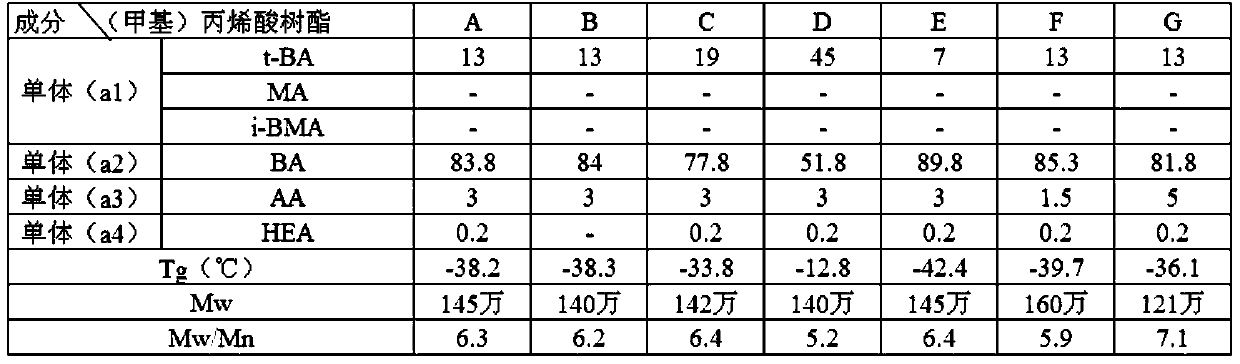

[0180] Hereinafter, the present invention will be described in detail through examples.

[0181] w ) and molecular weight distribution (M w / M n )>

[0182] The weight-average molecular weight of the (meth)acrylic resin was determined by GPC (gel permeation chromatography) in terms of standard polystyrene under the following conditions.

[0183]

[0184] Measuring device: HLC-8120GPC (manufactured by Tosoh Corporation)

[0185] GPC column structure: the following five columns (all manufactured by Tosoh Corporation)

[0186] (1) TSK-GEL HXL-H (guard column)

[0187] (2) TSK-GEL G7000HXL

[0188] (3) TSK-GEL GMHXL

[0189] (4) TSK-GEL GMHXL

[0190] (5) TSK-GEL G2500HXL

[0191] Sample concentration: dilute to 1.0mg / cm with tetrahydrofuran 3

[0192] Mobile phase solvent: tetrahydrofuran

[0193] Flow: 1.0cm 3 / min

[0194] Column temperature: 40°C

[0195] "Production example of (meth)acrylic resin"

[0196] In the reaction device equipped with stirrer, reflux ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com