Modified fiber ball filter for oil field

A technology of modified fibers and filters, applied in the field of modified fiber ball filters for oil fields, can solve the problems of insufficient water injection, low oil field water injection quality, and difficult cleaning, etc., and achieves good elasticity and high tensile strength. , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

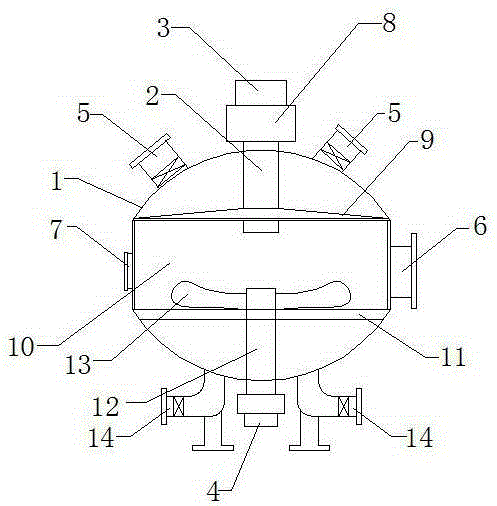

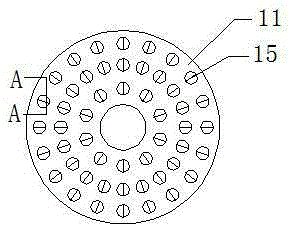

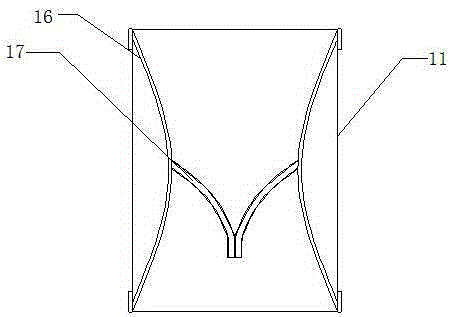

[0028] Such as figure 1 As shown, a modified fiber ball filter for oil field includes a housing 1, a main shaft 2 and a lifting device 3, and is characterized in that, both sides above the housing 1 are provided with a filtrate inlet 5, and the middle part of the housing 1 One side is provided with a filter packing inlet and outlet 6, the other side of the middle is provided with an observation hole 7, both sides of the lower part of the housing are provided with a filtrate outlet 14, and a power unit 8 is provided in the middle of the upper part of the housing 1, and the lower end An agitator 4 is provided in the middle, and a baffle 9 is provided on the main shaft 2; the main shaft 2 and the baffle 9 are placed in the housing 1, and a filter packing 10 is provided under the baffle 9, The bottom of the filter packing 10 is provided with a filter baffle 11, the bottom of the filter baffle 11 is provided with a rotating shaft 12, the upper end of the rotating shaft 12 is provid...

Embodiment 2

[0037] This embodiment is the same as Example 1, except that the modified fiber balls also contain natural cellulose fibers, polyester filaments and cotton filaments, and the natural cellulose fibers account for 1% of the modified fiber balls. The mass percentage is 20%, the mass percentage of the polyester yarn accounting for the modified fiber ball is 9%, the cotton yarn accounting for the mass percentage of the modified fiber ball is 15%, and the modified polyester amide The mass percent that fiber silk accounts for described modified fiber ball is 56%, and the preparation method of described modified fiber ball comprises the following steps:

[0038] Step 1. After shaping the modified polyester fiber filaments, natural cellulose fibers and polyester filaments into fiber bundles according to the set ratio, use multiple supporting fixtures to support the two ends of the fiber bundles and tighten them , so that the fiber bundles are linear;

[0039] After step 2 and step 1 a...

Embodiment 3

[0042] This embodiment is the same as Embodiment 1 and Embodiment 2, except that the modified fiber balls also contain natural cellulose fibers, polyester filaments and cotton filaments, and the natural cellulose fibers account for the modified fiber balls. The mass percentage of the modified fiber ball is 16%, the polyester yarn accounts for 8% of the modified fiber ball, and the cotton yarn accounts for 12% of the modified fiber ball. The mass percentage that permanent polyamide ester fiber silk accounts for described modified fiber ball is 64%, and the preparation method of described modified fiber ball comprises the following steps:

[0043] Step 1. After shaping the modified polyester fiber filaments, natural cellulose fibers and polyester filaments into fiber bundles according to the set ratio, use multiple supporting fixtures to support the two ends of the fiber bundles and tighten them , so that the fiber bundles are linear;

[0044] After step 2 and step 1 are comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com