Preparation method for mesoporous carbon with high nitrogen-doped content

A technology of mesoporous carbon and high nitrogen, which is applied in the field of preparation of mesoporous carbon with high nitrogen doping content, can solve the problems of difficulty in adjusting the hole wall thickness of the mesoporous silicon oxide template, restricting practical application, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

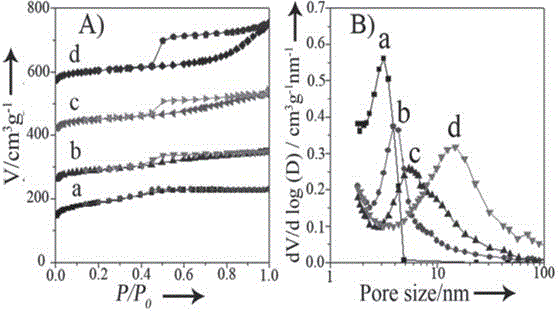

Embodiment 1

[0016] Mix 1 gram of surfactant F127 with 0.2 gram of melamine, 3 gram of low molecular weight phenolic resin and 10 gram of ethanol, stir evenly, then put in a fume hood to let the ethanol volatilize completely. The obtained compound was aged at 100°C for 24 hours, then placed in a muffle furnace, carbonized at 600°C for 2 hours in a nitrogen atmosphere, cooled to room temperature, and then taken out to obtain mesoporous nitrogen-doped carbon.

Embodiment 2

[0018] Mix 1 gram of surfactant F108 with 0.3 gram of polyacrylonitrile, 7 gram of low molecular weight phenolic resin and 50 gram of ethanol, stir evenly, and then put it in a fume hood to let the ethanol volatilize completely. The obtained compound was aged at 100°C for 24 hours, then placed in a muffle furnace, carbonized at 750°C for 2 hours in a nitrogen atmosphere, cooled to room temperature, and then taken out to obtain mesoporous nitrogen-doped carbon.

Embodiment 3

[0020] Mix 1 gram of surfactant P123 with 0.5 gram of polypyrrole, 10 grams of low-molecular-weight phenolic resin and 80 grams of ethanol, stir evenly, and then put it in a fume hood to let the ethanol evaporate completely. The obtained compound was aged at 100°C for 24 hours, then placed in a muffle furnace, carbonized at 800°C for 2 hours in a nitrogen atmosphere, cooled to room temperature, and then taken out to obtain mesoporous nitrogen-doped carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com