High weather resistance antireflection glass

A technology of anti-reflection glass and high weather resistance, which is applied in the field of optical glass, can solve the problem of glass desodination, etc., achieve excellent anti-reflection ability, increase aging resistance, and widely use the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

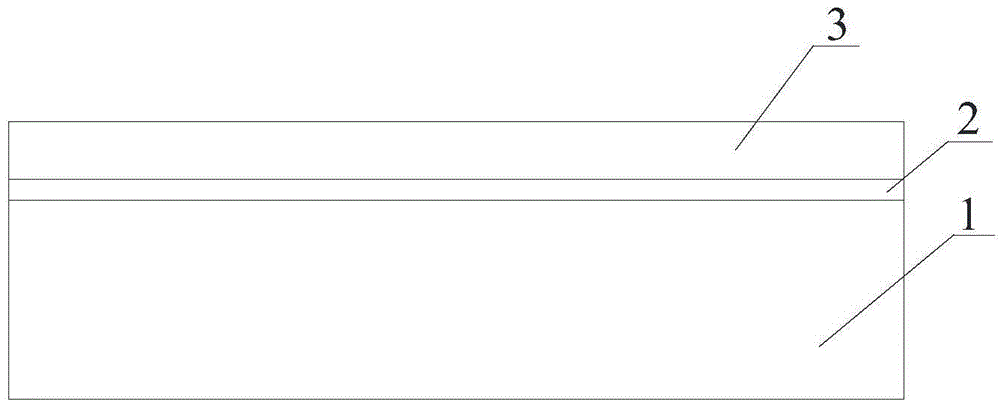

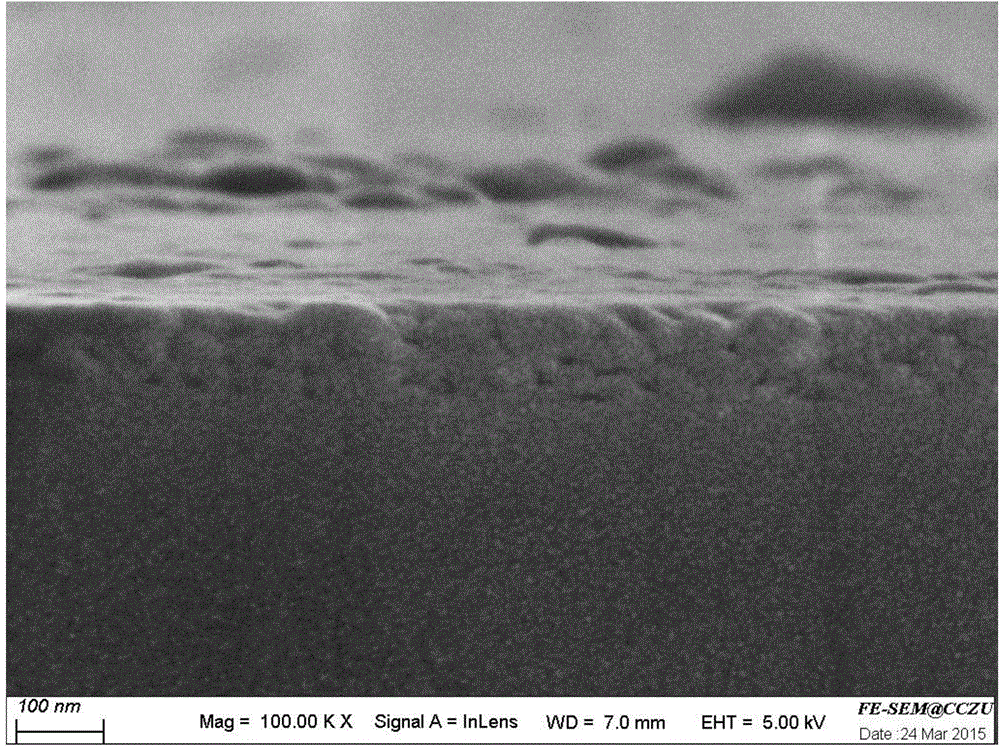

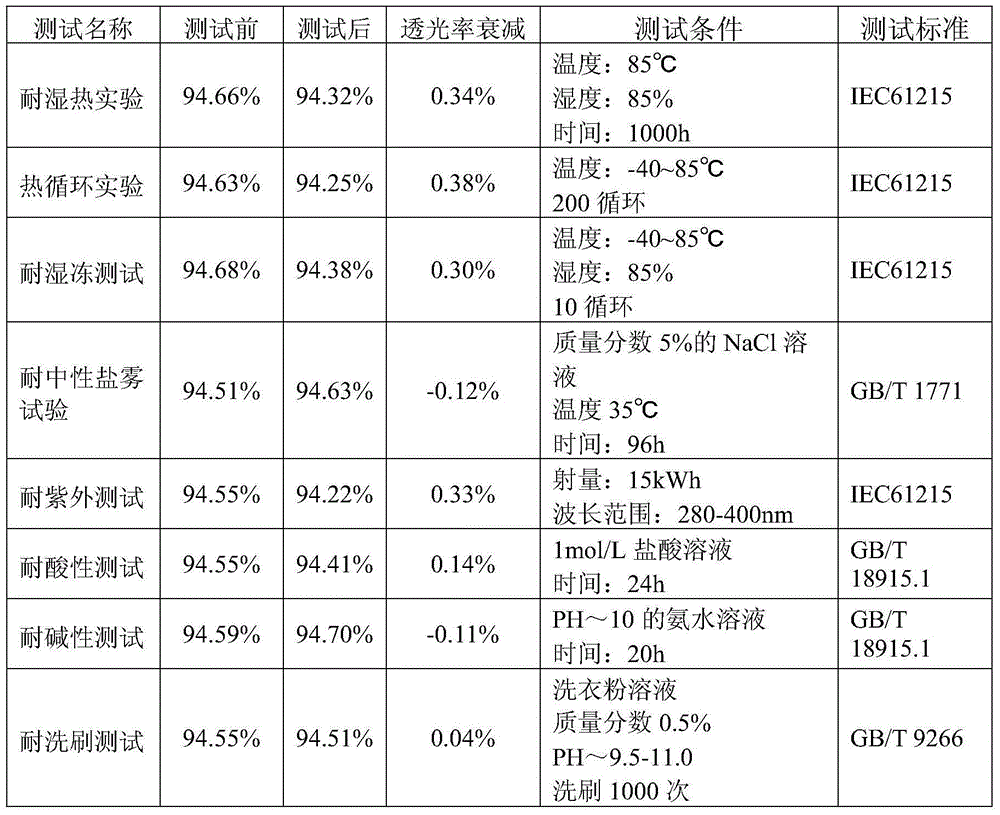

[0019] Such as figure 1 As shown, the anti-reflection glass with high weather resistance includes an anti-reflection layer 3, an anti-de-sodium layer 2 and a glass substrate 1 from top to bottom. The thickness of the anti-reflection layer 3 is controlled to be 120 nm, the porosity is 30%, and the refractive index is 1.25-1.30. The production process is as follows: firstly, the original glass substrate 1 is processed (edging / cleaning / appearance inspection), then the anti-de-sodium layer 2 is plated, and the anti-reflection layer 3 is plated, then tempered, and finally the finished product is inspected ( Appearance inspection / transmittance inspection). Coating film layer thickness test (testing instrument, J.A.Woollam): anti-de-sodium layer 2 thickness is 1.2nm, porosity 1.3%, refractive index 1.98, anti-reflection layer 3 thickness is 117.2nm, porosity 31.2%, refractive index The ratio is 1.29, and the SEM image of the film layer section is as follows figure 2 shown.

[00...

Embodiment 2

[0027] In embodiment 1, the anti-de-sodium layer 2 material is replaced by Al 2 o 3 , and control the thickness of the anti-sodium removal layer 2 to be less than 5nm and the porosity to be less than 5%, and control the thickness of the anti-reflection layer 3 to be 80nm and the porosity to be 55%. Other conditions are with embodiment 1.

[0028] Coating film thickness test (testing instrument, J.A.Woollam): anti-de-sodium layer 2 has a thickness of 4.8nm, a porosity of 4.9%, and an anti-reflection layer 3 has a thickness of 81.3nm, a porosity of 54.8%, and a refractive index of 1.23.

Embodiment 3

[0030] In embodiment 1, the anti-de-sodium layer 2 material is replaced by ZrO and Ta 2 o 3 The composite film layer (the molar ratio of the two is 1:1), the thickness of the anti-de-sodium layer 2 is controlled to be 0.1nm, and the porosity is less than 5%; the material of the anti-reflection layer 3 is replaced by Al 2 o 3 The film layer is controlled to have a thickness of 150nm, a porosity of 5%, and a refractive index of 1.3. Other conditions are with embodiment 1.

[0031] Coating film thickness test (testing instrument, J.A.Woollam): anti-de-sodium layer 2 has a thickness of 0.3nm, a porosity of 0.2%, and an anti-reflection layer 3 has a thickness of 148.3nm, a porosity of 6.2%, and a refractive index of 1.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com