Road-used multifunctional coating material with heat insulation and reduction and automobile exhaust treatment functions and preparation method of road-used multifunctional coating material

A multi-functional coating and automobile exhaust technology, applied in coatings, anti-corrosion coatings, etc., can solve problems that cannot fundamentally alleviate road surface problems, have no corresponding effective countermeasures, reduce road surface temperature, etc., and alleviate the heat island effect , Reduce road surface disease, reduce the effect of road surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

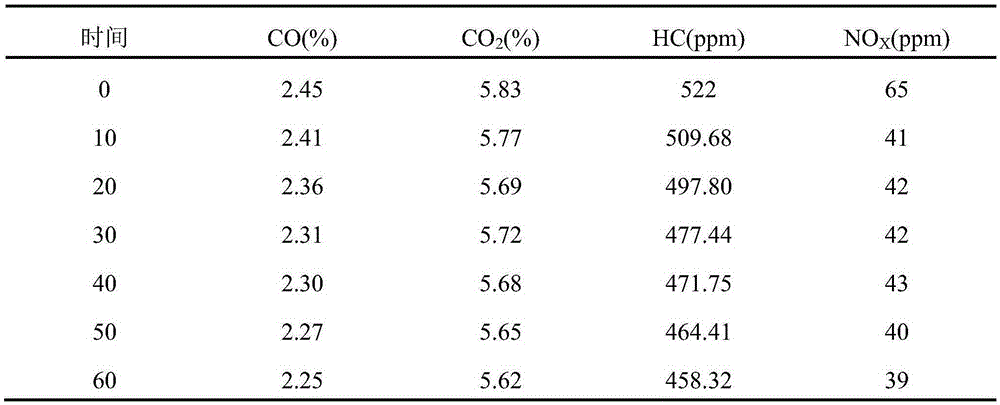

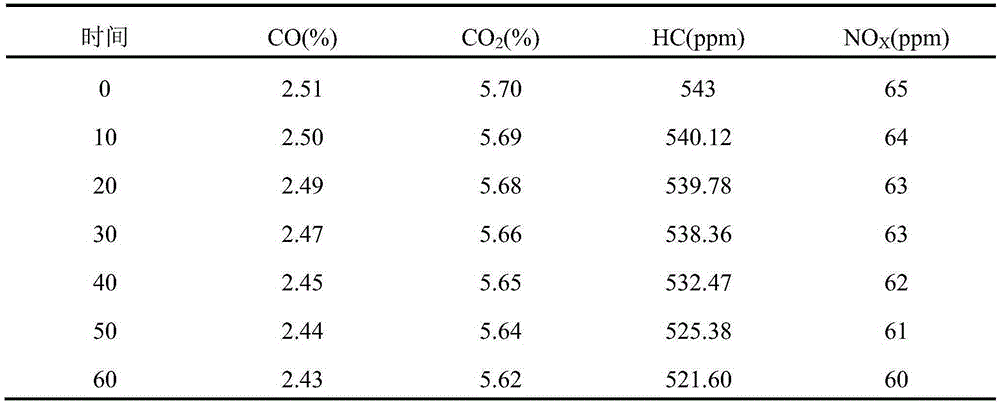

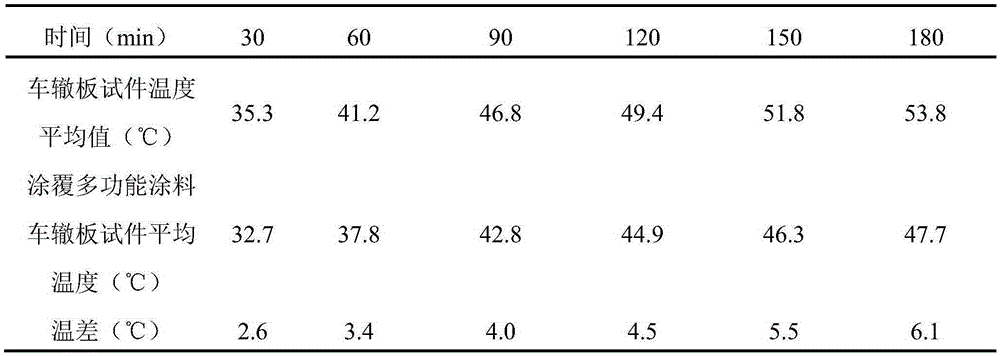

Examples

Embodiment 1

[0024] The road multifunctional coating material of the present embodiment having both heat insulation and cooling and automobile exhaust treatment is made up of the raw materials of the following proportions: in g, 55 g of silicon-acrylic emulsion, 20 g of water, iron-doped alumina load Nano titanium dioxide 8g, hollow glass microspheres 8g, titanium dioxide 7g, ultrafine diatomite 11g, propylene glycol 8g, defoamer 0.2g, leveling agent 0.2g, thickener 0.2g, wetting agent 0.2g, dispersant 0.7g.

[0025] Among them: the particle size of hollow glass beads is 250 mesh, the compressive strength is greater than 0.8MPa, the defoamer is BYK-052 defoamer, the leveling agent is BYK-333 leveling agent, the thickener is BYK-420 The thickener and wetting agent are BYK-378 wetting agent, and the dispersing agent is BYK-161 dispersing agent.

[0026] Its preparation method is realized by following steps:

[0027] (1) Weigh the defoamer, leveling agent, thickener, dispersant, wetting age...

Embodiment 2

[0030] The road multifunctional coating material of the present embodiment, which has both heat insulation and cooling and automobile exhaust treatment, is made up of the following raw materials: in g, 50 g of silicon acrylic emulsion, 15 g of water, iron-doped alumina load Nano titanium dioxide 5g, hollow glass microspheres 5g, titanium dioxide 5g, ultrafine diatomite 11g, propylene glycol 5g, defoamer 0.06g, leveling agent 0.06g, thickener 0.06g, wetting agent 0.12g, dispersant 0.6g.

[0031] Among them: the particle size of hollow glass beads is 200 mesh, the compressive strength is greater than 0.8MPa, the defoamer is BYK-141 defoamer, the leveling agent is BYK-306 leveling agent, the thickener is BYK-425 thickening The agent and wetting agent are BYK-331 wetting agent, and the dispersant is BYK-163 dispersant.

[0032] Its preparation method is realized by following steps:

[0033] (1) Weigh the defoamer, leveling agent, thickener, dispersant, wetting agent and propylen...

Embodiment 3

[0036] The road multi-functional coating material of the present embodiment having both heat insulation and cooling and automobile exhaust treatment is made up of the raw materials of the following proportions: in g, 60 g of silicon acrylic emulsion, 25 g of water, iron-doped alumina load Nano titanium dioxide 9g, hollow glass microspheres 9g, titanium dioxide 9g, ultrafine diatomaceous earth 14g, propylene glycol 9g, defoamer 0.57g, leveling agent 0.57g, thickener 0.57g, wetting agent 0.39g, dispersant 0.9g.

[0037] Among them: hollow glass microspheres require a particle size of 400 mesh and a compressive strength greater than 0.8MPa. The defoamer is BOK-X-401 defoamer, the leveling agent is BYK-306 leveling agent, and the thickener is BYK- 420 thickener and wetting agent are BYK-331 wetting agent, and the dispersant is BOK-F-501 dispersant.

[0038] Its preparation method is realized by following steps:

[0039] (1) Weigh the defoamer, leveling agent, thickener, dispersa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com