Al-Mg-Si aluminum alloy material for spinning hub and method for preparing spinning hub

A technology of aluminum alloy materials and spinning wheels, which is applied in the field of wheel hubs, can solve the problems of long production cycle, complex process, and high energy consumption, and achieve the effects of simplifying the production process, alleviating resource pressure, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

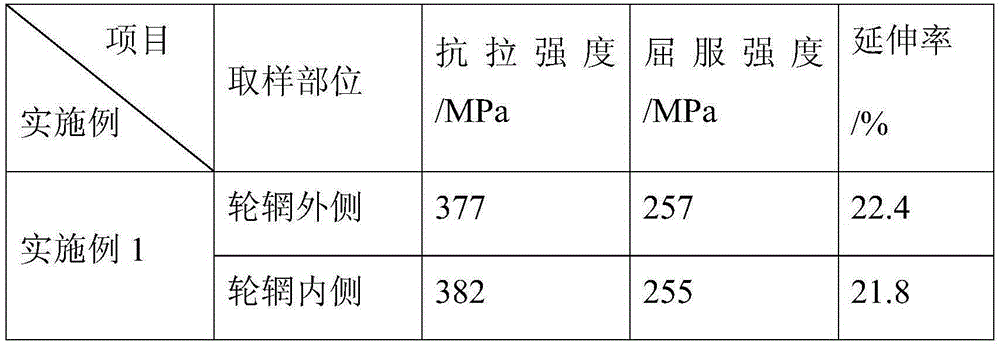

Embodiment 1

[0045] The chemical composition is Mg5.80wt%, Si0.25wt%, Mn0.60wt%, Fe0.35wt%, Cu0.07wt%, Cr0.25wt%, Zn0.25wt%, Ti0.12wt%, and the Al of balance ( The rest is the Al-Mg-Si series aluminum alloy of unavoidable impurity) according to the following method to prepare the spinning hub, comprising the following steps:

[0046] The first step: melting the Al-Mg-Si series aluminum alloy material and casting it into a slab;

[0047] Step 2: Sawing and milling the flat ingot, and then performing homogenization treatment. The temperature of the homogenization treatment is 500° C., and the treatment time is 8 hours.

[0048] Step 3: Carry out forging at room temperature to form the spokes of the hub, and obtain a straight tube with a spoke-shaped bottom; the spinning temperature is room temperature, the spindle speed of spinning is 600r / min, and the feed rate is 0.5mm / r.

[0049] Step 4: Spin the straight cylinder at room temperature to form the hub, rim and rim;

[0050] Step 5: Grinding...

Embodiment 2

[0052] The chemical composition is Mg2.00wt%, Si0.50wt%, Mn0.35wt%, Fe0.5wt%, Cu0.01wt%, Cr0.35wt%, Zn0.16wt%, Ti0.20wt%, and the Al of balance ( The rest is the Al-Mg-Si series aluminum alloy of unavoidable impurity) according to the following method to prepare the spinning hub, comprising the following steps:

[0053] The first step: melting the Al-Mg-Si series aluminum alloy material and casting it into a slab;

[0054] The second step: sawing and milling the flat ingot, and then performing homogenization treatment, the temperature of the homogenization treatment is 430° C., and the treatment time is 40 hours.

[0055] Step 3: Carry out forging at room temperature to form the spokes of the hub, and obtain a straight tube with a spoke-shaped bottom; the spinning temperature is room temperature, the spindle speed of spinning is 300r / min, and the feed rate is 2mm / r.

[0056] Step 4: Spin the straight cylinder at room temperature to form the hub, rim and rim;

[0057] Step 5:...

Embodiment 3

[0059] The chemical composition is Mg4.5wt%, Si0.38wt%, Mn0.48wt%, Fe0.42wt%, Cu0.03wt%, Cr0.3wt%, Zn0.2wt%, Ti0.16wt%, and the Al of balance ( The rest is the Al-Mg-Si series aluminum alloy of unavoidable impurity) according to the following method to prepare the spinning hub, comprising the following steps:

[0060] The first step: melting the Al-Mg-Si series aluminum alloy material and casting it into a slab;

[0061] Step 2: Sawing and milling the slab, and then performing homogenization treatment, the temperature of the homogenization treatment is 460°C, and the treatment time is 20 hours.

[0062] Step 3: Carry out forging at room temperature to form the spokes of the hub, and obtain a straight tube with a spoke-shaped bottom; the spinning temperature is room temperature, the spindle speed of spinning is 400r / min, and the feed rate is 1.2mm / r.

[0063] Step 4: Spin the straight cylinder at room temperature to form the hub, rim and rim;

[0064] Step 5: Grinding and pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com