Etched diffraction grating device with uniform channel loss and flat passband response

A diffraction grating and flat technology, applied in the field of integrated etched diffraction grating devices, can solve problems such as large insertion loss, achieve uniform loss, achieve flat passband response, and improve loss uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and example.

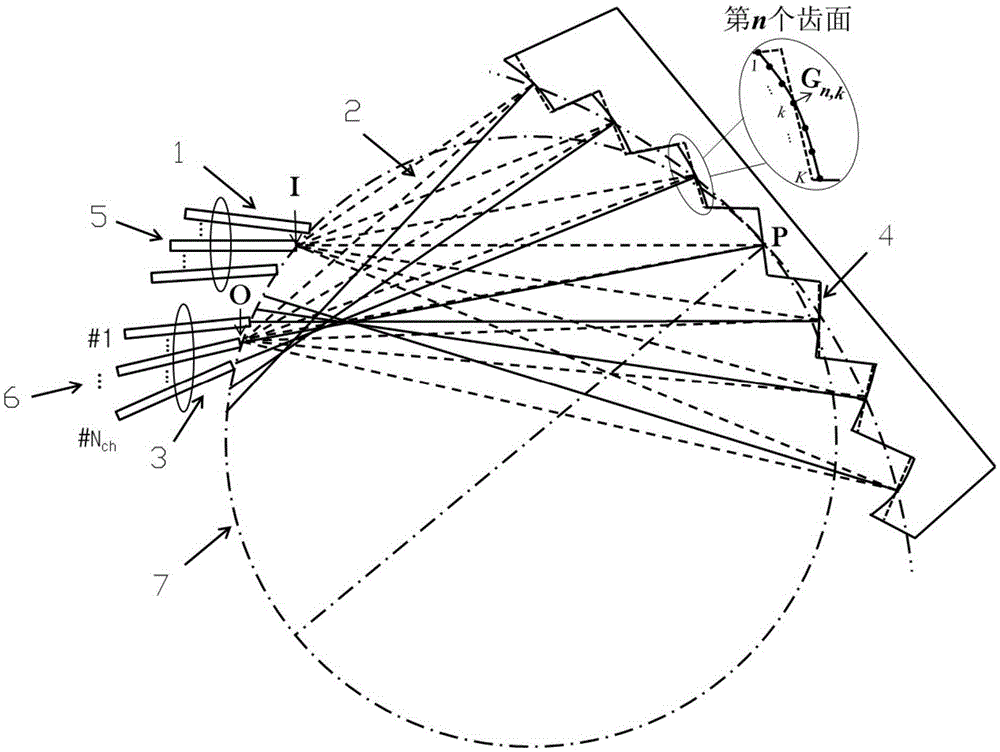

[0032] Such as figure 1 As shown, the present invention consists of at least one input waveguide 1, slab waveguide region 2, output waveguide array 3 and grating reflective tooth surface 4 to form an optical path structure. Reflected, and then received by the output waveguide 3 through the slab waveguide area 2, the total optical path from the input end point of the input waveguide in the slab waveguide area to the center of each grating reflection surface to the exit of the output waveguide in the output slab waveguide area is an arithmetic progression increment. Its optical path adopts a Rowland circle 7 structure, that is, the input waveguide 1 and the output waveguide array 3 are placed on the circumference of the Rowland circle 7, and the grating reflective tooth surface 4 is located on a circle whose radius is twice that of the Rowland circle 7 and is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com