Chromium based catalyst for dehydrofluorination, and preparation method and application thereof

A chromium-based catalyst, a technology for dehydrofluorination, which can be used in the preparation of dehydrohalogenation, etc., and can solve the problems of decreased production efficiency, low activity, and low conversion rate of HFC-152a.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Cr(NO 3 ) 3 9H 2 O is dissolved in a certain amount of water, and ammonia water is added as a precipitating agent under stirring, and the pH of the solution is adjusted to 9.0, so that the dissolved Cr 3+ It can be fully precipitated, and the formed slurry is filtered, washed, and dried at 110°C for 24 hours to obtain Cr(OH) 3 . The obtained Cr(OH) 3 It is ball-milled and mixed with MgO according to the mole percentages of Cr and Mg to be 50 mol % and 50 mol %, and pressed into tablets to obtain a catalyst precursor.

[0029] Put the catalyst precursor into a ф14*1000 carbon steel reaction tube, 2 Calcined at 300°C for 6 hours under the atmosphere, and introduced volume ratio HF:N 2 The mixed gas of 1:4 is fluorinated at 250°C for 2h, then the temperature is raised to 360°C at a rate of 1°C / min, and the fluorination is continued for 12h, and then fluorinated with pure HF for 4h to obtain a chromium-based catalyst.

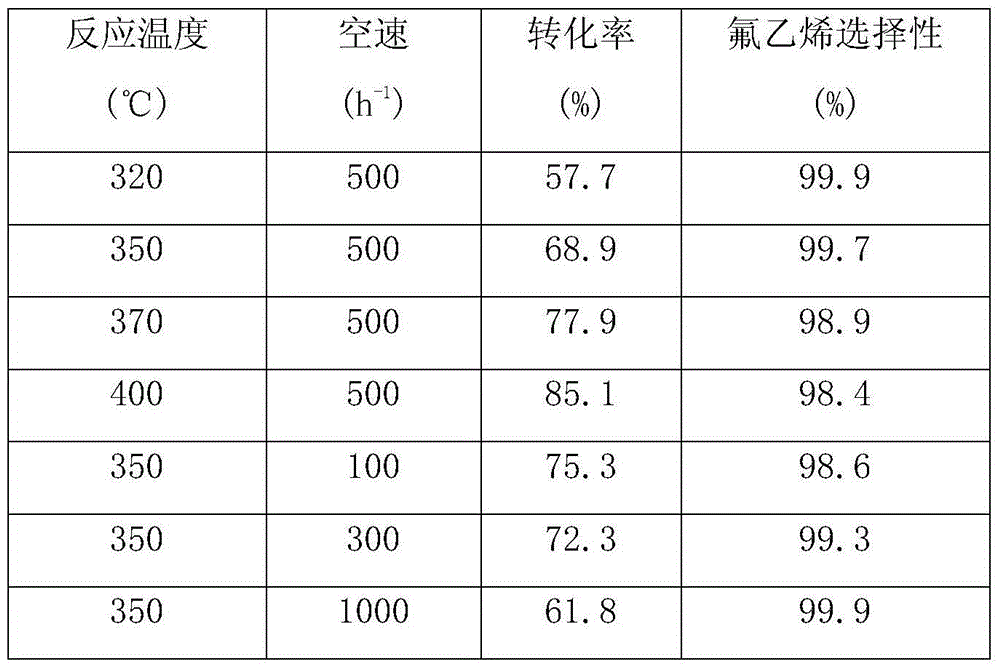

[0030] The prepared chromium-based catalyst is ...

Embodiment 2

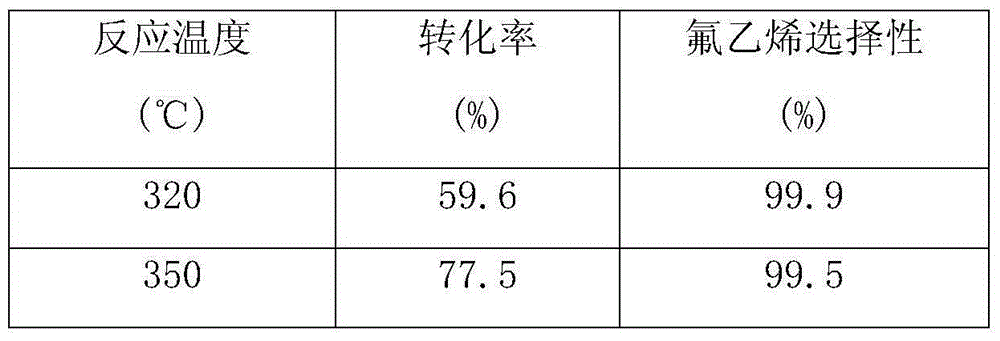

[0034] Chromium-based catalysts are prepared according to the method described in Example 1, but Cr(OH) 3 The mole percentage composition with MgO is adjusted to 30 mol% and 70 mol% to obtain the chromium-based catalyst of the present invention.

[0035] The prepared chromium-based catalyst was used in the dehydrofluorination reaction of 1,1-difluoroethane, and the reaction temperature was controlled at 350°C and the space velocity was 500h -1 , The conversion rate of 1,1-difluoroethane and the selectivity of vinyl fluoride are shown in Table 2.

[0036] Table 2

[0037] Reaction time

[0038] (h)

Embodiment 3

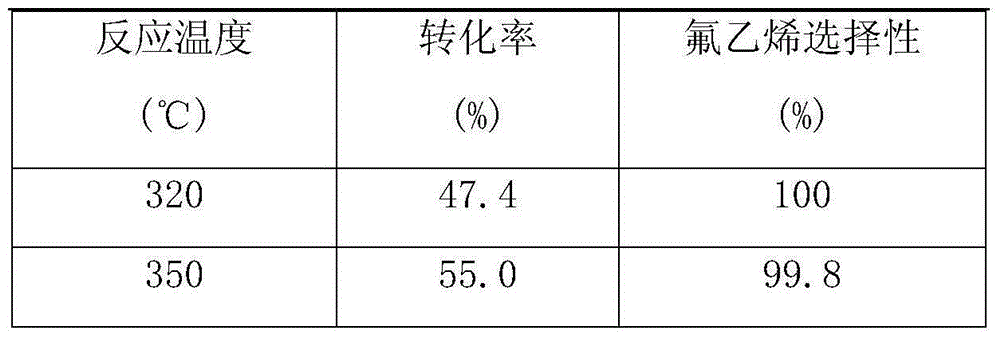

[0040] KCr(SO 4 ) 2 12H 2 O is dissolved in a certain amount of water, and ammonia water is added as a precipitating agent under stirring, and the pH of the solution is adjusted to 8.5, so that the dissolved Cr 3+ It can be fully precipitated, and the formed slurry is filtered, washed, and dried at 150°C for 24 hours to obtain Cr(OH) 3 . The obtained Cr(OH) 3 with AlF 3 The mole percentages of Cr and Al are divided into 75 mol % and 25 mol % for ball milling and mixing, and tablet molding to obtain a catalyst precursor.

[0041] Put the catalyst precursor into a ф14*1000 carbon steel reaction tube, 2 Calcined at 400°C for 6 hours under the atmosphere, and introduced volume ratio HF:N 2 The 1:2 mixed gas is fluorinated at 250°C for 2 hours, then the temperature is raised to 360°C at a rate of 1°C / min, the fluorination is continued for 12 hours, and then pure HF is passed through for fluorination for 4 hours to obtain the chromium-based catalyst.

[0042] The prepared c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com