Laser-shock-based device for deformation connection of metal sheets and method thereof

A metal sheet, laser shock technology, applied in laser welding equipment, auxiliary devices, metal processing equipment and other directions, can solve the problems of increasing the internal deformation space, high manufacturing cost of micro punches, difficult to apply, etc., to improve production efficiency, Guaranteed accuracy and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

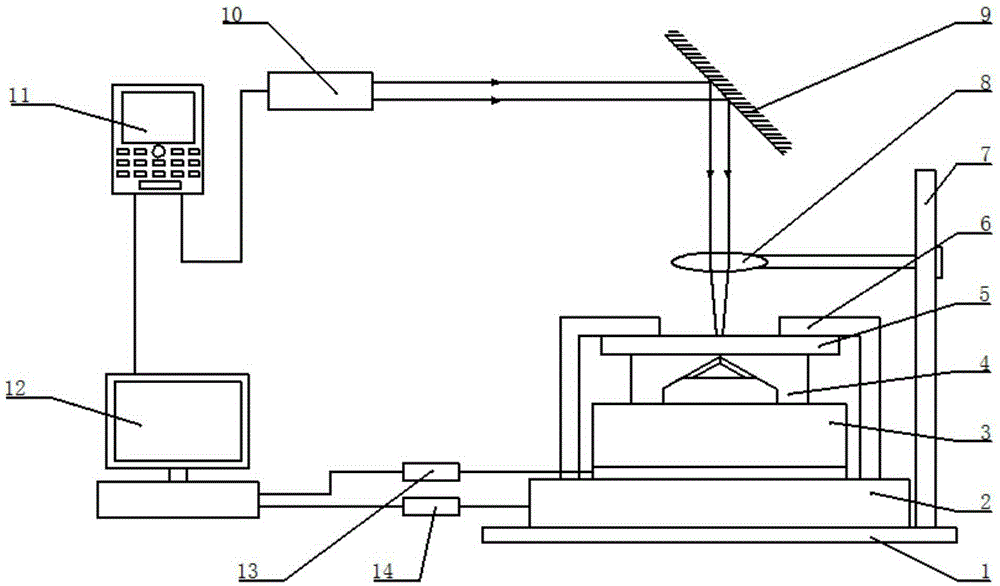

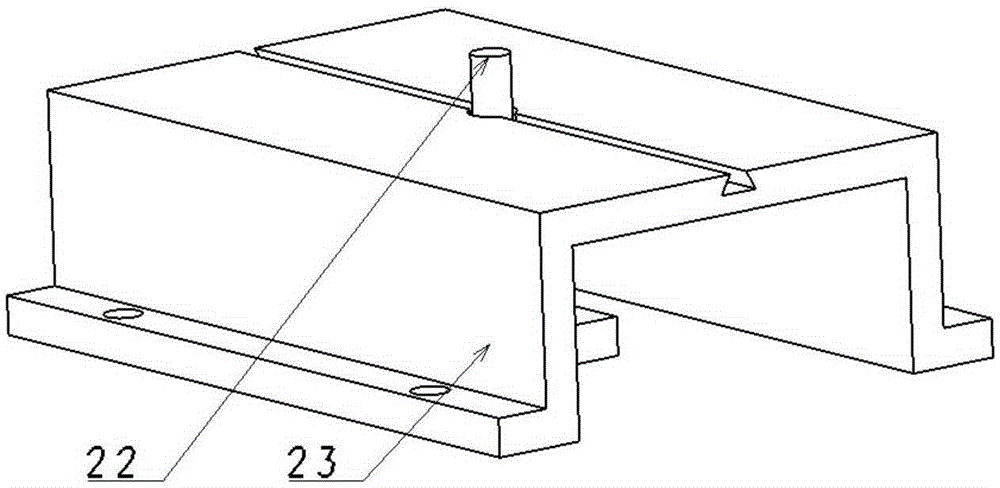

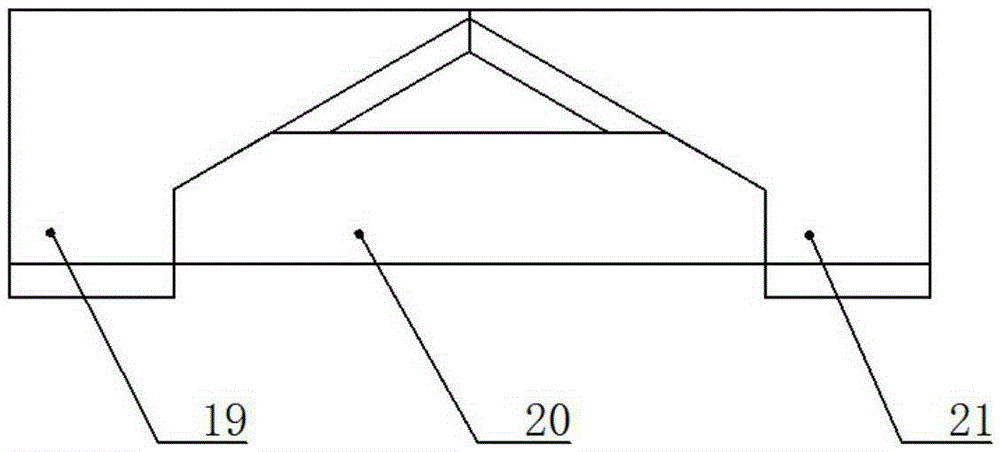

[0035] The structure of the metal sheet deformation connection device based on laser shock in the present invention is as follows: figure 1 As shown, including laser emission system, control system, deformation connection system.

[0036] The laser emitting system is composed of a base 1, a lens bracket 7, a pulse laser 10, a reflector 9, and an adjustable focus lens 8; the lens bracket 7 is fixed on the base 1, and the adjustable focus lens 8 is installed on the lens bracket 7 and positioned on the On the optical path of the laser after mirror reflection; the laser light emitted by the pulse laser 10 is irradiated to the surface of the workpiece system 5 through the reflection of the mirror 9 and the focusing of the adjustable focusing lens 8 . The vertical rod and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com