Nanometer-precision optical curved-face ion beam processing method based on non-linear modeling

A processing method and nonlinear model technology, which is applied in the field of ion beam processing of nano-precision optical surfaces, can solve problems such as projection deformation, accurate solution of affecting dwell time, and removal of models that are no longer universal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The following is based on the caliber Taking a curved optical component with a vertex curvature radius of 16 mm and a workpiece material of fused silica as an example, the ion beam processing method for nanometer-precision optical curved surfaces of the present invention will be further described in detail.

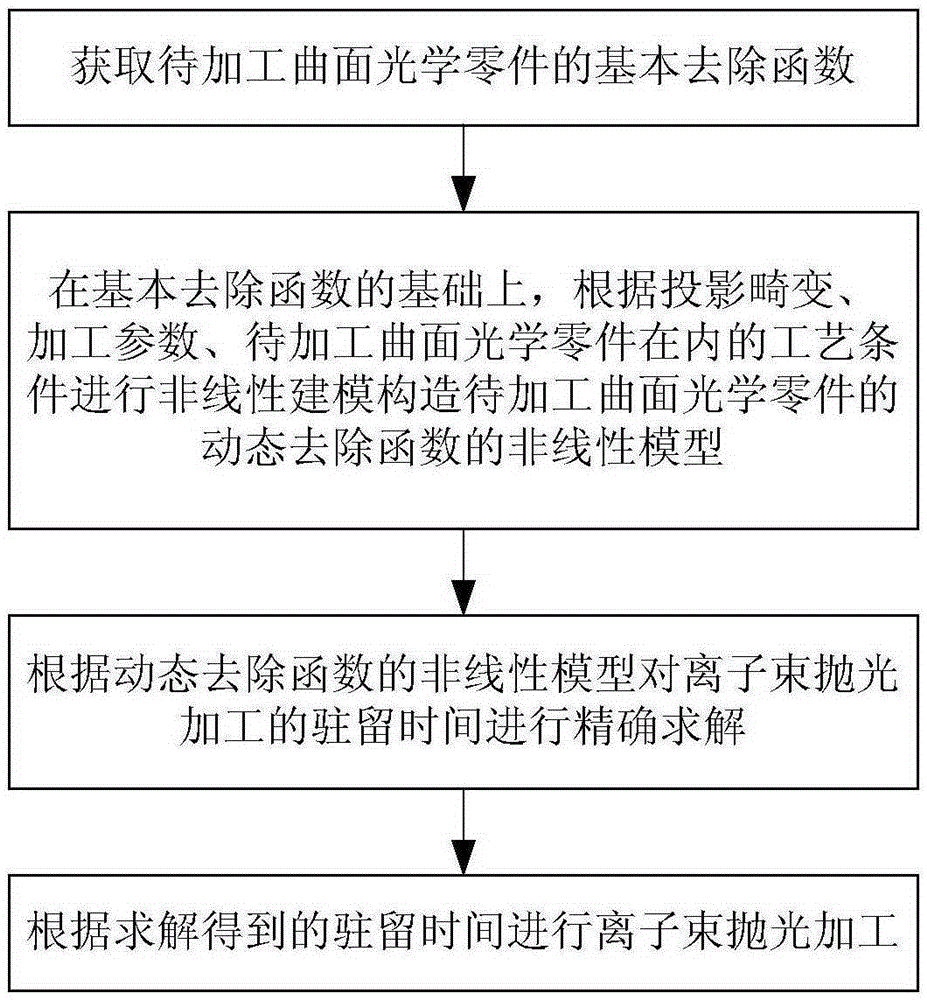

[0067] Such as figure 1 As shown, the steps of the nano-accuracy optical surface ion beam processing method based on nonlinear modeling in this embodiment include:

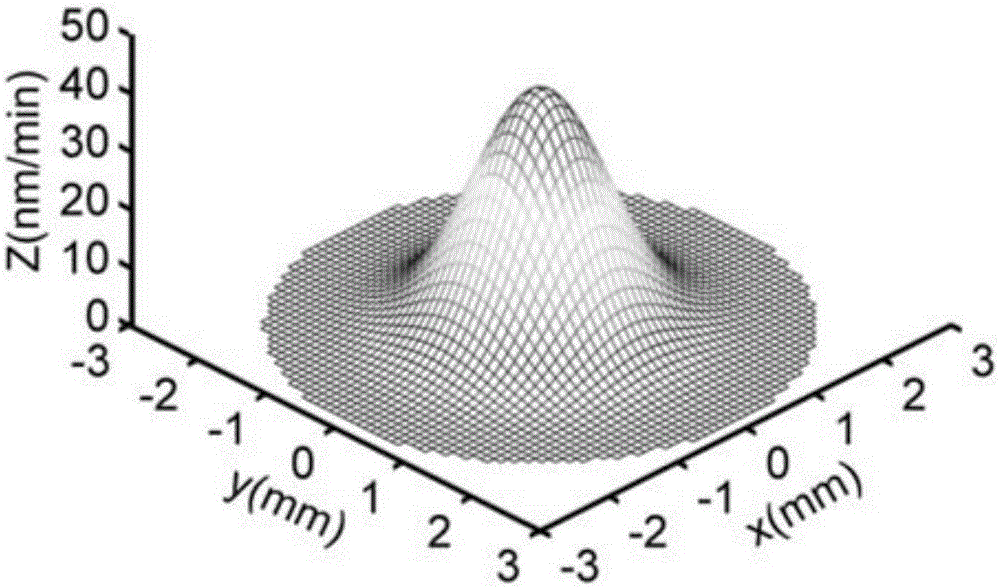

[0068] 1) Obtain the basic removal function of the curved surface optical part to be processed;

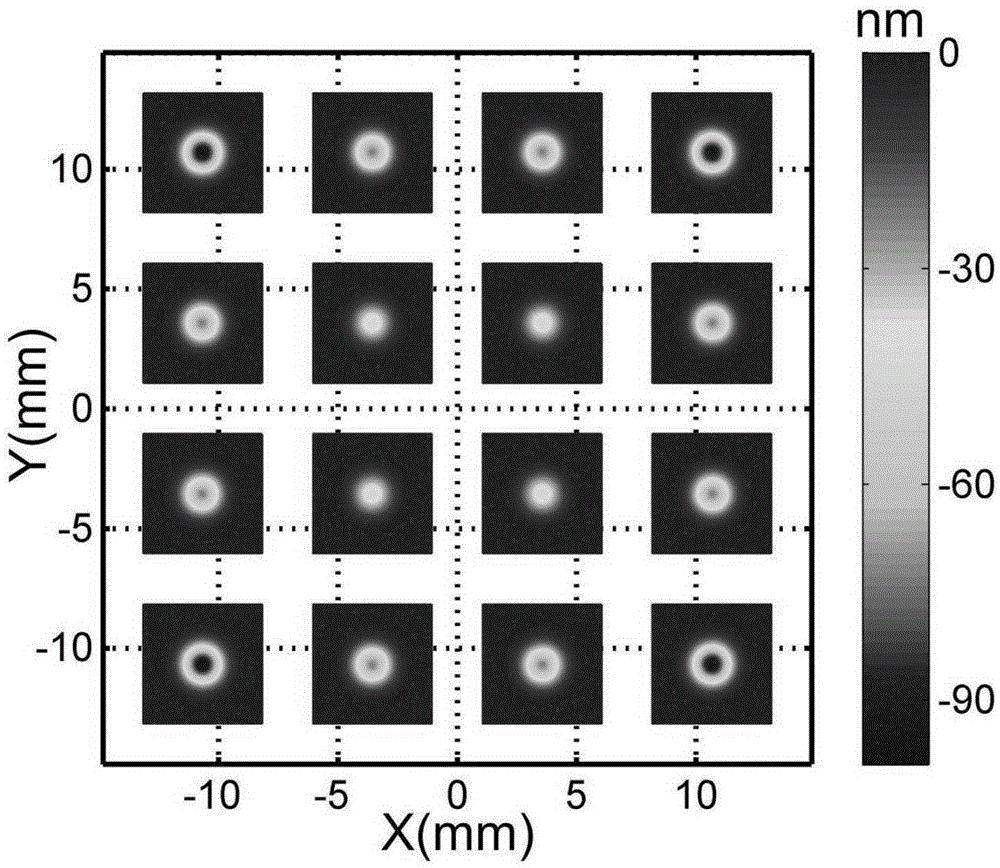

[0069] 2) On the basis of the basic removal function, according to the process conditions including projection distortion, processing parameters, and optical parts to be processed, nonlinear modeling is carried out to construct a nonlinear model of the dynamic removal function of the optical parts to be processed;

[0070] 3) Accurately solve the dwell time of ion beam polishing according to the nonline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com