Preliminary-grinding and leakage-proof transport device for lime kiln

A transportation device, lime kiln technology, applied in transportation and packaging, conveyor objects, rollers, etc., can solve the problems of limited transportation volume, easy falling of particles and powders, and inconsistency in transportation by transportation trolleys. The effect of adjusting the angle, avoiding material falling, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

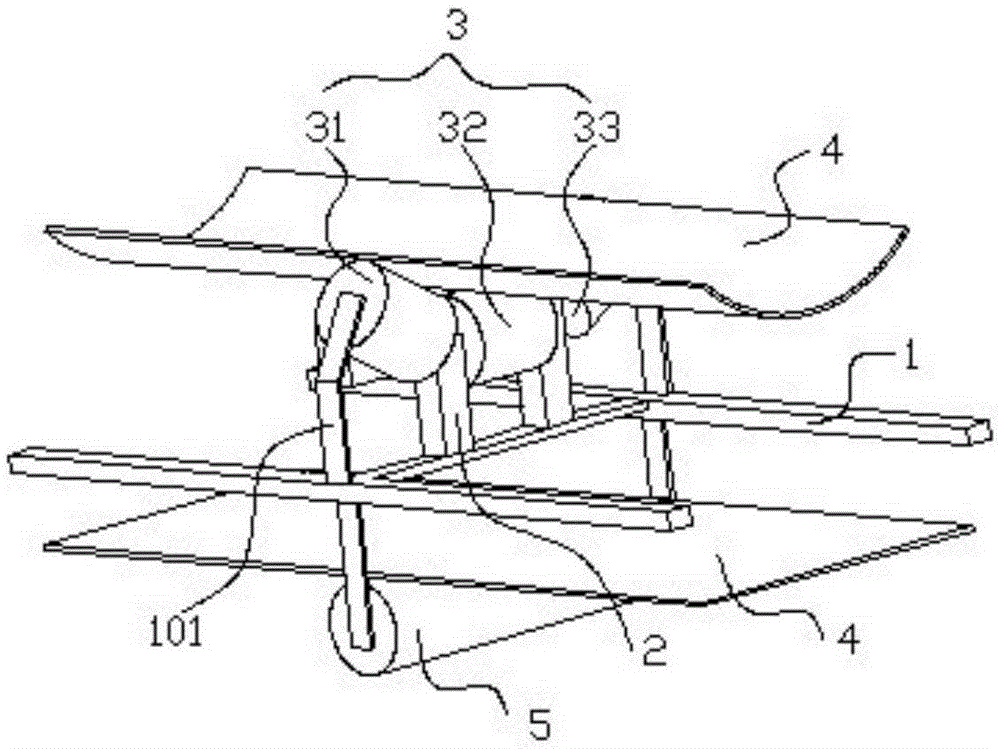

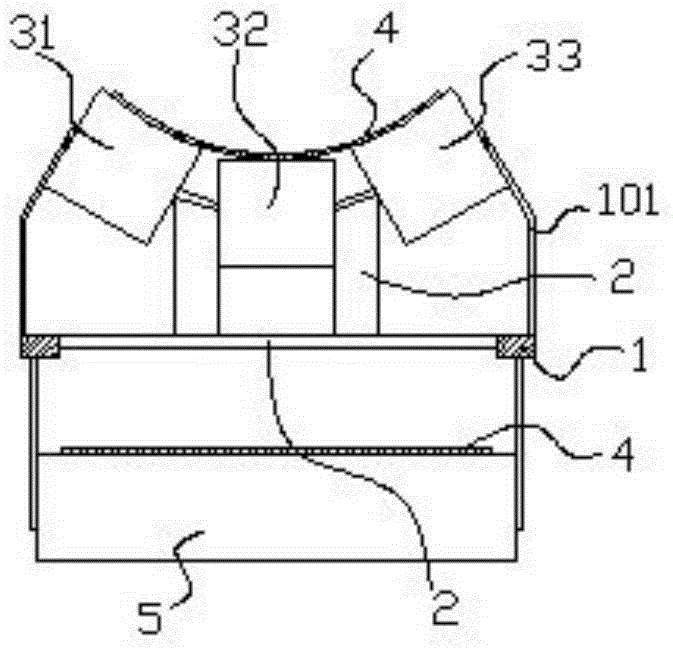

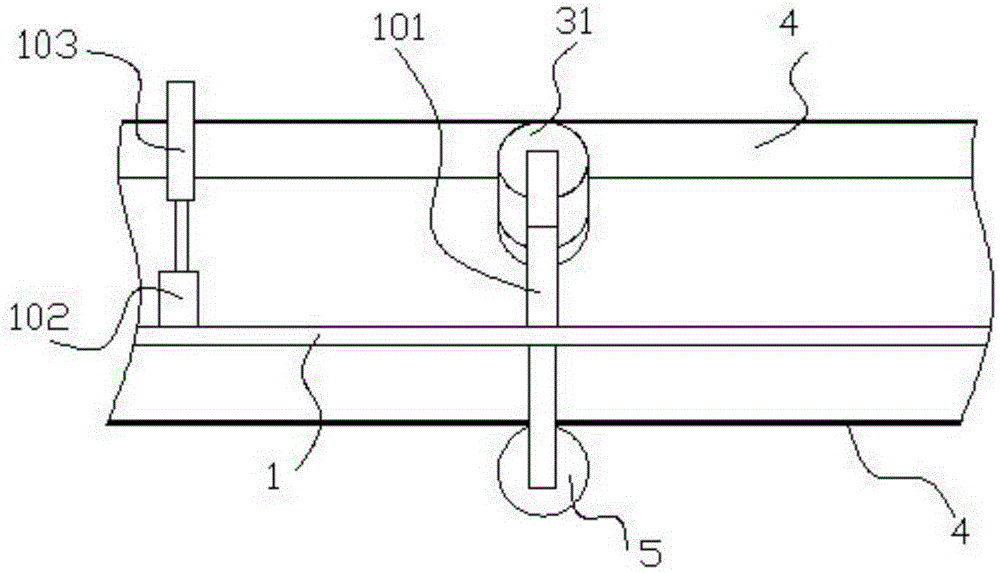

[0029] Such as Figure 1-Figure 4 As shown, the specific structure of the present invention is: a kind of leakage-proof transportation device for primary grinding of lime kiln, which includes a conveyor belt 4, traction power and a support 1, a vertical frame 2 is arranged above the support 1, and a vertical The upper layer roller 3 is fixed on the frame 2, and the upper layer roller 3 has multiple and is arranged in a concave arc shape; the lower layer roller 5 is arranged under the support 1, and the upper layer roller 3 and the upper layer roller 5 are covered. There is a conveyor belt 4; both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com