Method for continuously extracting durene from MTG heavy petrol

A technology of durene and heavy gasoline, applied in crystallization purification/separation, distillation purification/separation, organic chemistry, etc., can solve the problems of low product purity, complicated treatment process, high energy consumption, etc., and achieve high crystallization purification temperature, The effect of simple processing and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

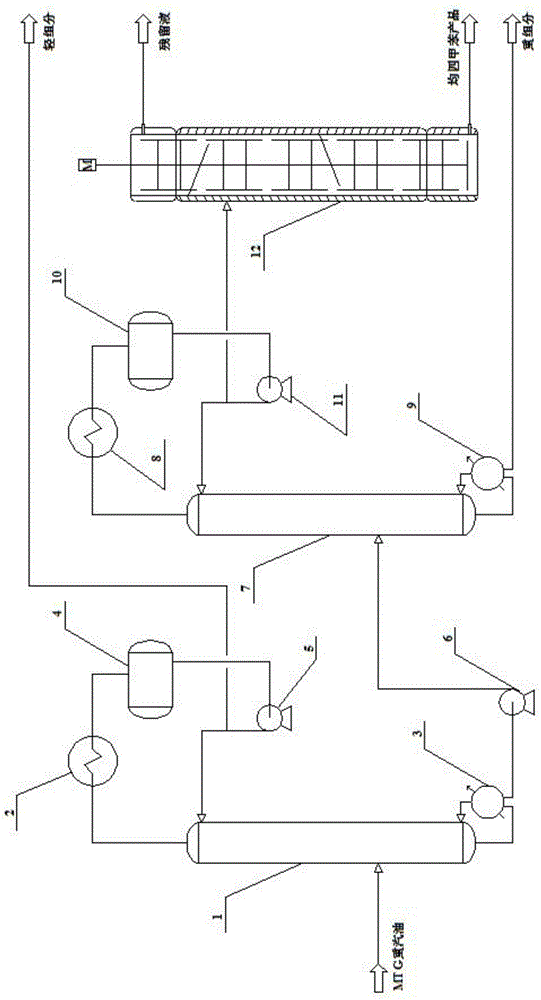

Embodiment 1

[0018] After the 1000kg / h durene raw material (40%) enters the light removal tower 1 for separation, 430kg / h of gasoline blending components are obtained at the top of the tower. After the tower liquid enters the weight-removing tower 7 for separation, the tower still gets 175kg / h of heavy oil, and the tower top component is rich in mesitylene. 11 Return a part of it to the weight-removing tower as reflux, and the other part goes through the crystallization tower 12 for crystallization and separation. Adjust the stirring speed of the crystallization tower to 20rpm, the purification section is provided with three inclined trays, the melting section at the bottom of the tower is heated by a circulating water bath, and the crystallization section at the top of the tower is condensed with cooling water. When the operation is stable, the temperature of the melting section is maintained at 81°C, and the temperature of the purification section is 63°C. After crystallization and sepa...

Embodiment 2

[0020] After the 1000kg / h durene raw material (50% content) enters the delightening tower 1 for separation, a 300kg / h gasoline blending component is obtained at the top of the tower. After the tower liquid enters the weight-removing tower 7 for separation, the tower still gets 152kg / h of heavy oil, and the tower top component is rich in mesitylene. 11 Return a part of it to the weight-removing tower as reflux, and the other part goes through the crystallization tower 12 for crystallization and separation. Adjust the stirring speed of the crystallization tower to 20rpm, the purification section is provided with three inclined trays, the melting section at the bottom of the tower is heated by a circulating water bath, and the crystallization section at the top of the tower is condensed with cooling water. When the operation is stable, the temperature of the melting section is maintained at 81°C, and the temperature of the purification section is 63°C. After crystallization and ...

Embodiment 3

[0022] After the 1000kg / h durene raw material (60% content) enters the light removal tower 1 for separation, 220kg / h of gasoline blending components are obtained at the top of the tower. After the tower liquid enters the weight-removing tower 7 for separation, the tower still gets 137kg / h of heavy oil, and the tower top component is rich in mesitylene. 11 Return a part of it to the weight-removing tower as reflux, and the other part goes through the crystallization tower 12 for crystallization and separation. Adjust the stirring speed of the crystallization tower to 20rpm, the purification section is provided with three inclined trays, the melting section at the bottom of the tower is heated by a circulating water bath, and the crystallization section at the top of the tower is condensed with cooling water. When the operation is stable, the temperature of the melting section is maintained at 81°C, and the temperature of the purification section is 63°C. After crystallization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com