Polypropylene stereo-tacticity conditioning agent and application thereof

A technology of stereoregularity and regulator, which is applied in the field of catalytic system components for changing the stereoregularity of polypropylene, can solve the problems of a large amount of external electron donors and a narrow adjustment range of the stereoregularity, and achieves a grade of Easy to switch and easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

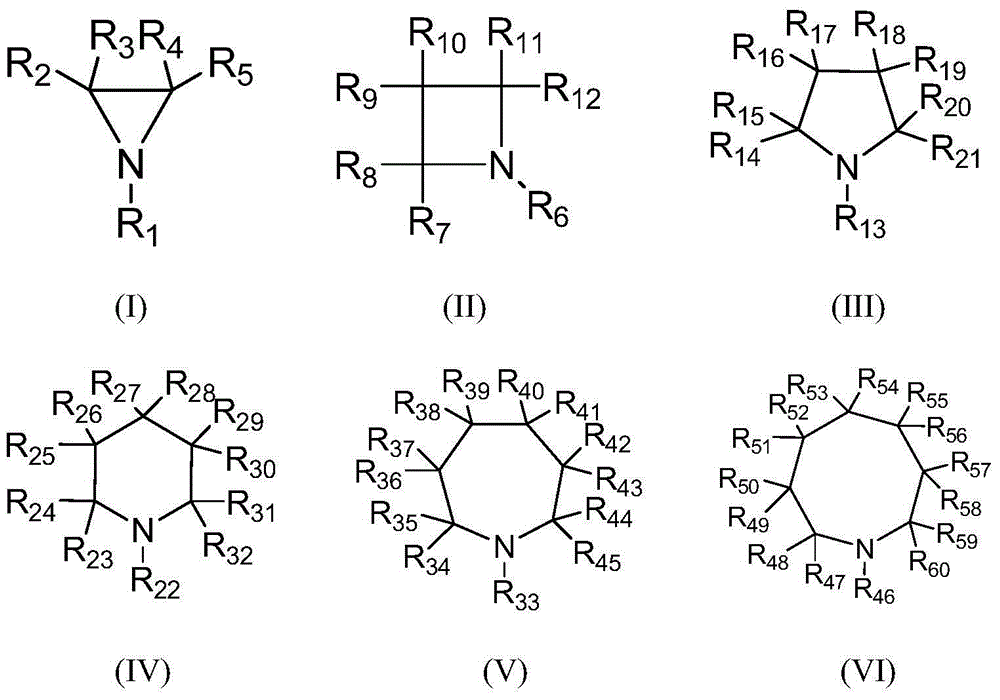

Method used

Image

Examples

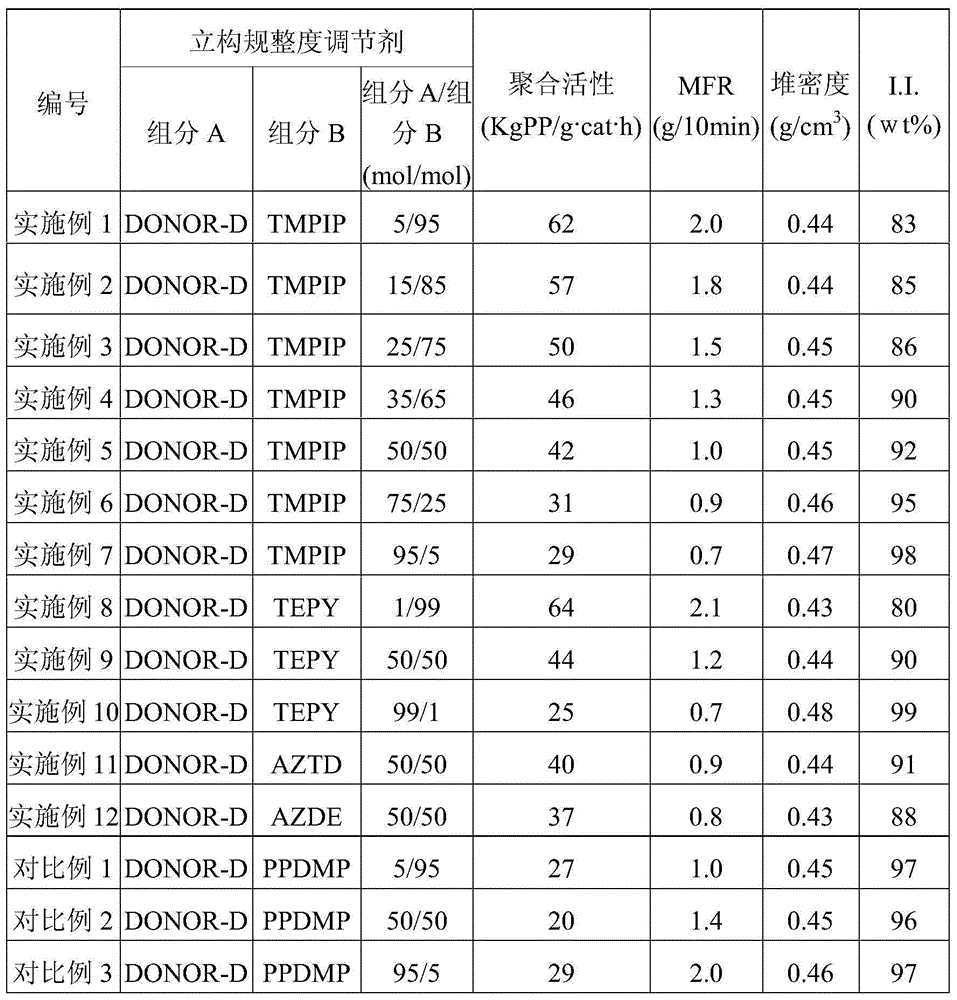

Embodiment 1

[0036] The polymerization reaction of propylene was carried out in a 5L polymerization tank reactor with magnetic stirring. First, the reactor was replaced three times with nitrogen, and 1.0mmol cocatalyst triethylaluminum, 0.2mmol tacticity regulator [2 Cyclopentyldimethoxysilane (DONOR-D) / 2,2,6,6-tetramethylpiperidine (TMPIP)=5 / 95 (mol / mol)] and 12-14mgBCK catalyst (Sinopec Catalyst Company Beijing Provided by Aoda Branch, the mass content of Ti element is 2.0%, and the mass content of Mg element is 18%. For the specific preparation method, refer to the patent document CN101993506B), carry out pre-complexation reaction at room temperature for two minutes in the catalyst feeding tube, and then add the catalyst mixed solution Into the reaction kettle, add 0.08MPa hydrogen (partial pressure in the reactor of the polymerization kettle), add 2.2L of propylene monomer into the 5L polymerization kettle, start stirring, heat up to 70±2°C, react for 1 hour, and end the reaction. Evac...

Embodiment 2

[0038] The catalyst used in embodiment 2, polymerization condition are identical with embodiment 1. The difference from Example 1 is that the ratio of component A (DONOR-D) and component B (TMPIP) in the tacticity modifier is adjusted to 15 / 85 (mol / mol), and the obtained polypropylene analysis result And the physical properties of the polypropylene are shown in Table 1.

Embodiment 3

[0040] The catalyst used in embodiment 3, polymerization condition are identical with embodiment 1. The difference from Example 1 is that the ratio of component A (DONOR-D) and component B (TMPIP) in the tacticity modifier is adjusted to 25 / 75 (mol / mol), and the obtained polypropylene analysis result And the physical properties of the polypropylene are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com