Mixed-flow type moving bed high-temperature gas filtering and purifying device and method

A filter purification and moving bed technology, which is applied in the direction of gas dust removal, selection of absorbent solid gas purification, etc., can solve the problems of large running resistance, small application range, waste water pollution, etc., and achieve the improvement of kiln temperature and remarkable energy saving effect , high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

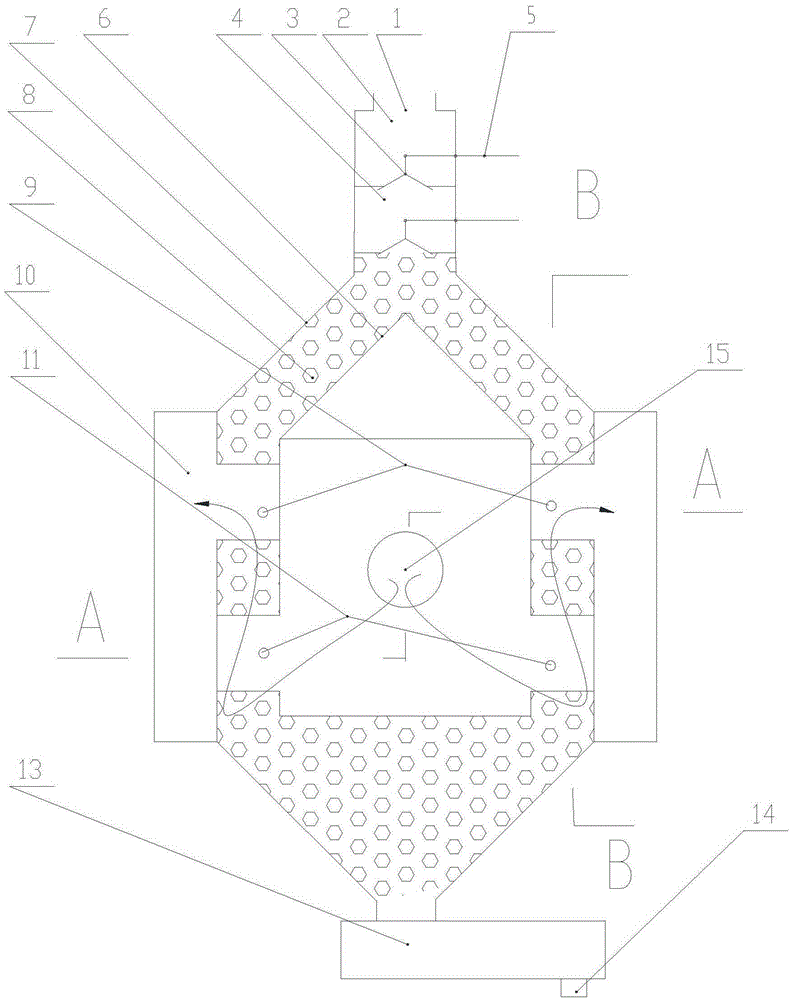

[0032] Such as Figure 1-Figure 7 As shown, a mixed-flow moving bed high-temperature gas filtration and purification device includes a main body inner shell 6 and a main body outer shell 7, wherein:

[0033] The interior of the main body inner shell 6 has a first chamber, the main body inner shell 6 is provided with a raw gas inlet 15, and the first chamber communicates with the raw gas delivery pipeline through the raw gas inlet 15;

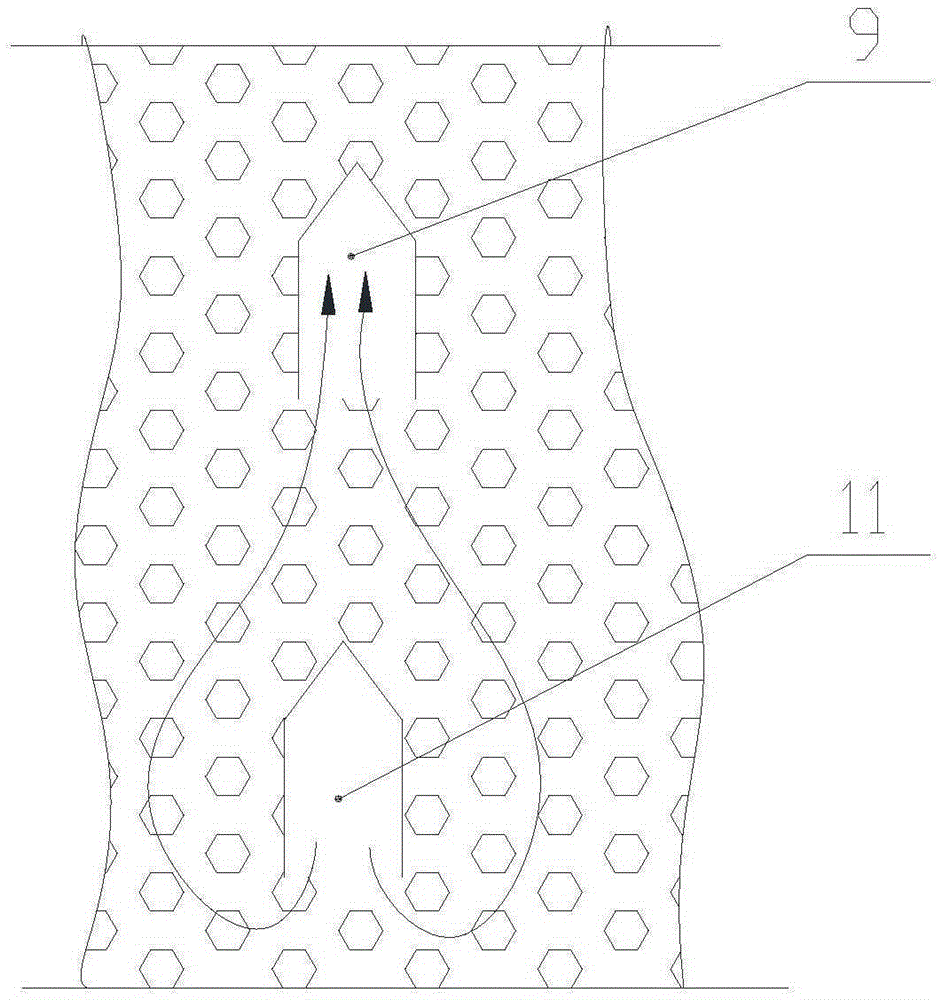

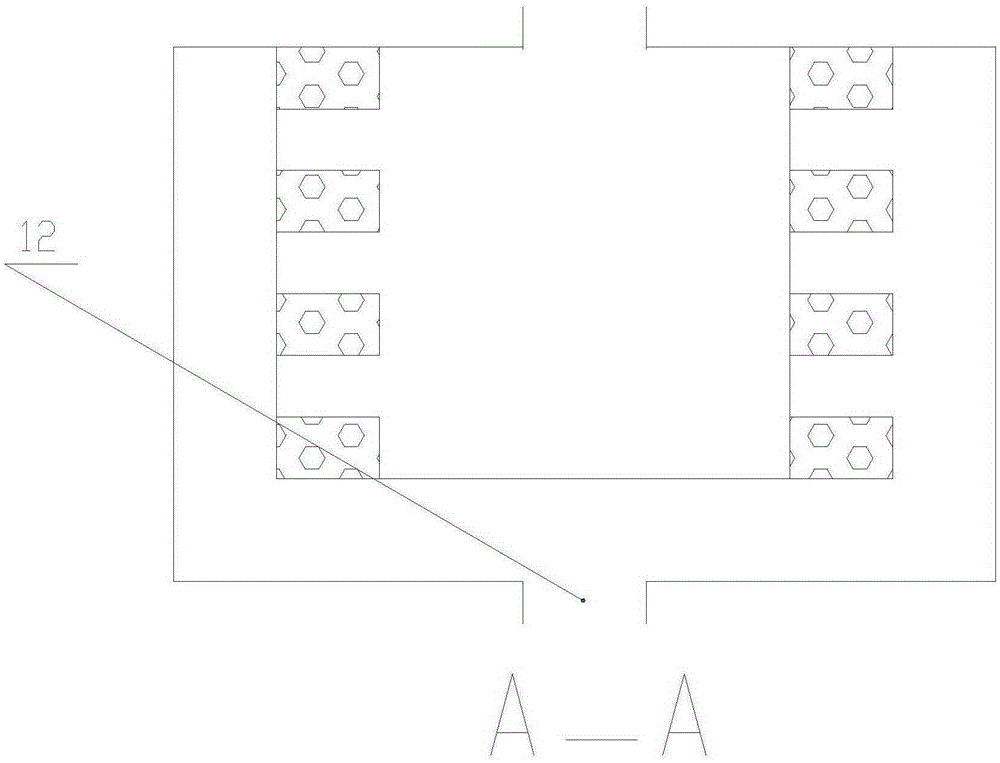

[0034] The main body shell 7 is sleeved on the outside of the main body inner shell 6 to form a main body inner cavity, which is filled with a filter material layer 8, and the first chamber and the main body inner cavity pass through the crude gas inlet provided on the main body inner shell 6 Connected to form evenly distributed crude gas channels 11, the main body shell 7 is provided with a purified gas outlet 12 at a position away from the crude gas inlet, and the main body inner cavity communicates with the purified gas pipeline through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com