Energy-saving type hydraulic station

A hydraulic station, energy-saving technology, applied in the direction of fluid pressure actuating devices, servo motors, servo motor components, etc., can solve the problems of large power consumption, unfavorable energy conservation and environmental protection, waste, etc., to improve conversion efficiency and reduce usage. , the effect of reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

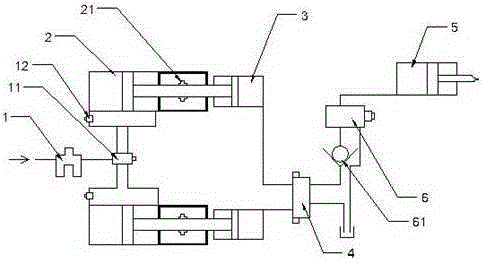

[0017] Embodiment 1 is basically as attached figure 1 Shown:

[0018] The energy-saving hydraulic station is installed on the driving end of the tooling fixture, including the hydraulic cylinder 5 connected with the tooling equipment, and also includes two oil cylinders 3, two cylinders 2, control valve 4, and reversing valve 6. The two cylinders 2 are connected with With the same air source device, the output rod of cylinder 2 is connected to the piston of cylinder 3, the oil circuit input end of oil cylinder 3 is connected to the oil tank through control valve 4, and the oil circuit output end of oil cylinder 3 is connected to control valve 4 and reversing valve 6 , the reversing valve 6 is connected with the hydraulic cylinder 5, and the hydraulic cylinder 5 completes the driving of a series of tooling equipment.

[0019] Both the reversing valve 6 and the control valve 4 are equipped with oil return pipes connected to the oil tank, and the oil pipe between the reversing v...

Embodiment 2

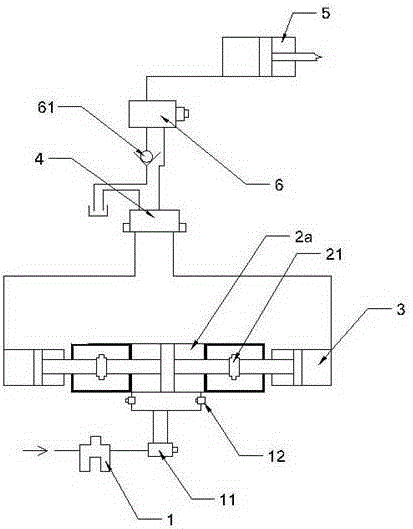

[0022] Embodiment 2 is basically as figure 2 Shown:

[0023] The difference from Example 1 is that the two cylinders 2 in Example 1 are replaced by a double-headed cylinder 2a, and the two output rods of the double-headed cylinder 2a are respectively connected to the piston of the oil cylinder 3, and two oil cylinders 3 and double-headed cylinders are used. The combination of the cylinders 2a is driven, and the oil cylinder 3 can be replaced for continuous driving when the oil cylinder 3 reaches a critical point, so that the hydraulic system is more stable. Limiting blocks 21 are respectively provided on the two output rods of the double-headed cylinder 2a, and the area of the limiting blocks 21 is larger than the area of the through hole passing through the two ends of the output rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com