Sludge drying method and dryer

A dryer and sludge technology, applied in separation methods, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as low fuel utilization rate and environmental pollution, achieve good heating effect, reduce Pollution, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

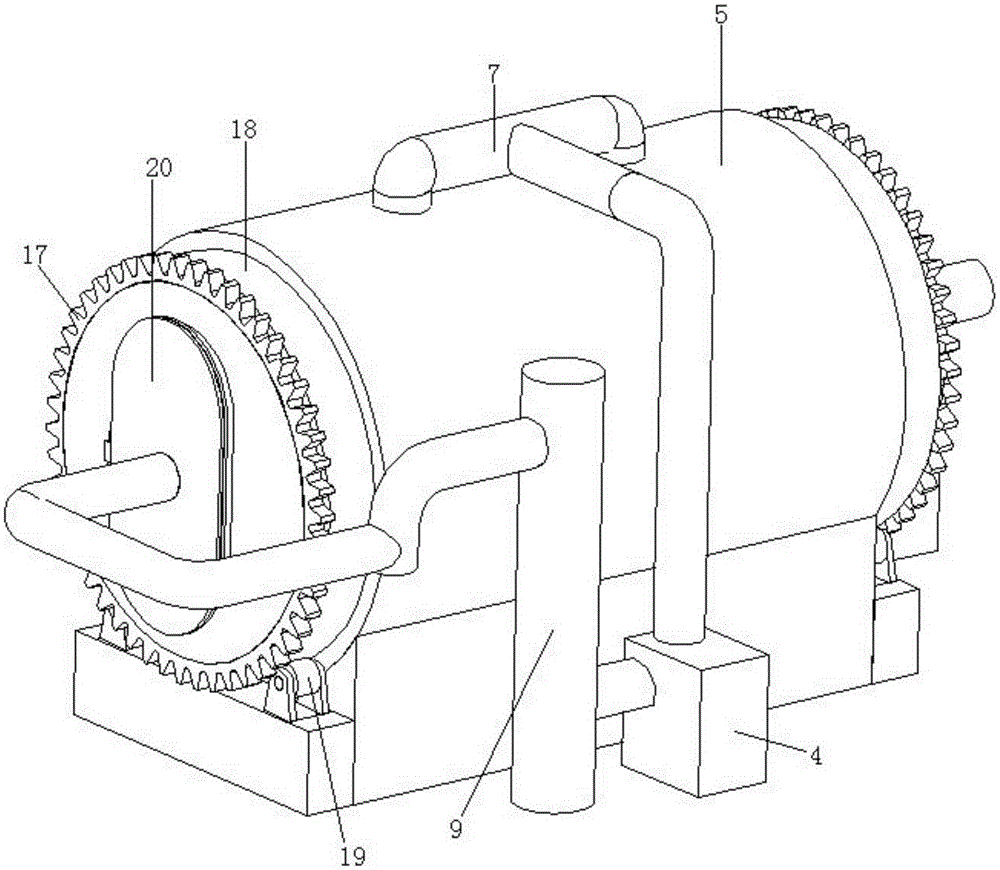

[0038] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

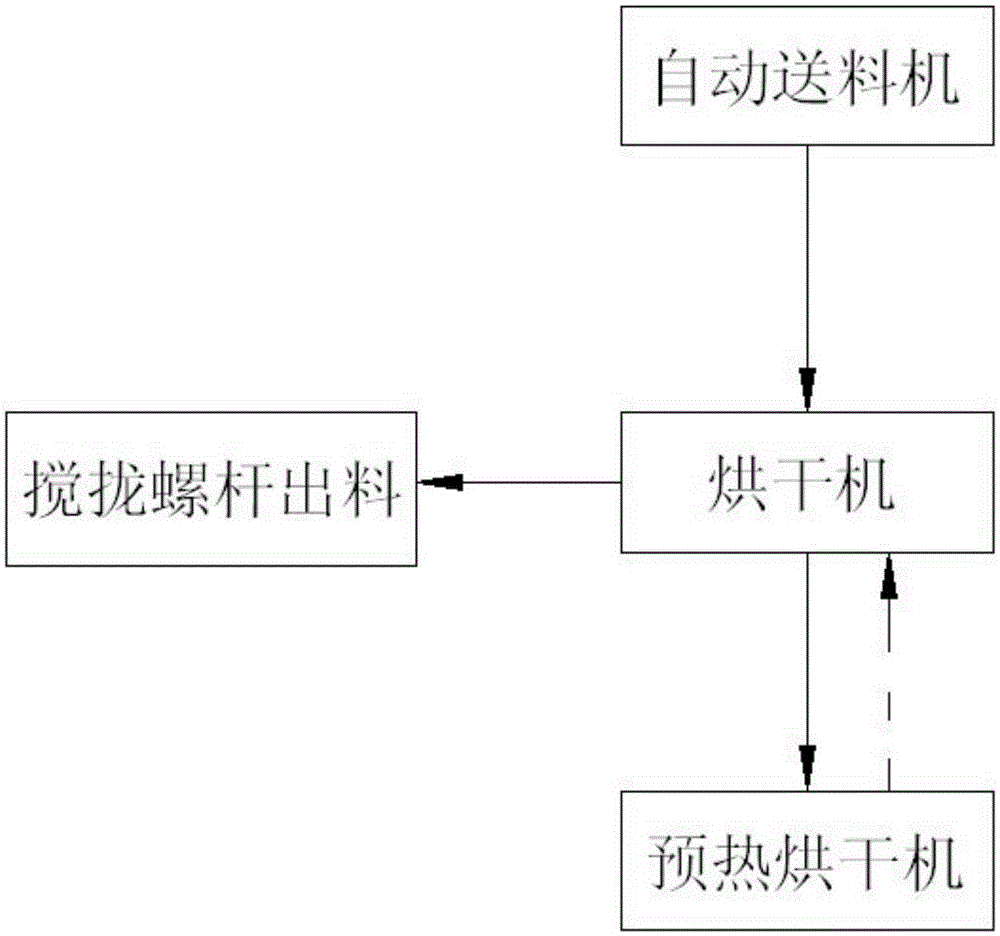

[0039] A method for drying sludge, the method comprising the following steps:

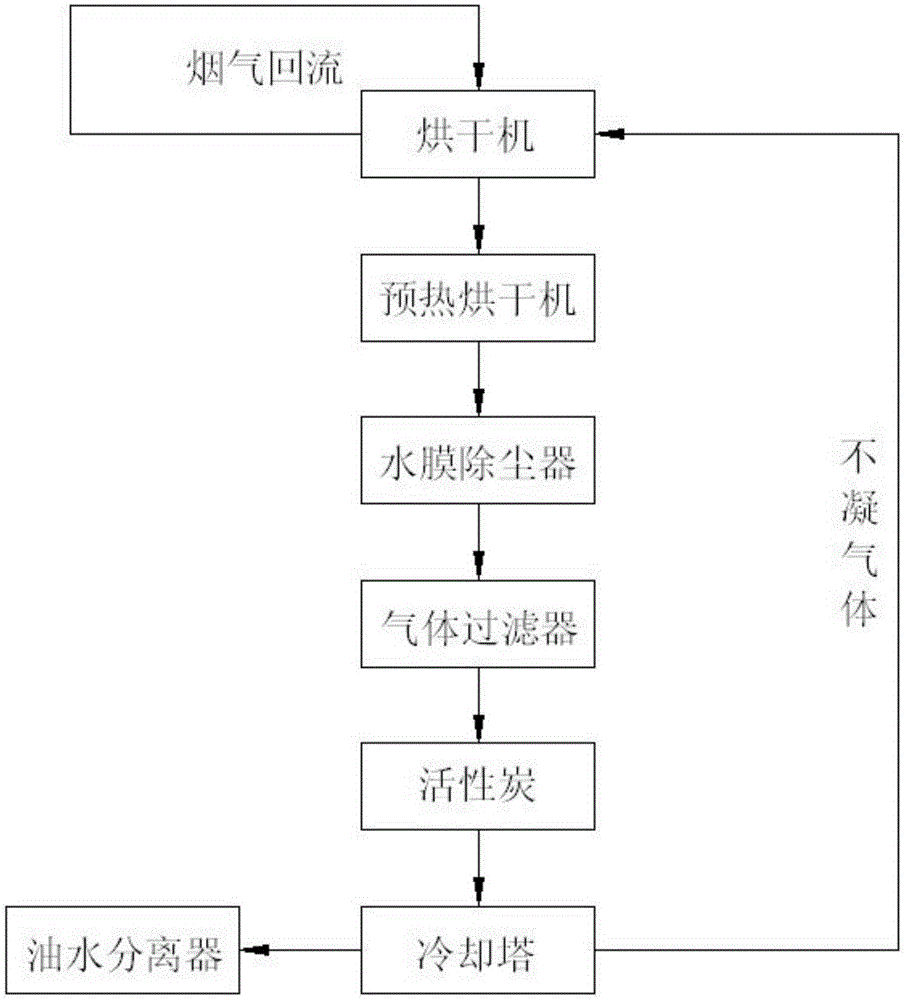

[0040] A: Drying: Transport the sludge to the drying cylinder 1 of the dryer, provide a heat source in the combustion hood 5 of the dryer to heat the outer wall of the drying cylinder 1, and generate heat and smoke through the combustion hood 5 The flue gas return pipe 7 is transported to the inside of the drying cylinder 1 to directly heat the sludge.

[0041] B: Desulfurization and dust removal: the flue gas in the drying cylinder 1 is connected to the water film dust collector 9 through the exhaust pipe, and desulfurization and dust removal are performed in the water film dust collector 9 .

[0042] C: Condensation: Condensate the gas after desulfurization and dust removal, and collect the condensate. Preferably, the gas after desulfurization and dust removal is cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com