Plasma Beam Chromium Plating Process of Piston Rod of Hydraulic Prop

A technology of hydraulic prop and plasma beam, which is applied in the field of surface treatment of hydraulic prop piston rod, can solve the problems of bubbling, bursting, peeling and inlaid stainless steel sleeves, etc., and achieves long service life, good resistance to coal particle impact, and fine structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

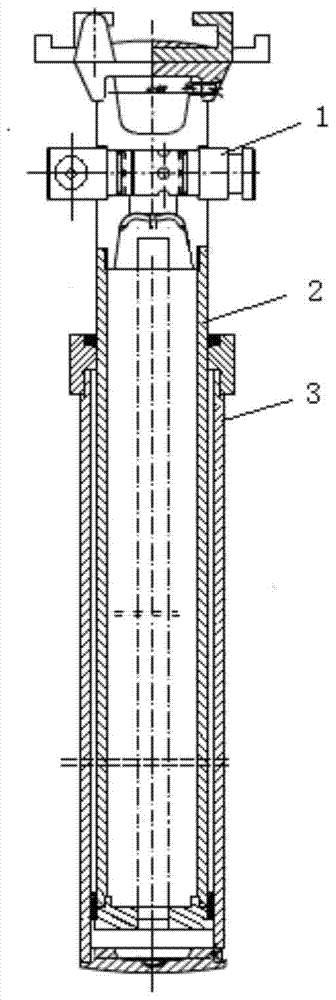

[0026] The present invention adopts the following steps to solve (with piston rod as an example)

[0027] Step 1, remove the incomplete chrome plating layer, pits and pits on the working surface of the piston rod on the lathe, so that the surface of the workpiece is free of defects (usually 2-3mm is removed by turning);

[0028] Step 2, surfacing the piston rod with gas shielded welding, the thickness of the surfacing layer is greater than the thickness removed by machining in step 1 (eg 3.5 mm).

[0029] Step 3, removing excess surfacing layer by car, so that the size of the piston rod is

[0030] Step 4, clean the surface with acetone or absolute alcohol;

[0031] Step 5, add 250ml of water glass to every 1kg of chromium alloy powder (particle size 75-150μm) to make a slurry, and stir evenly in a mixer (about 30 minutes). The composition of chromium alloy powder is: 0.1%C, 25%Ni, 8%Si, 0.7%B, 10%Fe, 56.20%Cr.

[0032] Step six, spray alloy powder with a thickness of 0...

example 2

[0036] When the present invention is applied to the manufacture of a hydraulic strut piston rod, the following steps are adopted (with piston rod as an example)

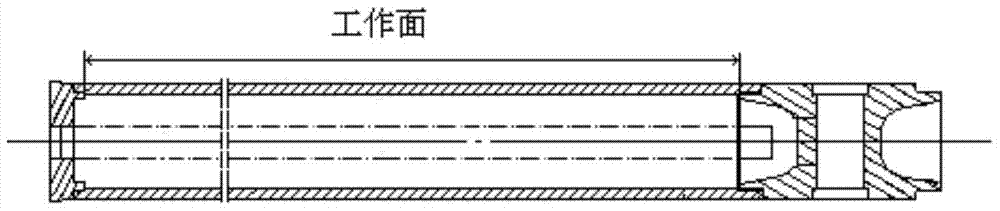

[0037] Step 1, process the hydraulic prop piston rod according to the drawing, the size of the processing part is

[0038] Step 2, clean the surface with acetone or absolute alcohol;

[0039] Step 3: Add 300ml of water glass to every 1kg of chromium alloy powder (with a particle size of 75-150μm), and stir in a mixer for 30 minutes to form a slurry. The composition of chromium alloy powder is: 0.05%C, 35%Ni, 5%Si, 1.0%B, 14%Fe, 44.95%Cr;

[0040] On surfaces requiring treatment,

[0041] Step 4, spray alloy powder with a thickness of 0.5mm on the working surface. Dry naturally for 24 hours, bake in an electric furnace at 60-80°C for 2 hours, then raise the temperature to 140-180°C for 4 hours.

[0042] Step 5, install the piston on the plasma processing machine, and perform plasma beam chrome plating-plasma a...

example 3

[0045] The present invention adopts the following steps to solve (with piston rod as an example)

[0046] Step 1, remove the incomplete chrome plating layer, pitting and pits on the working surface of the piston rod on the lathe, so that the surface of the workpiece is free of defects;

[0047] Step 2, surfacing the piston rod with gas shielded welding, the thickness of the surfacing layer is greater than the thickness removed by machining in step 1.

[0048] Step 3, removing excess surfacing layer by car, so that the size of the piston rod is

[0049] Step 4, clean the surface with acetone or absolute alcohol;

[0050] Step 5: Add 380ml of water glass to every 1kg of chromium alloy powder (particle size 75-150μm) to make a slurry, and stir in a mixer for 30 minutes to make it uniform. The composition of chromium alloy powder is: 0.08%C, 30%Ni, 6.5%Si, 0.5%B, 15%Fe, 47.92%Cr;

[0051] Step six, spray alloy powder with a thickness of 0.5mm on the working surface. Dry na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com