Methane gas thin-layer medium electrochemical biosensor and preparing method thereof

A biosensor, methane gas technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of high cost, complicated operation and zeroing process, poor quantitative accuracy of methane detector, etc., to achieve thin and uniform diameter , Improve the detection selectivity and sensitivity, and the effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

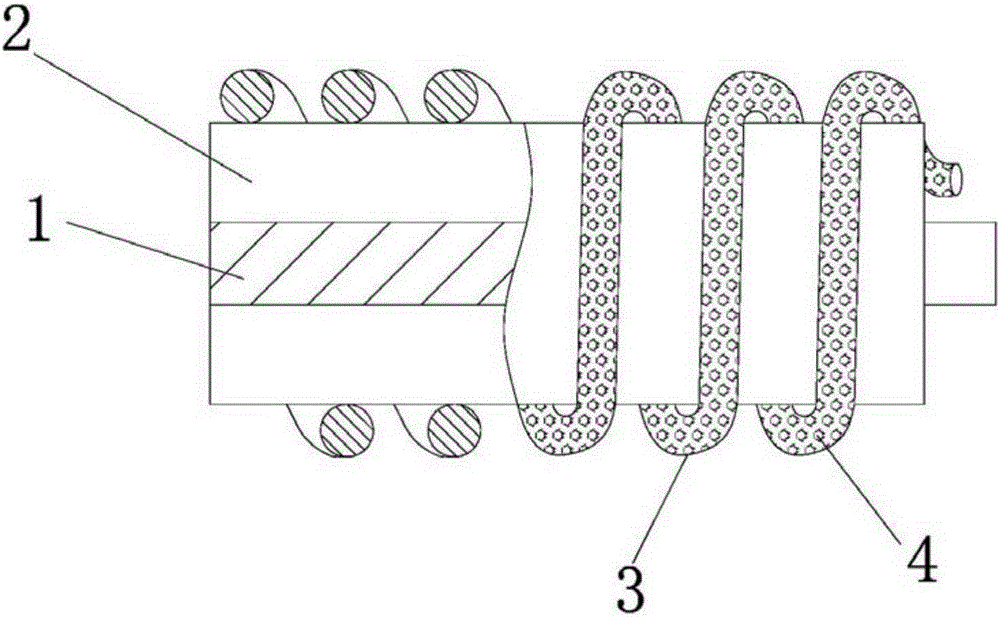

[0048] Methane gas thin layer dielectric electrochemical biosensor of the present invention, refer to figure 1 , including the counter electrode 1, one end of the counter electrode 1 is reserved for connection to the electrochemical workstation when detecting methane, the rest is wrapped with electrolytic paper 2, and the exterior of the electrolytic paper 2 is wrapped with carbon fiber monofilament 3, wherein the carbon fiber monofilament 3 One end is suspended in the air for connection to an electrochemical workstation when detecting methane, and methane-oxidizing bacteria 4 are attached to the carbon fiber monofilament 3 .

Embodiment 2

[0050] The preparation method of the methane gas thin-layer dielectric electrochemical biosensor in this embodiment includes the following steps:

[0051] (1) Pick the methanotrophic bacteria and inoculate them in the liquid culture medium, seal it, add methane gas according to 10% of the air volume, and feed the liquid culture medium with methane gas of the same volume as the liquid culture medium, at 28°C Cultivate for 23 days, then mix the bacterial culture solution and the liquid medium according to the volume ratio of 1:200, seal it, add methane gas according to 10% of the air volume, and pass into the liquid medium the same volume as the liquid medium Methane gas, cultivated at 28°C for 9 days;

[0052] (2) Soak a 10cm-long carbon fiber bundle in acetone for 15 minutes, remove the colloidal coating on the surface of the carbon fiber bundle, wash it with water, and dry it at 90°C; then place it in concentrated nitric acid for 10 minutes at room temperature and oxidize it,...

Embodiment 3

[0058] The preparation method of the methane gas thin-layer dielectric electrochemical biosensor in this embodiment includes the following steps:

[0059] (1) Pick methanotrophic bacteria strains and inoculate them in the liquid medium, seal it, add methane gas according to 10% of the volume of the air, and pass into the liquid medium the same volume of methane gas as the liquid medium, at 30°C Cultivate for 20 days, then mix the bacterial culture solution and the liquid medium according to the volume ratio of 1:200, seal it, add methane gas according to 10% of the air volume, and pass into the liquid medium the same volume as the liquid medium Methane gas, cultivated at 30°C for 7 days;

[0060] (2) Soak 10cm-long carbon fiber bundles in acetone for 5 minutes, remove the colloidal coating on the surface of the carbon fiber bundles, wash with water, and dry at 90°C; then oxidize in concentrated nitric acid for 20 minutes at room temperature, take it out, wash with water, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com