Method for preparing sulfur-rich polymer at room temperature through mechanochemically induced reverse vulcanization reaction

A sulfur-rich polymer, mechanochemical technology, applied in the field of material chemistry, can solve the problems of low boiling point small molecule comonomers, such as high reaction temperature and inability to react.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

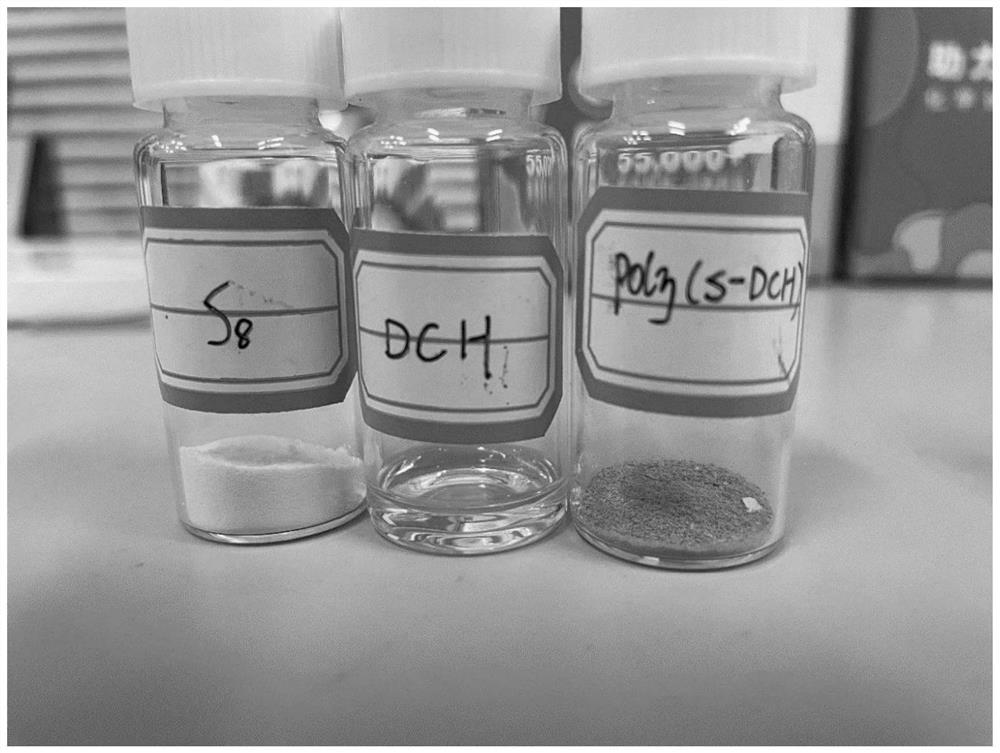

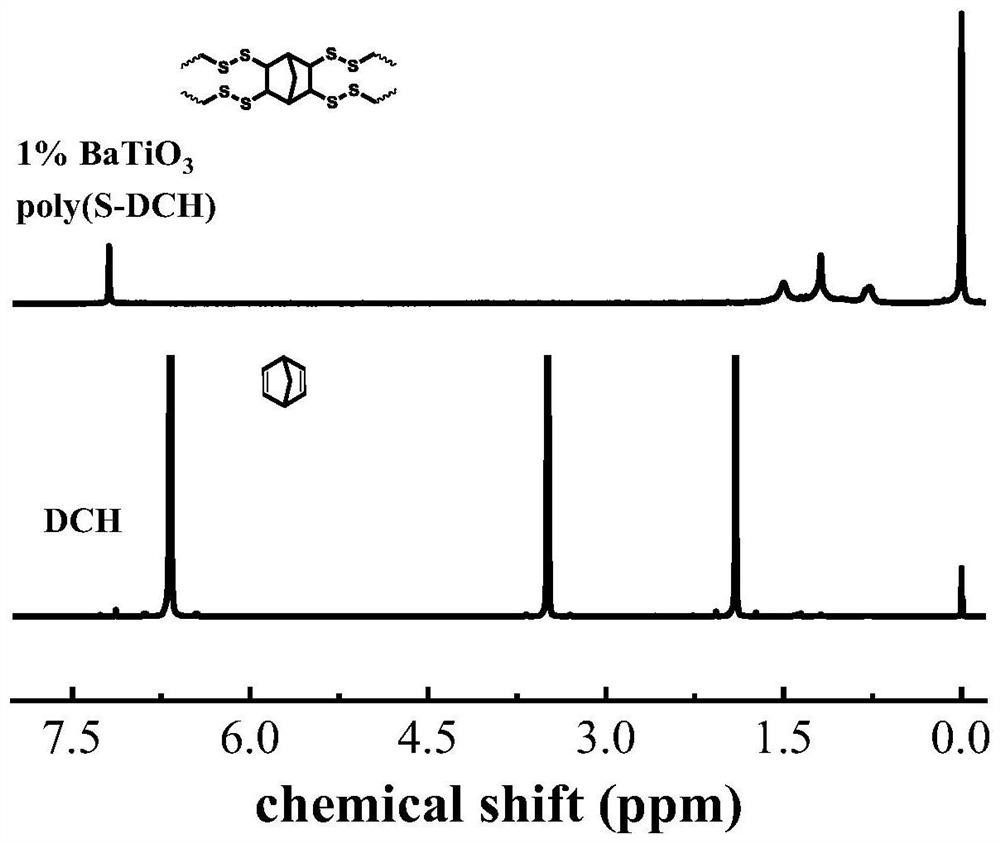

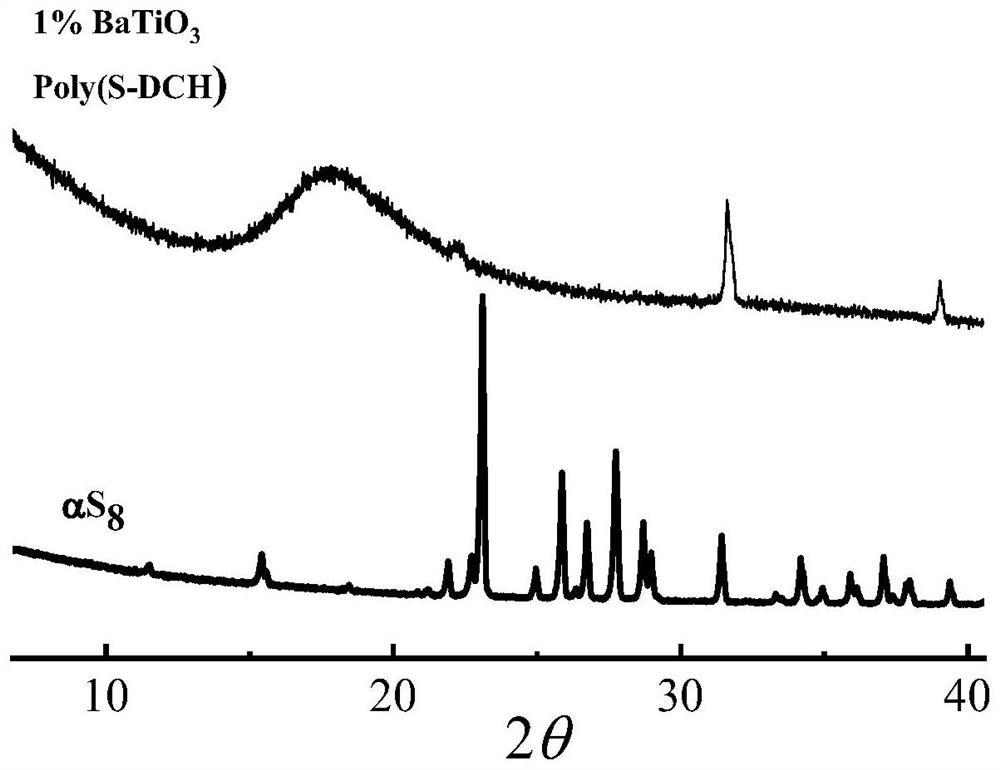

Embodiment 1

[0027] (1) Weigh 2.5g of sulfur elemental powder, 2.5g of dicycloheptadiene and 50.0mg of barium titanate in a 50ml cylinder of a vertical planetary ball mill, and react at room temperature for 6 hours at a speed of 300r / min. After the reaction is completed, , taken out with a spatula to obtain a sulfur-rich polymer. Characterized by XRD, the conversion rate of sulfur element is about 100%, and the hydrogen sulfide gas generation is less than 20ppm.

Embodiment 2

[0029] (2) Weigh 2.5g of sulfur elemental powder, 2.5g of 1,3-divinylbenzene and 50.0mg of barium titanate into a 50ml cylinder of a vertical planetary ball mill, and react at room temperature for 6 hours at a rotational speed of 300r / min. After the end, take out with a spatula to obtain the sulfur-rich polymer. Characterized by XRD, the conversion rate of sulfur element is about 100%, and the hydrogen sulfide gas generation is less than 20ppm.

Embodiment 3

[0031] (3) Weigh 2.5g of sulfur elemental powder, 2.5g of squalene and 50.0mg of barium titanate in a 50ml cylinder of a vertical planetary ball mill, and react at room temperature for 6 hours at a speed of 300r / min. After the reaction is completed, use The scraper was taken out to obtain the sulfur-rich polymer. Characterized by XRD, the conversion rate of sulfur element is about 100%, and the hydrogen sulfide gas generation is less than 20ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com