Preparation method of flexible semiconductor device

A semiconductor and inorganic semiconductor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low yield and high production cost of flexible semiconductor devices, achieve important application value, and achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

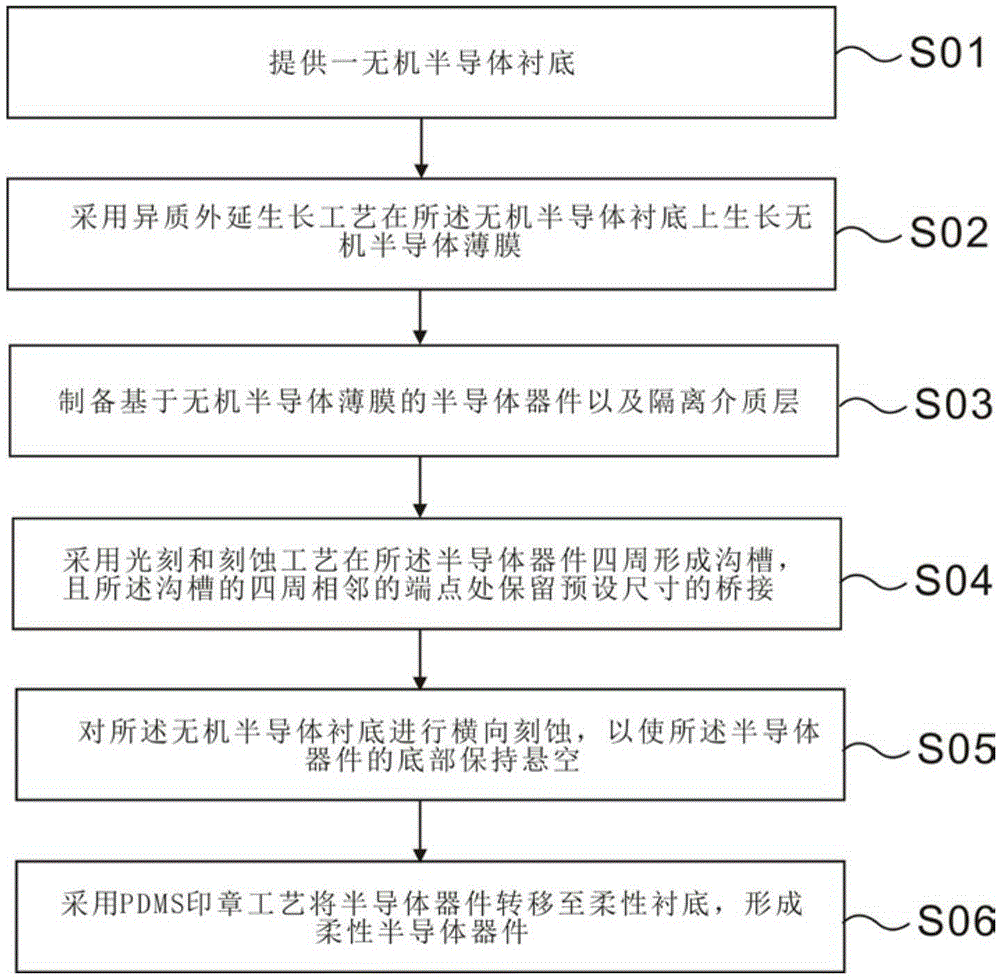

[0037] Such as figure 1 As shown, the present invention provides a method for manufacturing a flexible semiconductor device, including the following steps:

[0038] In step S01, an inorganic semiconductor substrate 100 is provided.

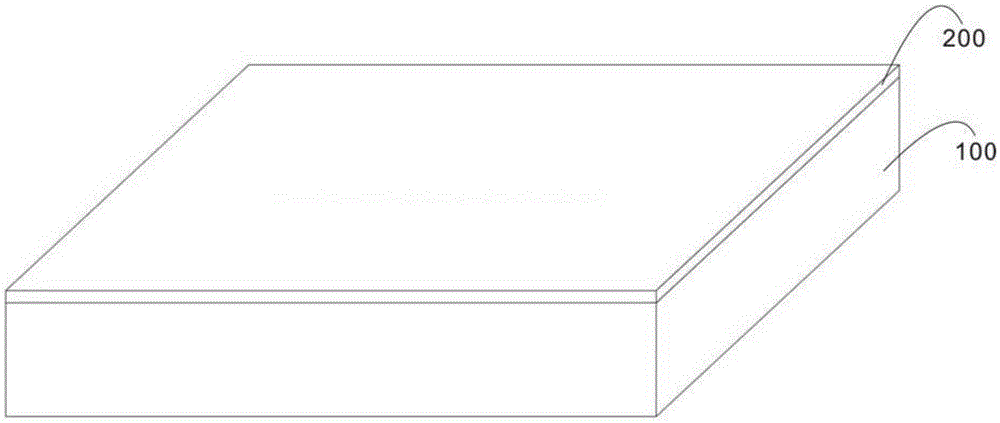

[0039] See Figure 2a In the present invention, the inorganic semiconductor substrate 100 can be used in an epitaxial growth process. The inorganic semiconductor substrate 100 is preferably a silicon substrate, a germanium substrate, a gallium arsenide substrate, a gallium nitride substrate or a III-V semiconductor substrate One of them. In this embodiment, the crystal orientation of the inorganic semiconductor substrate 100 is Silicon substrate.

[0040] In step S02, an inorganic semiconductor thin film 200 is grown on the inorganic semiconductor substrate 100 using a heteroepitaxial growth process.

[0041] Please keep reading Figure 2a In the present invention, the inorganic semiconductor thin film 200 can be selected from any heterogeneous semicond...

Embodiment 2

[0055] In order to make the lateral etching process in the present invention easier to implement, the present invention also provides a method for manufacturing a flexible semiconductor device, which specifically includes the following steps:

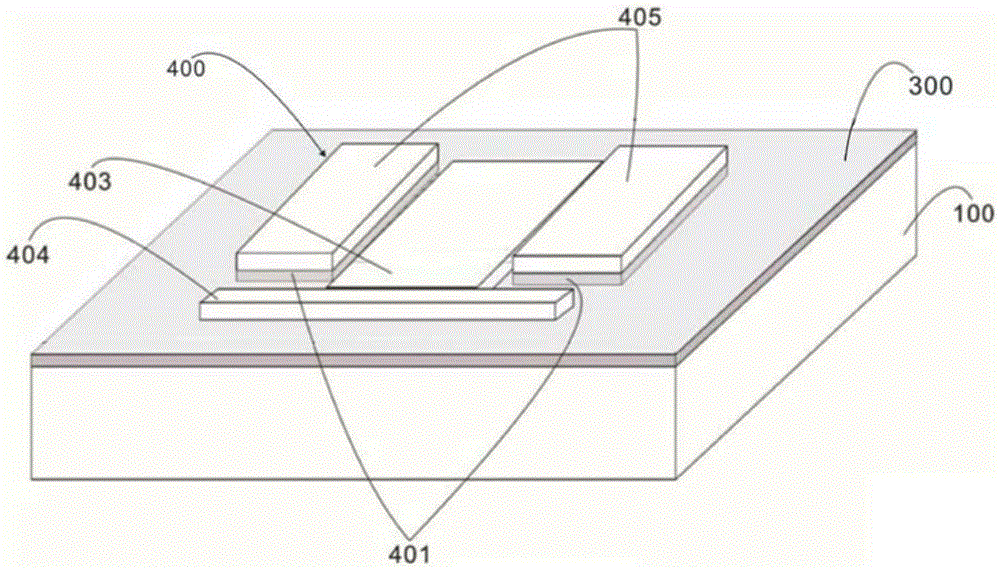

[0056] First, an inorganic semiconductor substrate 100 is provided, an isolation dielectric layer 300 is deposited on the inorganic semiconductor substrate 100, and the region to be prepared of the semiconductor device 400 is defined by photolithography and etching processes; then, a heteroepitaxial growth process is used in the semiconductor In the region to be prepared, an intermediate semiconductor layer (not shown in the figure) and an inorganic semiconductor thin film 200 are sequentially grown; next, a semiconductor device 400 based on the inorganic semiconductor thin film 200 is prepared; and then, photolithography and etching processes are used in the semiconductor device 400 A trench 500 is formed all around, and a bridge of a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com