Method for preparing titanium dioxide and perovskite plane heterojunction solar cell at low temperature

A technology of titanium dioxide and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of perovskite solar cell development limitations, affecting substrate selection, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

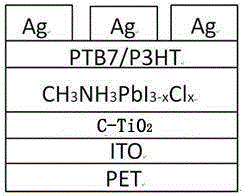

[0017] Below in conjunction with embodiment technical scheme of the present invention is described in detail, concrete steps are as follows:

[0018] The first step of cleaning the transparent conductive substrate PET / ITO:

[0019] The transparent conductive substrate is a flexible transparent conductive substrate PET / ITO. Clean the PET / ITO transparent conductive substrate with ultrasonic cleaning solution for 15 minutes, then continue to use a 1:1 mixed solution of alcohol and acetone for 15 minutes, and finally use 20% hydrogen peroxide solution for 10 minutes, and dry it with a nitrogen gun spare.

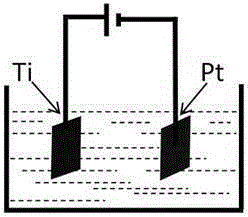

[0020] Preparation of the second step anodized titanium dioxide dense layer:

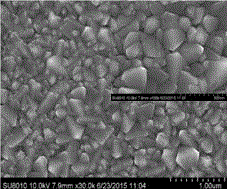

[0021] Put the above-mentioned standby PET / ITO substrate into the magnetron sputtering chamber, and first vacuumize the chamber to 10 -4 Below Pa, then argon gas is introduced to keep the pressure of the chamber at 0.3Pa, and a sputtering current of 0.2A is applied to obtain a metal translucent fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com