Power battery separator, preparation method thereof and power battery comprising same

A power battery and diaphragm technology, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., and can solve problems such as functional failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

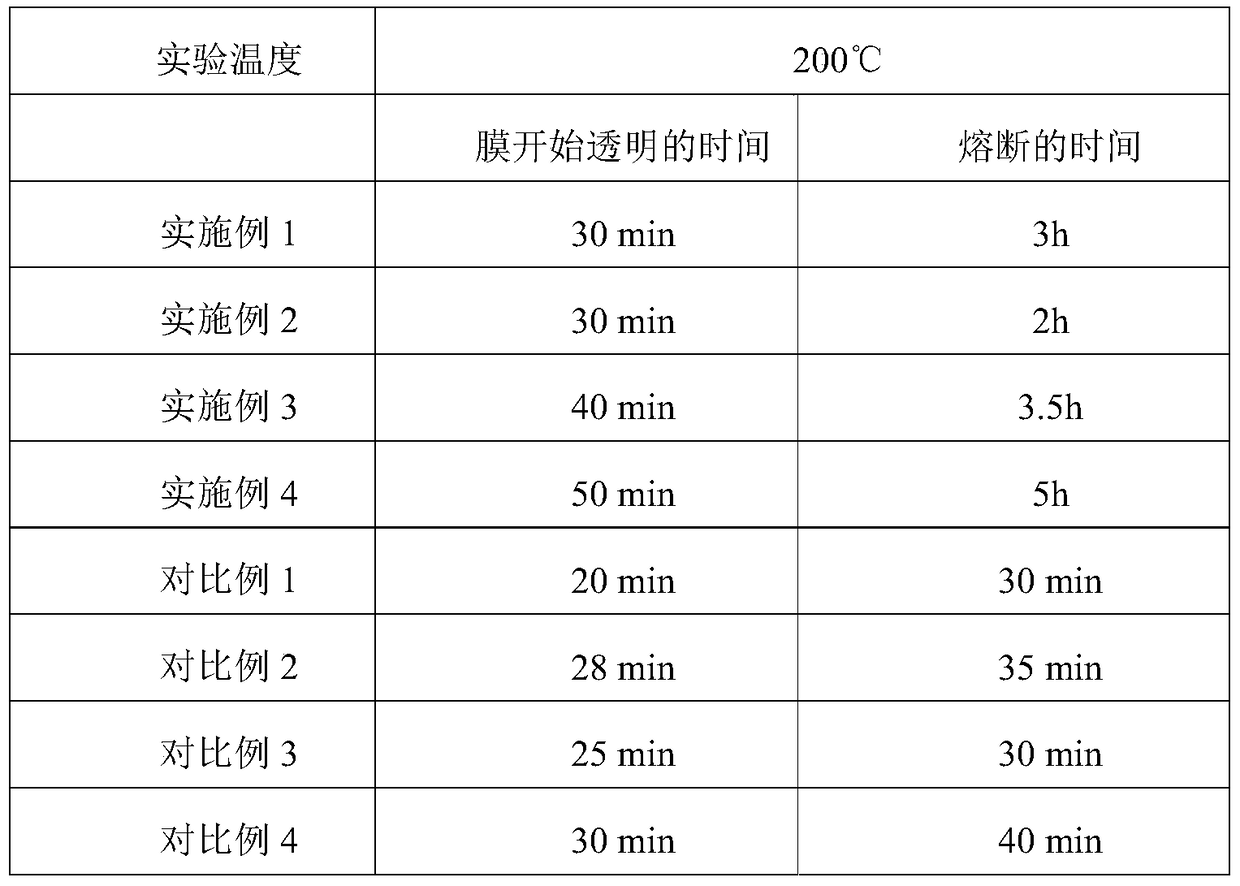

Examples

preparation example Construction

[0031] In addition, the present invention also provides a method for preparing a power battery diaphragm, which includes the following steps: preparing a Pickering emulsion containing ceramic particles, a phase change material, a synthetic monomer of a polymer, a crosslinking agent, and an initiator; making the Pickering emulsion The synthetic monomers in the process are polymerized, and after forming the polymer, the emulsion is dried to obtain phase change capsules; the phase change capsules are mixed with the binder used to form the base material to form a material liquid to be cured; the material liquid to be cured is coated on The first modified layer and / or the second modified layer are formed on the first surface and / or the second surface of the diaphragm main body after being cured, so as to obtain the power battery diaphragm.

[0032] In the above preparation method provided by the present invention, the Pickering emulsion containing ceramic particles, phase change mat...

Embodiment 1

[0044] Silica surface treatment: ultrasonically disperse 1 g of silica particles in 50 mL of ethanol, add 1 g of γ-aminopropyltriethoxysilane, and stir at room temperature for 5 h. The temperature rose to 80°C, and condensed and refluxed for 2h. Centrifuge, wash with ethanol, and dry for later use.

[0045] Disperse 1 g of surface-treated silica particles with an average particle diameter of 400 nm in 100 g of water, raise the temperature to 70° C., and use the mixed solution as the water phase.

[0046] 10g of paraffin wax with a melting point of 52°C, 3g of styrene, 1g of divinylbenzene, 0.5g of chlorinated paraffin, and 1g of azobisisobutyronitrile were mixed and heated to 70°C to form a molten oil phase.

[0047] After mixing the oil phase and the water phase, carry out high-speed stirring for 10 minutes, and the stirring speed is not lower than 5000rar / min. Get Pickering Lotion.

[0048] Add 1 g of SDS as an emulsifier to the emulsion, and polymerize at a constant temp...

Embodiment 2

[0051] Disperse 0.5 g of surface-treated silica particles with an average particle diameter of 400 nm (the treatment method is the same as in Example 1) in 100 g of water, and heat up to 70° C., and the mixed solution is used as the water phase.

[0052] Mix 6g of paraffin wax with a melting point of 52°C, 1g of styrene, 1g of divinylbenzene, 1g of chlorinated paraffin, and 0.06g of azobisisobutyronitrile, then heat up to 70°C to form a molten oil phase .

[0053] After mixing the oil phase and the water phase, carry out high-speed stirring for 10 minutes, and the stirring speed is not lower than 5000rar / min. Get Pickering Lotion.

[0054] Add 1g of SDS to the emulsion, and polymerize at a constant temperature of 70°C for 10 hours to obtain phase-change capsules.

[0055]After mixing 2g of phase-change capsules with 20g of binder PTFE, coat both sides of the PP / PE / PP three-layer composite separator, and after curing, a power battery separator is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com