Method and pulse forming apparatus for electrical discharge machining

A technology of spark processing and pulse, which is applied in electric processing equipment, metal processing equipment, circuits, etc., can solve problems such as inability to independently control process parameters, short pulses, and lack of arc protection, and achieve improved surface quality and fine contours , the effect of good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] In order to generate precise no-load voltage pulses of any shape and pulse duration, so-called discrete delay lines are ideally suitable.

[0094] Typical applications are sub-micron accurate alignment of micro-drilled holes for all types of nozzles.

[0095] Once the spark gap has been ignited, the invention makes it possible to deliver machining pulses of almost any short duration and almost any current amplitude without delay, depending on the nature and number of storage elements. The existing limiting physical phenomena have been discussed in the introduction. The invention makes it possible to overcome these phenomena to a large extent.

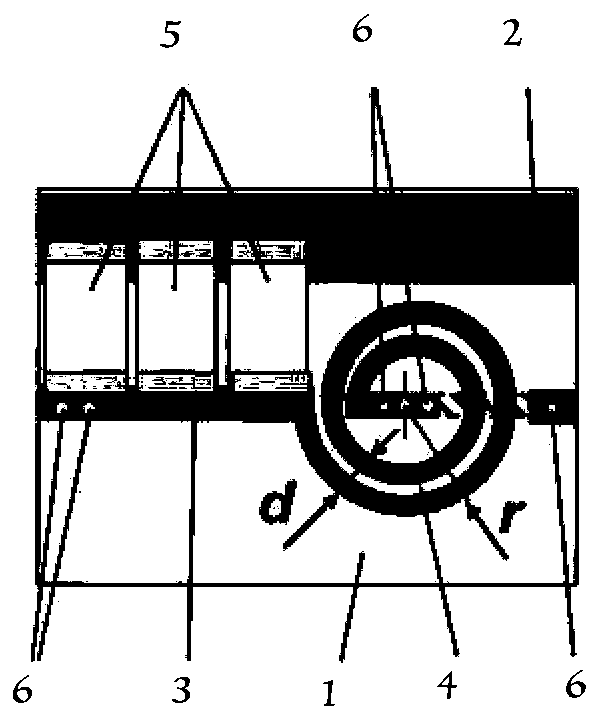

[0096] figure 1 A single storage element 4, 5 of a discrete delay line comprising a printed inductor 4 and, as an example, three capacitors 5 is illustrated. Inductor 4 is a planar air-core coil and its inductance can be determined approximately using the following equation:

[0097]

[0098] where L represents the induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com