A method for installing guide components of a frame-type hydraulic press dedicated to hot-press forging of high-speed rail components

A technology for guiding components and installation methods, applied in the direction of presses, manufacturing tools, etc., can solve the problems of high manufacturing cost, inconvenient later maintenance, bloated mechanism, etc., and achieve the effect of avoiding uncorrectable, reducing influence and facilitating welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

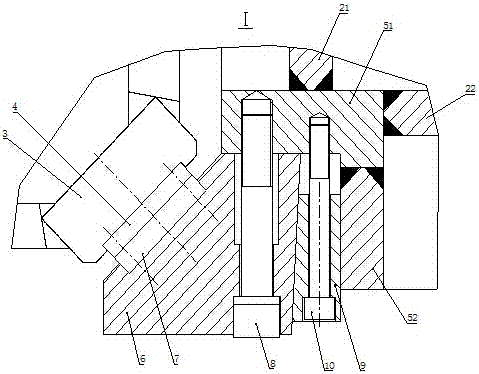

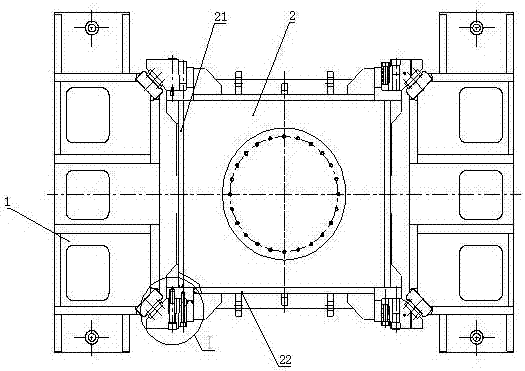

[0015] Such as Figure 1~3 As shown, step S1: install four guide rails 3 on the inner side of the column 1 of the frame type hydraulic machine, the angle between the guide surface of the guide rail 3 and the longitudinal panel 21 and the transverse panel 22 of the slider 2 is 45°, the guide rail 3 guide There is an inlay groove extending along the long axis direction of the guide rail 3 on the surface, and a wear-resistant sheet 4 on the side of the guide rail is fixed in the inlay groove.

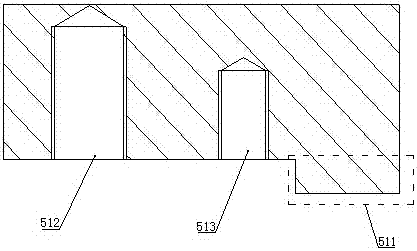

[0016] Step S2: Install an overall L-shaped adjustment seat at the junction of the end of the slider longitudinal panel 31 and the end of the slider transverse panel 22 at the four corners of the slider 2 to form a right-angle gap. The adjustment seat is divided into three steps Production, the specific operation is as follows: the first step is to process the welding groove at the end of the longitudinal panel 21 of the slider and the end of the transverse panel 22 of the slider; the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com