Dye continuous diazotization process

A technology of diazotization and dyes, which is applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of high cost in environmental protection, impossibility of cooling down very stably, and instability of adding liquid raw materials, etc., to achieve the best results Good, reduce the cost of environmental protection treatment, reduce the effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

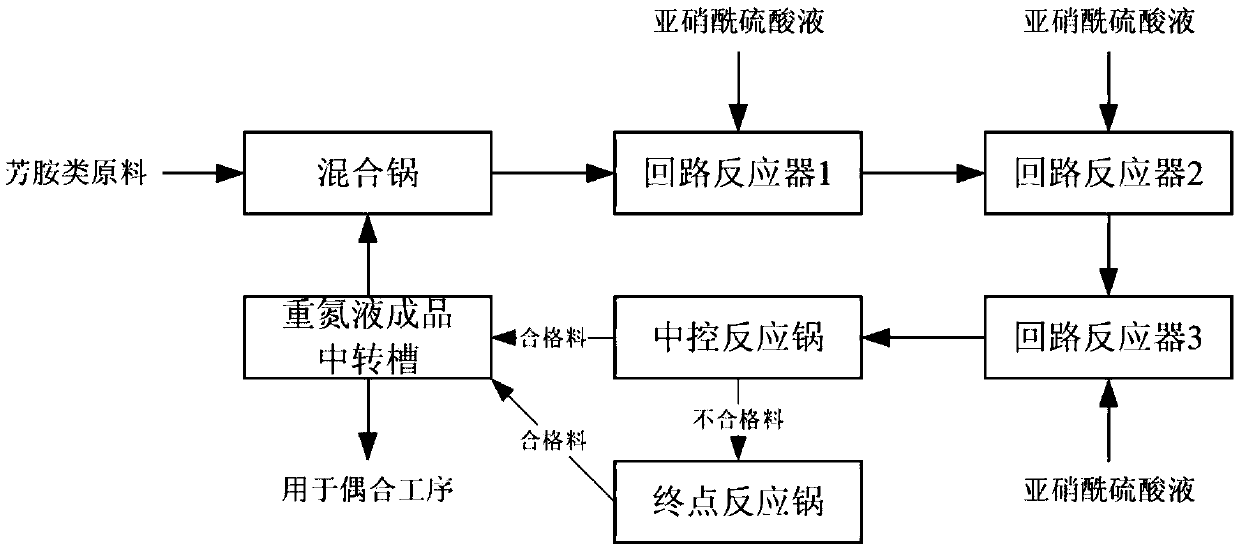

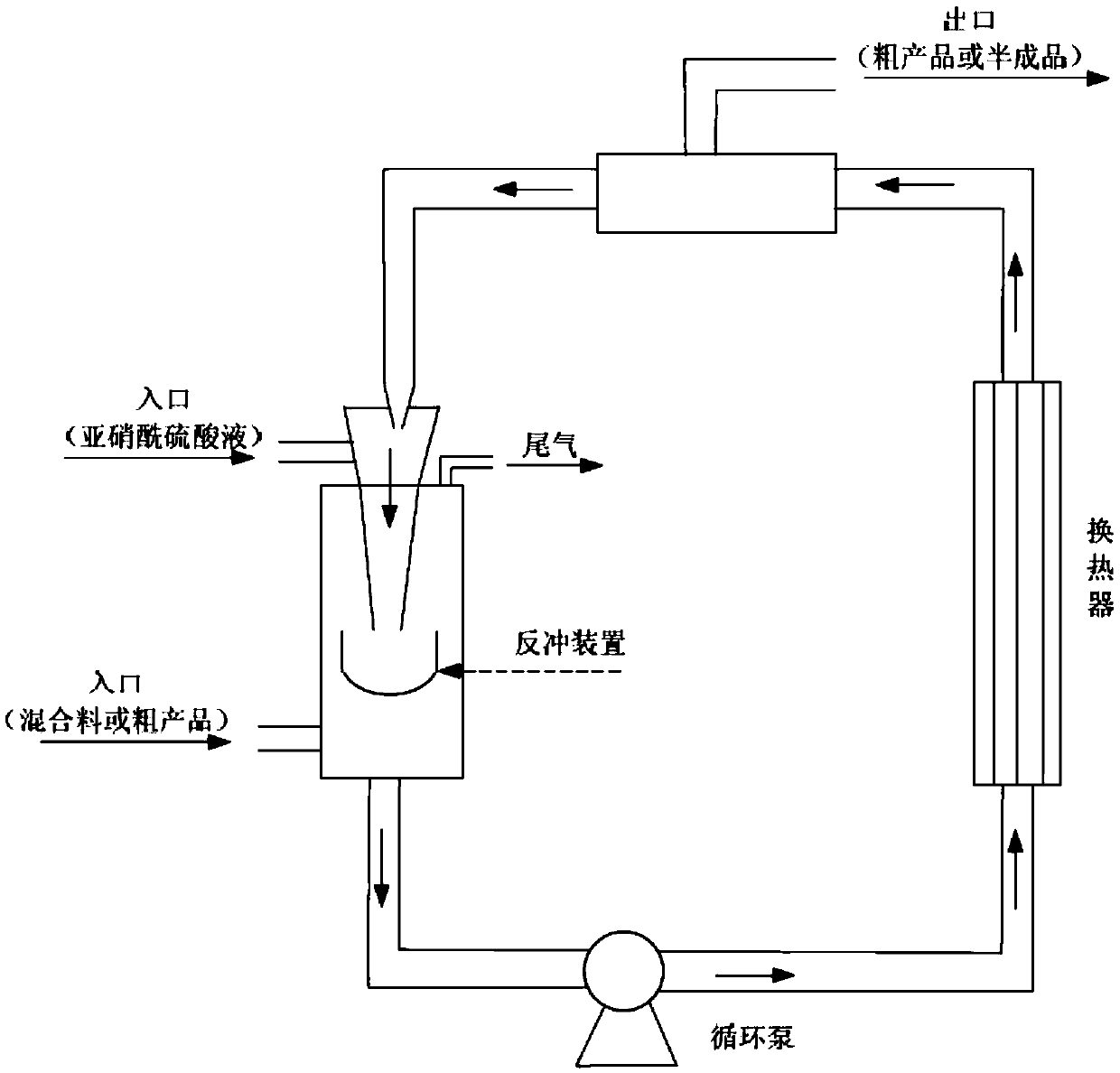

[0043] A 2-stage series continuous diazo loop reactor is adopted, with a single tank volume of 2000L, an external cooling jacket, and an external heat exchanger with a heat exchange area of 10M 2 ; 2-level parallel central control reaction pot; aromatic amines are 2,4-dinitro-6-bromoaniline, and the concentration of nitrosyl sulfuric acid solution (w / w) is 40%; the reaction residence time of the loop reactor is 3h.

[0044]Add the finished diazonium salt into the mixing pot, then put in powdered 2,4-dinitro-6-bromoaniline, and control the temperature at 15-25°C; control the diazonium salt: aromatic amine: nitrosyl sulfuric acid into The molar ratio of material is 2:1:1.02, and it is determined that the mixed feed rate in the primary loop reactor is 358.5kg / h (being diazonium salt 293kg / h, 2,4-dinitro-6-bromoaniline 65.5kg / h), the feed rate of nitrosyl sulfuric acid in the primary loop reactor is 48.6kg / h, and the control is realized through the combination of flow meter, re...

Embodiment 2

[0048] A 2-stage series continuous diazo loop reactor is adopted, with a volume of 3000L for a single tank, a cooling jacket outside, and a heat exchange area of 25M for the external heat exchanger. 2 ; 2-level parallel central control reaction pot; aromatic amines are 2,4-dinitro-6-bromoaniline, and the concentration of nitrosyl sulfuric acid solution (w / w) is 40%; the reaction residence time of the loop reactor is 3h.

[0049] Add the finished diazonium salt into the mixing pot, then put in powdered 2,4-dinitro-6-bromoaniline, and control the temperature at 15-25°C; control the diazonium salt: aromatic amine: nitrosyl sulfuric acid into The molar ratio of material is 2:1:1.02, and it is determined that the mixed feed rate in the primary loop reactor is 538kg / h (being diazonium salt 439kg / h, 2,4-dinitro-6-bromoaniline 99kg / h), the feed rate of nitrosylsulfuric acid in the primary loop reactor is 72kg / h, and the control is realized through the combination of flowmeter, reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com