Intercalation delay in-situ polymerization water shutoff gel for high-temperature oil reservoir

A technology of intercalation compounding and high-temperature oil, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor long-term thermal stability and short gelation time, and achieve good long-term stability and liquid preparation The effect of convenience and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

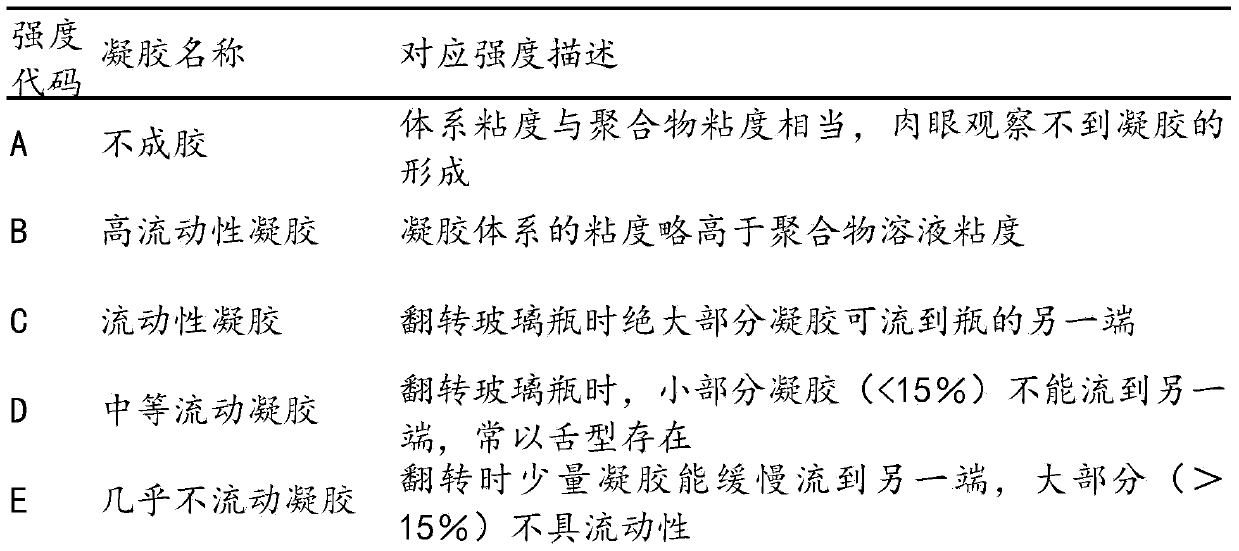

[0038]The total mass concentration of organic monomer acrylamide is 8%, the concentration of crosslinking agent (formaldehyde) is 2%, the main agent of intercalation (modified montmorillonite) is 6%, the concentration of gelation regulator (ethanol) is 0.8%, The concentration of the initiator (2,2'-azobis(2-methylpropionamidine) dihydrochloride) varies from 0.06% to 0.1%, and the rest is water. See Table 2 for the gelling conditions. The gelling time is between 4 and 10 hours, the final setting strength is grade I, and no syneresis occurs in 90 days.

[0039] Table 2 embodiment 1 gelation situation

[0040] Initiator concentration (%)

[0041] 0.06

Embodiment 2

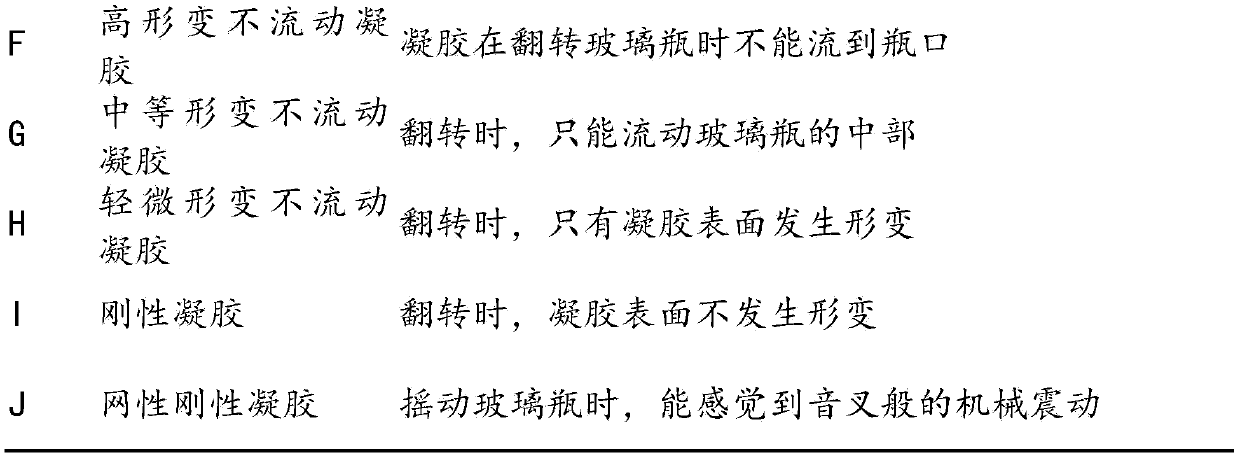

[0043] The total mass concentration of organic monomer acrylamide is 6%, the concentration of crosslinking agent (active phenolic resin) is 1%, the main agent of intercalation (kaolin) is 8%, the concentration of gelation regulator (methanol) is 1.5%, and the initiator (Ammonium persulfate) concentration ranges from 0.06% to 0.1%, and the rest is water. See Table 3 for the gelling conditions. The gelling time is between 16 and 24 hours, the final setting strength is grade I, and no syneresis occurs in 90 days.

[0044] Table 3 embodiment 2 gelation situation

[0045] Initiator concentration (%)

Embodiment 3

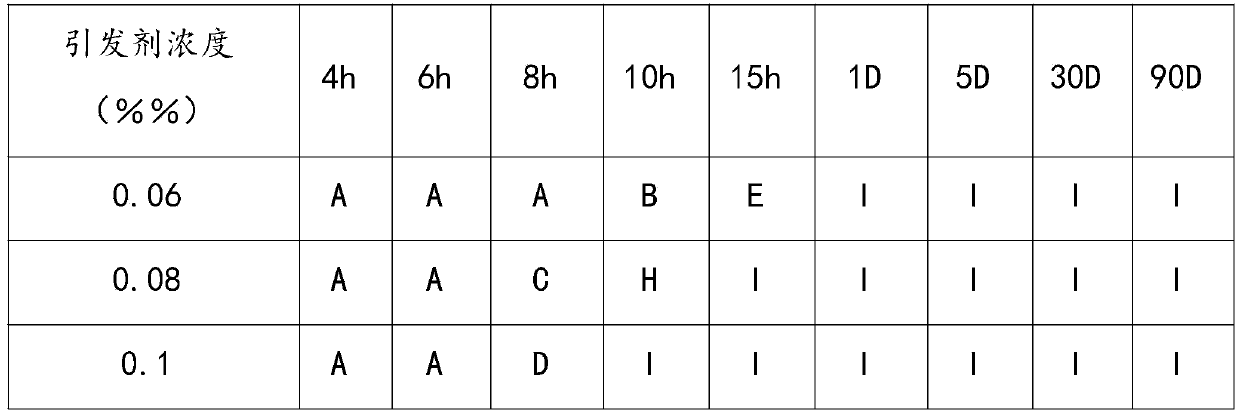

[0047] The total mass concentration of organic monomer acrylamide is 6%, the concentration of crosslinking agent (polyethyleneimine) is 1%, the main agent of intercalation (montmorillonite) is 8%, and the gelation regulator (methanol+ethylene glycol, The mass ratio (1:2) concentration is 2%, the initiator (ammonium persulfate) concentration ranges from 0.06% to 0.1%, and the rest is water. See Table 4 for the gelling conditions. The gelling time is between 20 and 30 hours, the final setting strength is grade I, and no syneresis occurs in 90 days.

[0048] Table 4 embodiment 3 gelation situation

[0049] Initiator concentration (%)

[0050] 0.1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com