Composite gel well killing rubber plug capable of rapidly gelatinizing and weighting at high temperature and preparation method thereof

A composite gel, high-temperature and fast technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of aggravation, high final setting strength, reservoir pollution, etc., and achieve a simple construction process and high final setting strength. , The effect of good glue forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The invention protects a preparation method of a high-temperature rapid gel-forming and weighted composite gel kill plug. The preparation method includes the following steps: firstly disperse the weighting agent of the formulated amount in water and stir, and after the weighting agent is fully dispersed, Add the formulated amount of toughening agent to it, after the toughener is uniformly dispersed, add the formulated amount of main agent, continue to stir for about 1-2 hours until the toughened agent is evenly distributed in the polymer solution, then add the formulated amount of crosslinking agent and a stabilizer, and stir evenly, that is, the preparation of the high-temperature rapid gel-forming and aggravated composite gel well-killing plug is completed.

[0064] In the present invention, after the main agent is dissolved in water, a covalent bond cross-linking reaction occurs with an organic cross-linking agent, finally forming a gel with high strength and good the...

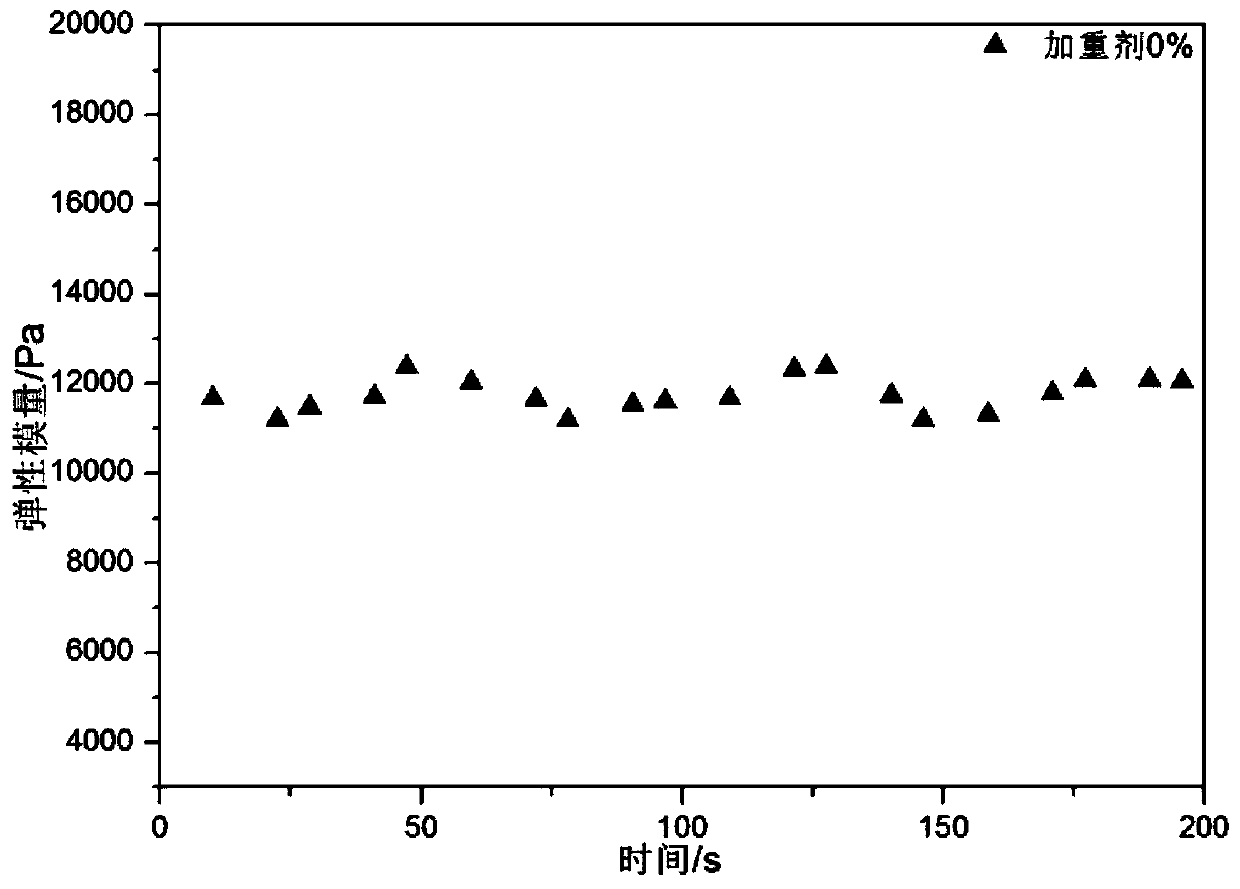

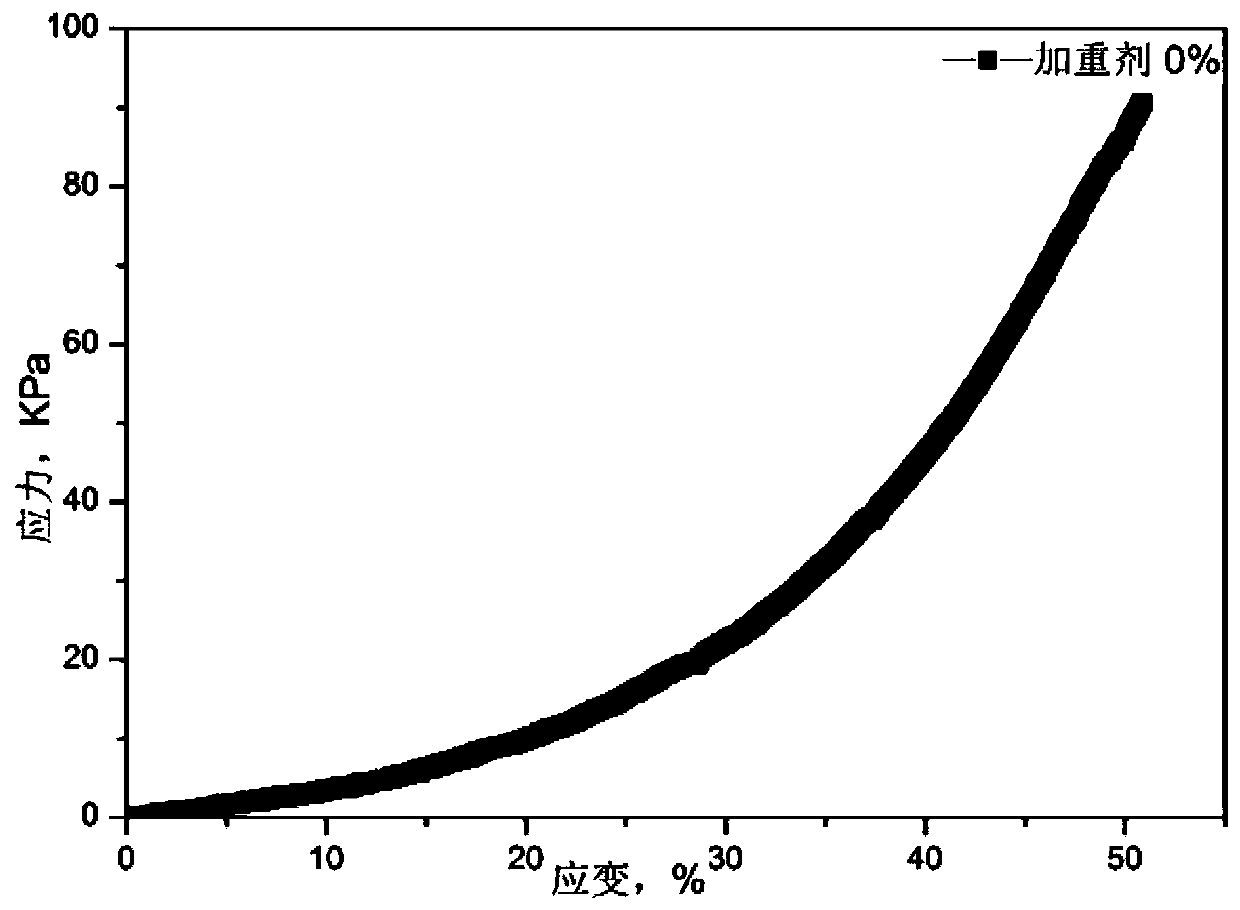

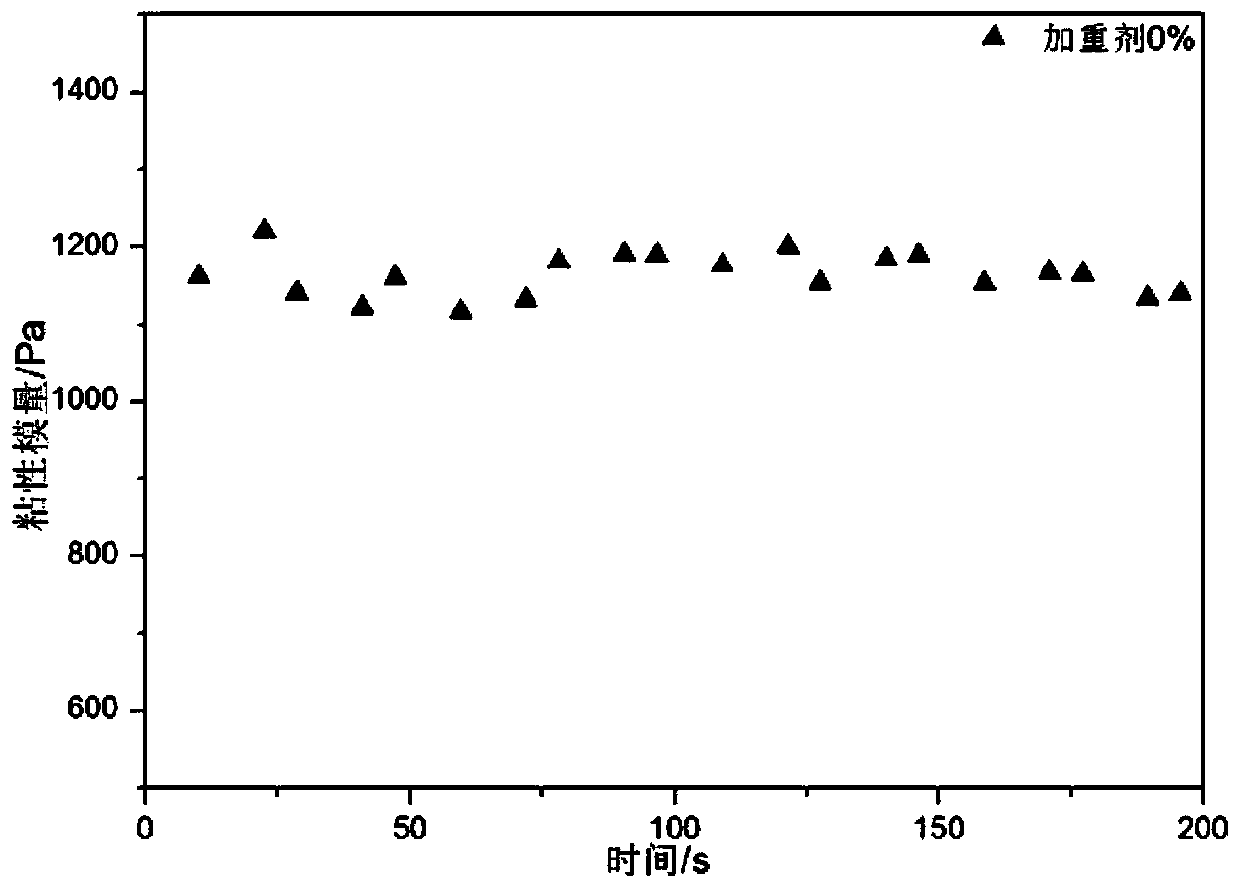

Embodiment 1

[0070] In this example, the compound gel well-killing rubber plug with high-temperature rapid gelation and aggravation is composed of the following components in mass percentage: barite powder 0.5%; toughening agent nano-silica 5%; polyacrylamide KYPAM 2%, molecular weight 800×10 4 g / mol; cross-linking agent polyethyleneimine 1.0%, thiourea 0.02%, the rest is water.

[0071]This embodiment also protects the preparation method of the composite gel kill plug with high-temperature rapid gelation and aggravation. The specific implementation steps are: first disperse the barite powder of the formula amount in water and stir at room temperature, and wait for the barite powder After fully dispersed, add the formula amount of toughening agent nano-silica to it, after the nano-silica is uniformly dispersed, add the formula amount of the main agent (polyacrylamide KYPAM particles), continue to stir for about 1 to 2 hours until the toughening agent Evenly distribute in the polymer solut...

Embodiment 2

[0076] In this example, the compound gel well-killing rubber plug with high-temperature rapid gelation and aggravation is composed of the following components in mass percentage: barite powder 10%; molecular weight: 233.39g / mol, initial viscosity (97560mPa·s); toughening Agent (sodium montmorillonite) 5%; main agent (acrylamide / 2-acrylamide-2-methylpropanesulfonic acid binary copolymer) 2%, molecular weight 800×10 4 g / mol; cross-linking agent (polyvinylamine) 1.0%, thiourea 0.02%, and the rest is clear water.

[0077] This embodiment also protects the preparation method of the composite gel kill plug with high-temperature rapid gelation and aggravation. The specific implementation steps are: first disperse the barite powder of the formula amount in water and stir at room temperature, and wait for the barite powder After fully dispersed, add the toughening agent (sodium-based montmorillonite) of the formulated amount to it, and add the main agent (acrylamide / 2-acrylamido-2-meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com