Cleaning agent for petroleum machinery equipment and preparation method thereof

A kind of technology of petroleum machinery and cleaning agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

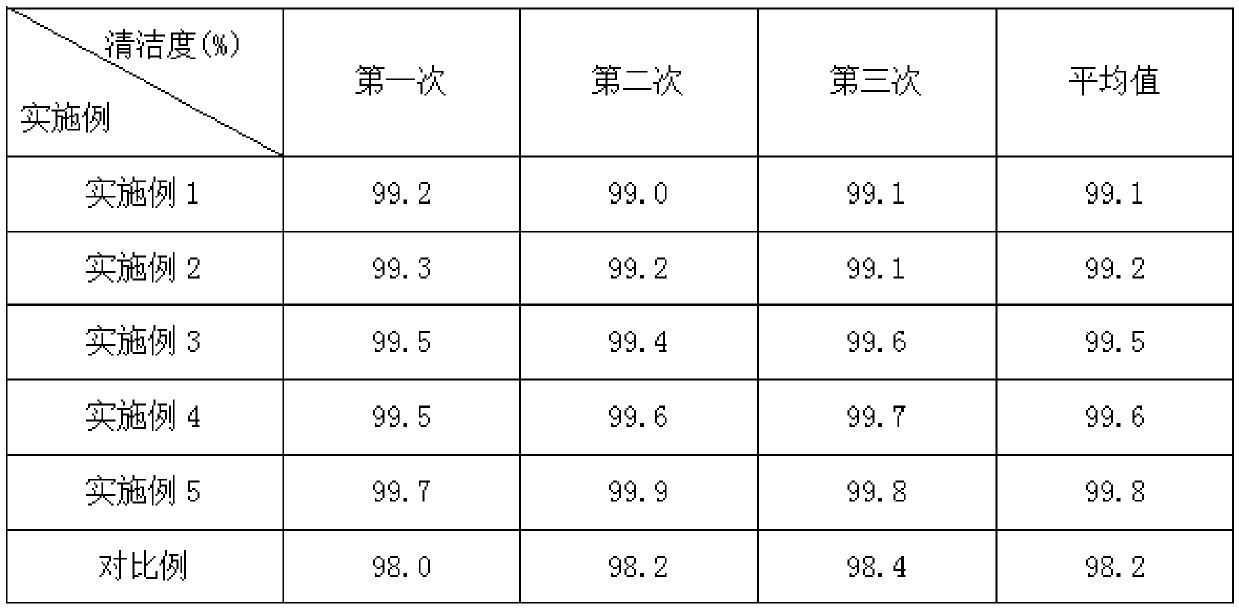

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a cleaning agent for petroleum machinery and equipment is composed of the following raw materials in parts by weight: 15 parts of Sapindus fruit peel extract, 13 parts of polyepoxysuccinic acid, 805 parts of polysorbate, 3 parts of nonylphenol polyoxyethylene ether. During the preparation, the sapindilla fruit peel is collected, washed and put into an ultrafine pulverizer for pulverization, and passed through a 300-mesh sieve after pulverization to obtain a sapindus powder; add ethanol with 5 times its mass to the sapindella powder, and then Ultrasonic treatment, ultrasonic treatment conditions: ultrasonic frequency 100kHz, ultrasonic treatment power 150W, ultrasonic treatment time 30min; filter after the first ultrasonic treatment to obtain the first filtrate and filter residue, add 5-10% filter residue quality to the filter residue double the amount of ethanol, then ultrasonic treatment, after filtration, the second filtrate...

Embodiment 2

[0019] In the embodiment of the present invention, a cleaning agent for petroleum machinery and equipment is composed of the following raw materials in parts by weight: 40 parts of Sapindus fruit peel extract, 28 parts of polyepoxysuccinic acid, 15 parts of polysorbate-8015 parts, 8 parts of nonylphenol polyoxyethylene ether. During the preparation, the sapindilla fruit peel is collected, washed and put into a superfine pulverizer for pulverization, and passed through a 300-mesh sieve after pulverization to obtain a sapindus powder; add ethanol with 10 times its mass to the sapindella powder, and then Ultrasonic treatment, ultrasonic treatment conditions: ultrasonic frequency 150kHz, ultrasonic treatment power 180W, ultrasonic treatment time 50min; filter after the first ultrasonic treatment to obtain the first filtrate and filter residue, add 10 times the weight of the filter residue to the filter residue Ethanol, and ultrasonic treatment, after filtration, the second filtrat...

Embodiment 3

[0021] In the embodiment of the present invention, a cleaning agent for petroleum machinery and equipment is composed of the following raw materials in parts by weight: 25 parts of Sapindus fruit peel extract, 18 parts of polyepoxysuccinic acid, 808 parts of polysorbate, 4 parts of nonylphenol polyoxyethylene ether. During preparation, collect Sapindus pericarp, wash it and put it into an ultrafine pulverizer for pulverization, pass through a 300-mesh sieve after pulverization, and obtain Sapindus powder; add ethanol with 6 times its mass to Sapindus powder, and then Carry out ultrasonic treatment, the condition of ultrasonic treatment: ultrasonic frequency 110kHz, ultrasonic treatment power is 160W, ultrasonic treatment time is 35min; Filtrate after the first ultrasonic treatment, obtain filtrate and filter residue for the first time, add 6 times of filter residue quality to filter residue Ethanol, then ultrasonic treatment, after filtration to obtain the second filtrate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com