A preparation method of high-strength aluminum alloy wire for energy-saving wires

An aluminum alloy wire, high-strength technology, applied in the direction of metal/alloy conductors, conductors, conductive materials, etc., can solve the problems that the electrical conductivity cannot meet the requirements and the strength cannot meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

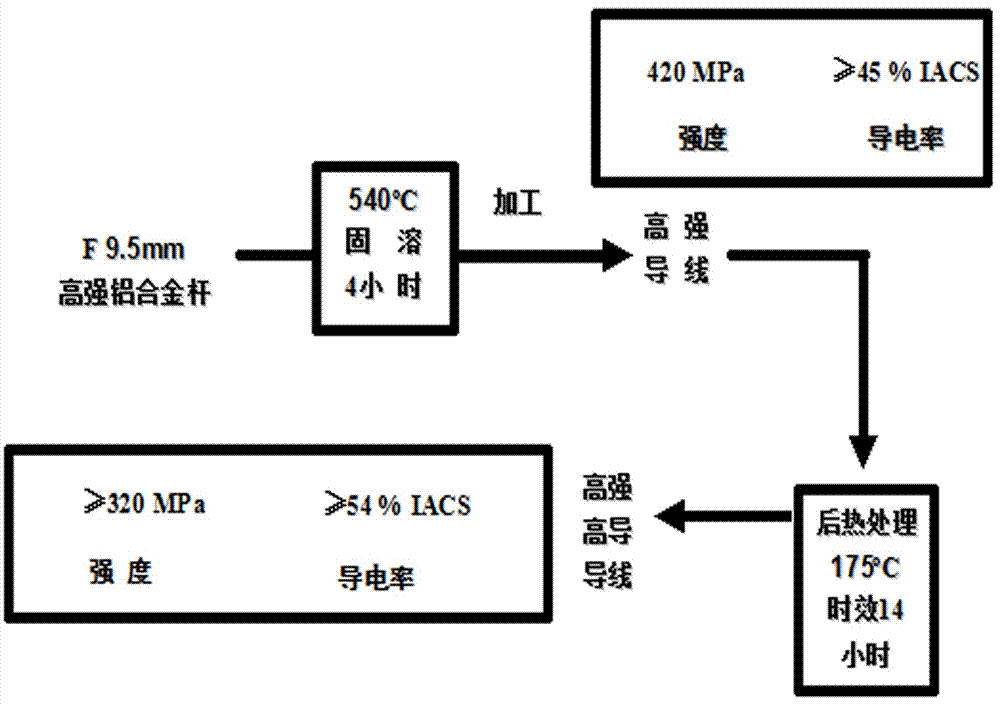

[0094] The preparation method of the present invention specifically comprises the following process steps:

[0095] (1) Heat treatment process of high-strength aluminum rod:

[0096] That is, pre-solution treatment. First, a hot-rolled aluminum rod with a diameter of 9.5 (±0.1) mm is selected, and its composition range is: Si: 0.57-0.74%; Fe: 0.2-0.3%; Cu: 0.01-0.03%; Mg: 0.63-0.7%; Zn: ≦0.05%; Ti:≦0.015%; the micro-Vickers hardness range of the aluminum rod is 60-70HV.

[0097] Secondly, randomly take radial sections at 3 places on the original aluminum rod as samples, and the Brinell hardness range: HBS: 100-200.

[0098] Finally, heat treatment is performed on the original aluminum rod: the temperature is 530°C-540°C, the high-strength aluminum alloy wire enters the heat treatment furnace for 5 minutes to start timing, and the holding time is 3.8 hours to 4.2 hours. The sample taken out is not allowed to stay in the air and must be quickly immersed in water for quenching ...

Embodiment 1

[0122] A method for preparing high-strength aluminum alloy wire for energy-saving wires, specifically comprising the following process steps:

[0123] (1) Heat treatment process of high-strength aluminum rod:

[0124] That is, pre-solution treatment. First, a hot-rolled aluminum rod with a diameter of 9.5 mm is selected, and its composition range is: Si: 0.64%; Fe: 0.25%; Cu: 0.02%; Mg: 0.68%; Zn: 0.02%; Ti: 0.015%.

[0125] Secondly, randomly take three radial sections on the original aluminum rod as samples, and the micro-Vickers hardness range: 60HV.

[0126] Finally, heat treatment is performed on the original aluminum rod: the temperature is 540°C, the high-strength aluminum alloy wire enters the heat treatment furnace for 5 minutes and the timing starts, and the holding time is 4 hours. .

[0127] (2) High-strength aluminum wire drawing process:

[0128] That is, cold drawing process. The production of high-strength aluminum wire with a diameter of 3mm has been draw...

Embodiment 2

[0148] A method for preparing high-strength aluminum alloy wire for energy-saving wires, specifically comprising the following process steps:

[0149] (1) Heat treatment process of high-strength aluminum rod:

[0150] That is, pre-solution treatment. First, a hot-rolled aluminum rod with a diameter of 9.6mm is selected, and its composition range is: Si: 0.57%; Fe: 0.2%; Cu: 0.01%; Mg: 0.63%; the micro-Vickers hardness range of the aluminum rod is 65HV.

[0151] Secondly, randomly take radial sections at 3 places on the original aluminum rod as samples, and the Brinell hardness range: HBS: 150.

[0152] Finally, heat treatment is performed on the original aluminum rod: the temperature is 530°C, the high-strength aluminum alloy wire enters the heat treatment furnace for 5 minutes to start timing, and the holding time is 3.8 hours. The sample taken out is not allowed to stay in the air, and it must be quickly immersed in water for quenching. .

[0153] (2) High-strength alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com