Device for vapor deposition of films

A vapor deposition and thin film technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of inability to guarantee temperature uniformity, unfavorable deposition of thin films, thermal deformation, etc., and achieve good temperature uniformity , The effect of ensuring uniformity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

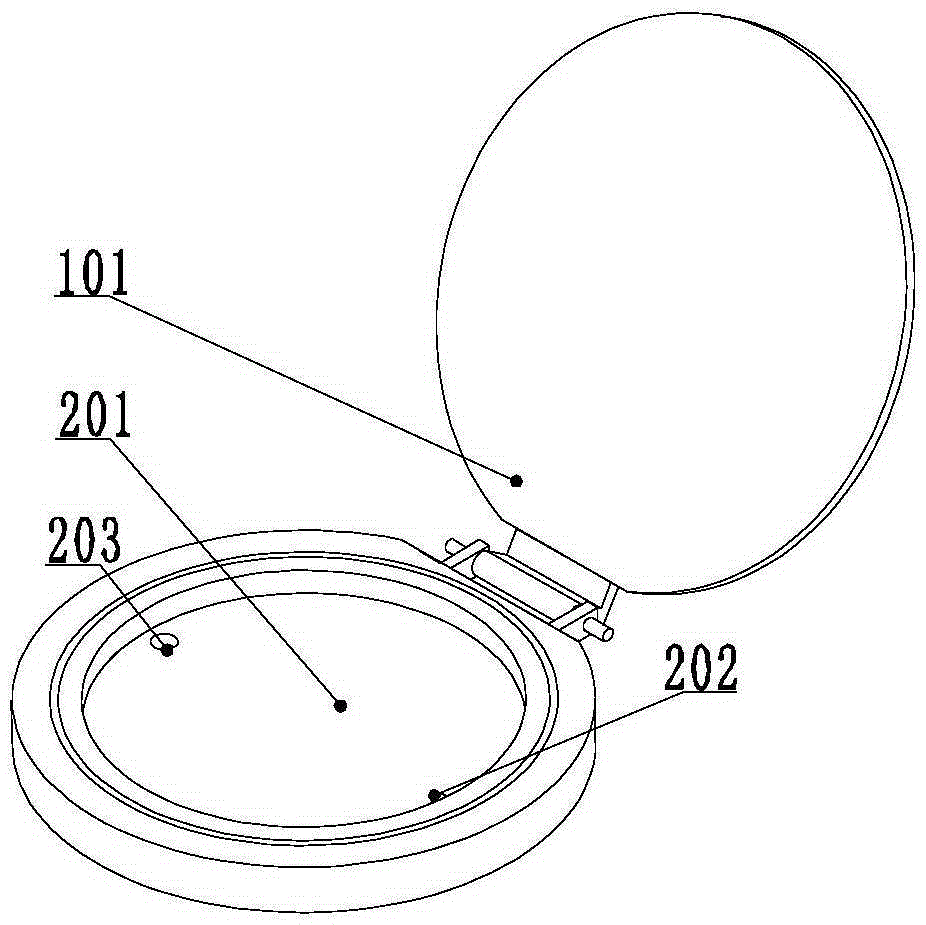

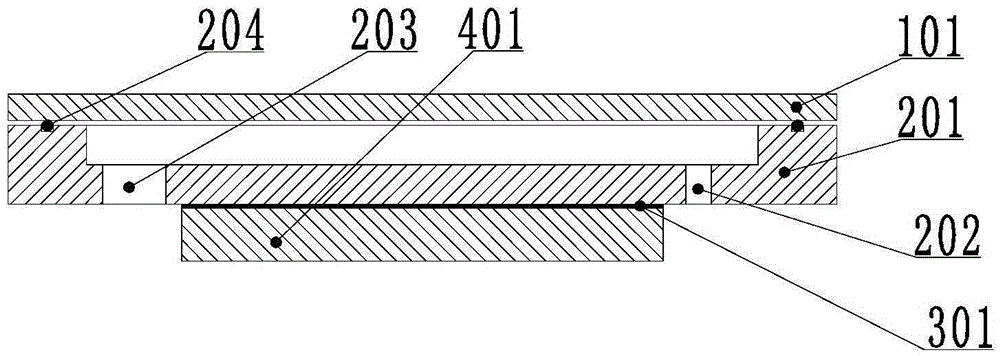

[0035] In actual use of the equipment, the heating temperature usually reaches 200°C. After a period of heating, the inner surface of the cavity warps, and the central area of the disc is 2-3mm higher than the surrounding area. When the silicon wafer is put into the cavity, the silicon wafer cannot be well bonded to the inner surface of the cavity, and the contact only occurs in a local area. Due to the warpage of the inner surface of the cavity, the temperature distribution on the silicon wafer is inconsistent, which also leads to the inconsistent deposition of thin films on the silicon wafer. In order to ensure uniform deposition on the silicon wafer, the design of the cavity is improved by adding a ring groove to avoid warping and deformation of the cavity.

[0036] The effect of this anti-deformation groove can be verified by simulation. It can be seen from the temperature simulation that after adding the annular groove, the temperature on the inner surface of the cavit...

Embodiment 2

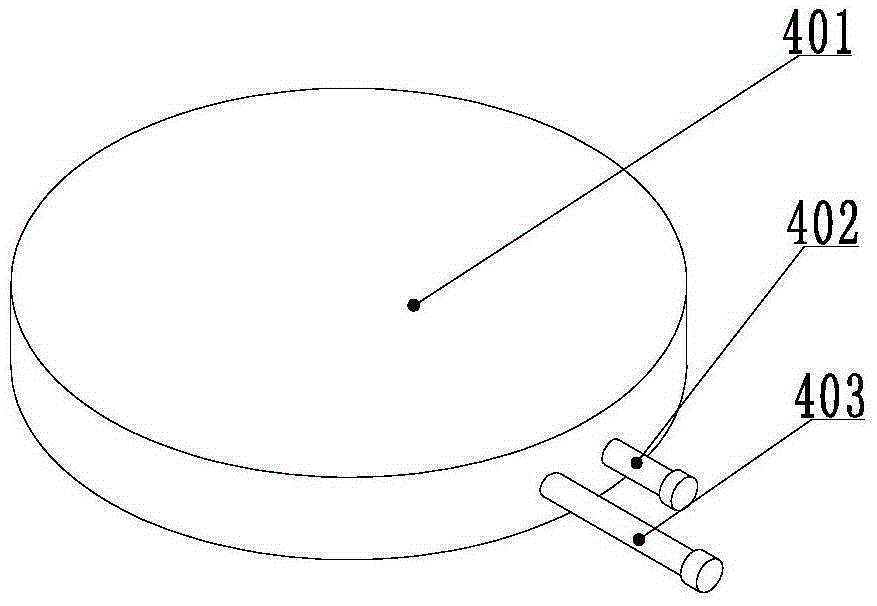

[0038] Apply the vapor phase film deposition device provided by the present invention to deposit an ALD aluminum oxide film with a thickness of 20 nm on the surface of a silicon wafer.

[0039] Two kinds of reactants are used in the embodiment, the reactant A is trimethylaluminum, and the reactant B is water. Nitrogen is used as the carrier gas of the reactants, and the flow rate of the carrier gas is 100 sccm.

[0040] The reaction temperature was set at 180°C, and a 4-inch silicon wafer was used as the substrate for the reaction. Put the cleaned silicon wafer into the chamber and vacuumize the chamber. When the pressure in the cavity is pumped below 10Pa, start heating, and the temperature of the cavity will rise rapidly. When the temperature in the cavity is stabilized at 180±3°C, open the valve of the reactant A trimethylaluminum for 1 second, at this time the reactant A trimethylaluminum enters the cavity in the form of pulses. After the reactant A, trimethylaluminum, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com