Method for detection of bridge hinge joint condition through FWD (Falling Weight Deflectometer)

A technology of hinge and condition, applied in the field of bridge hinge condition detection using FWD, can solve the problems of high load test cost, long-term traffic closure, etc., and achieve the effect of high accuracy, small impact, accurate and effective measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation method of the present invention will be further described below in conjunction with the examples. This embodiment is used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

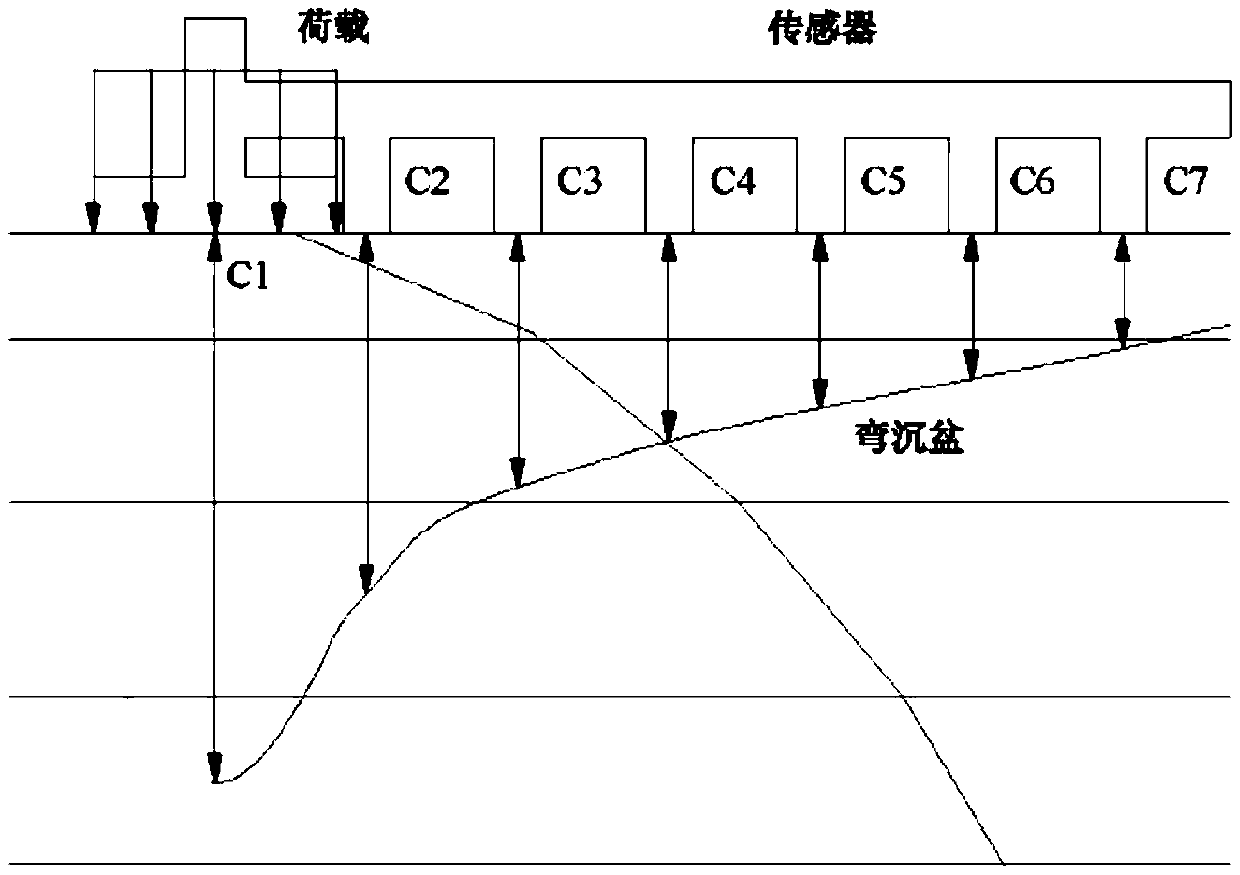

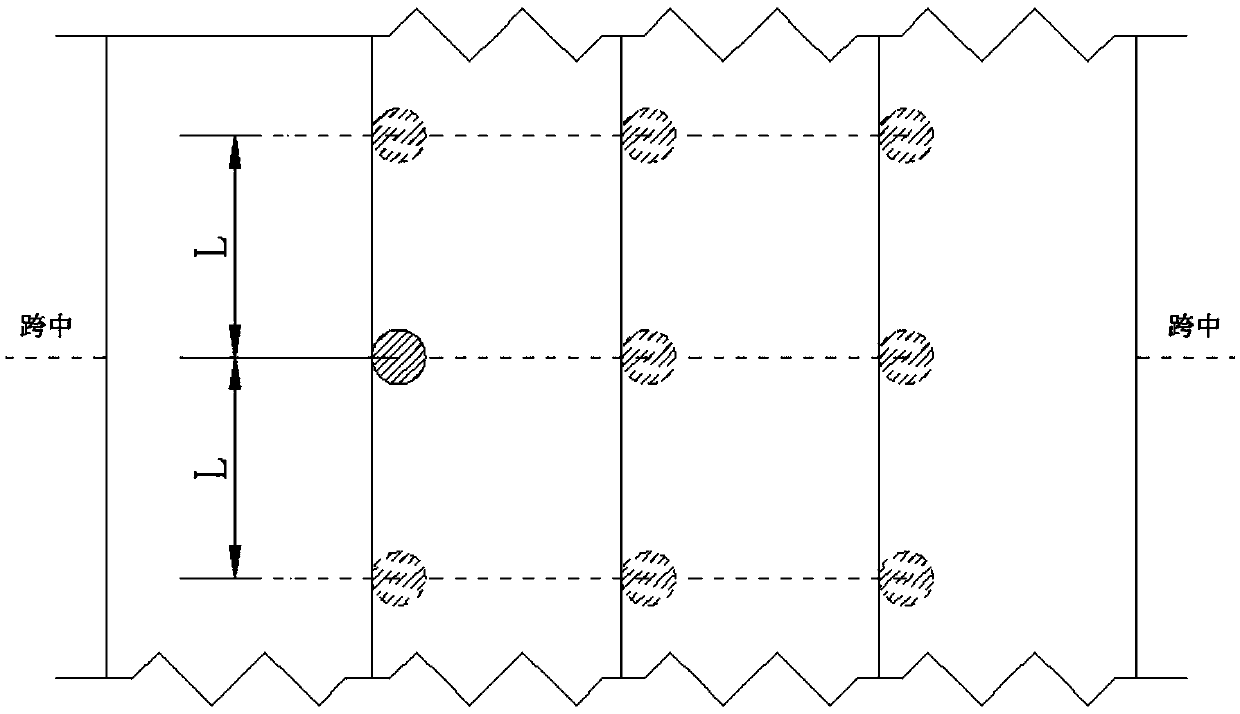

[0039] The detection scheme adopted in this embodiment is to detect each hinge joint on the cross-section in the middle of the span first, and then select the next section at intervals in the direction of the bridge head in the longitudinal direction.

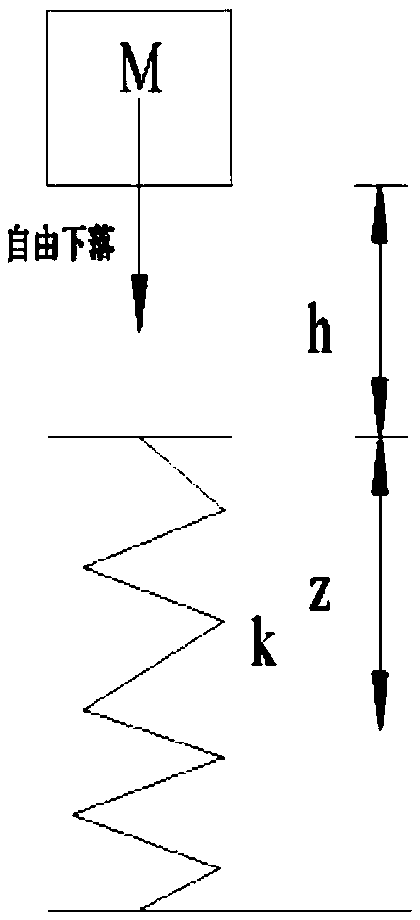

[0040] see image 3 and Figure 4 , when the traffic on the bridge to be inspected is easy to close, the FWD inspection vehicle can be used to detect the transverse hinge capacity of the hinge joint in the direction perpendicular to the hinge joint. "Design Code" (JTGD40-2002) evaluates the load transfer capacity of hinged joints:

[0041] .

[0042] In the formula: is the load transfer capacity coefficient of hinge joint;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com