Flexible circuit board manufacturing process automatic monitoring and intelligent analysis system and method

A flexible circuit board and manufacturing process technology, applied in the field of automatic monitoring and intelligent analysis system of flexible circuit board manufacturing process, can solve the problems of high false alarm rate, high image density, long manual detection time, etc., to reduce errors The effect of increasing the alarm rate, simplifying the detection process, and improving the ability of fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

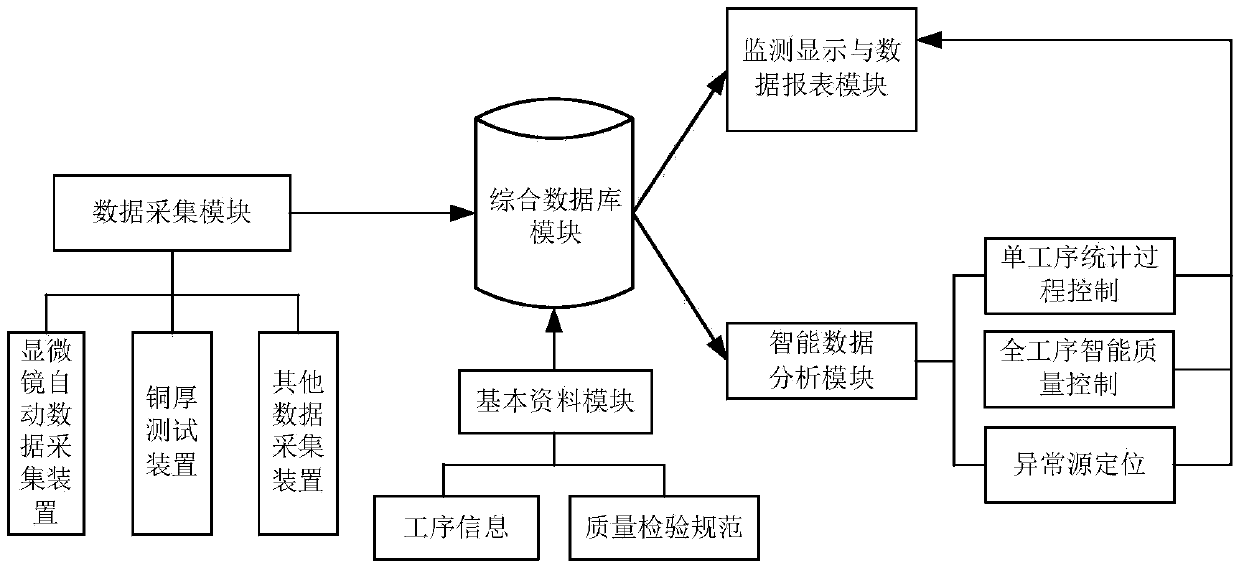

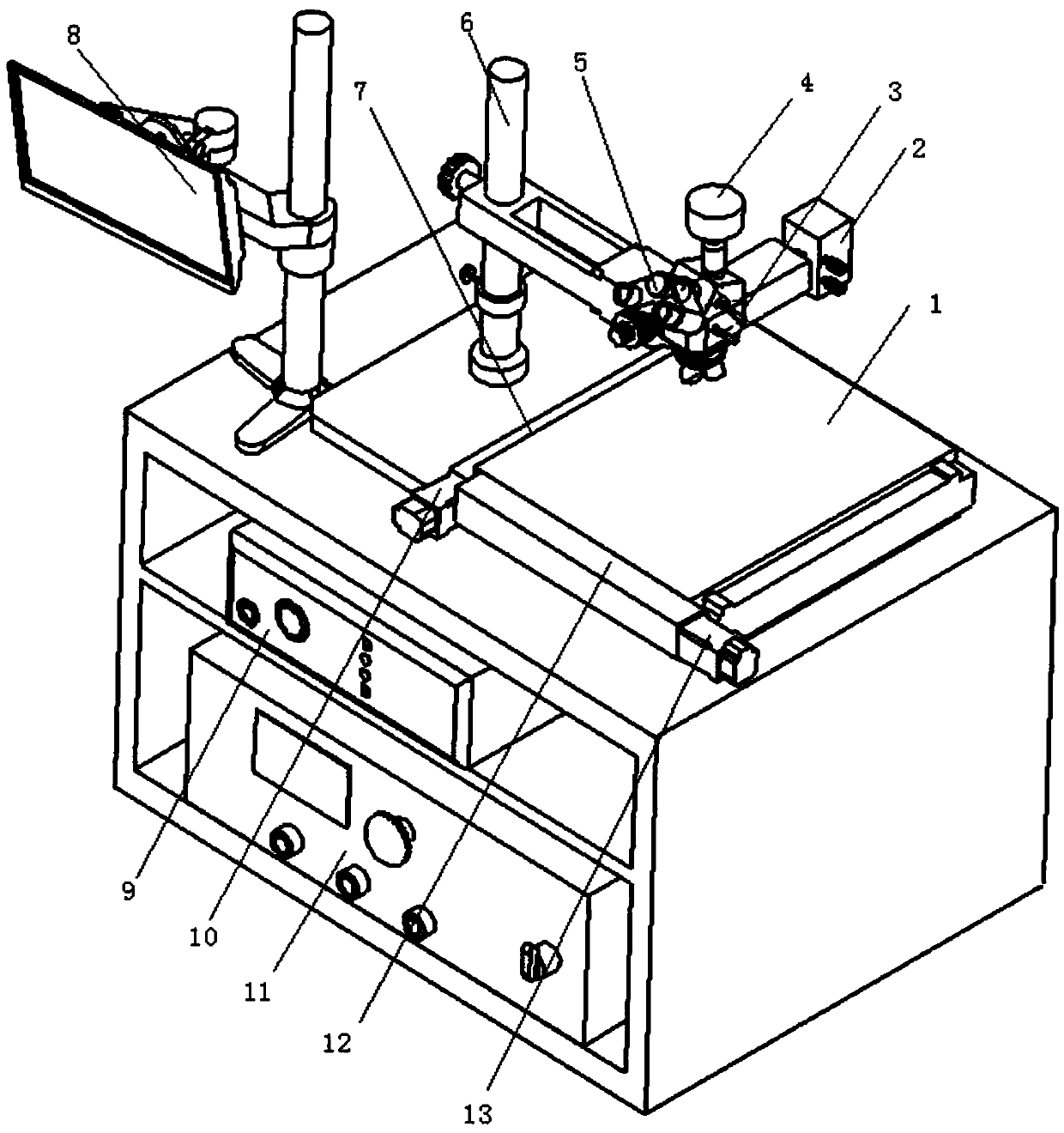

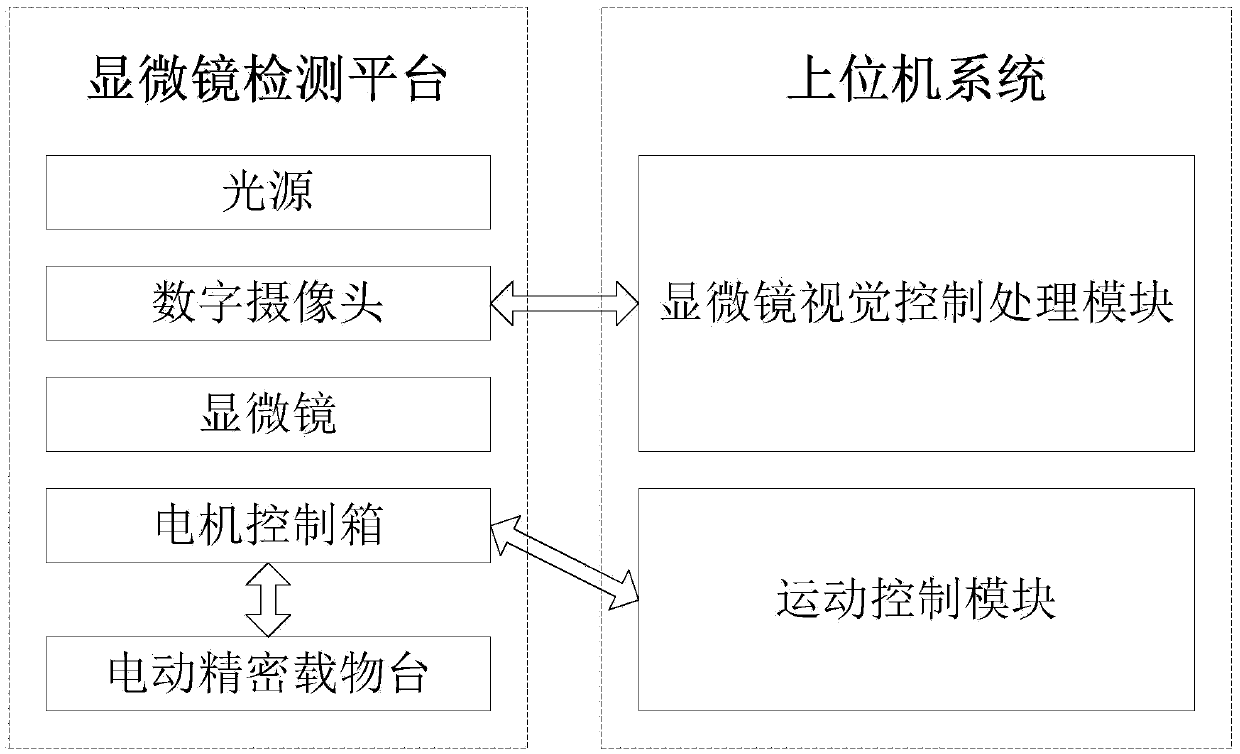

[0049] Such as figure 1 As shown, the automatic monitoring and intelligent analysis system of the flexible circuit board manufacturing process includes a basic data module, a data acquisition module, a comprehensive database module, an intelligent data analysis module, and a monitoring display and data reporting module. The data acquisition module includes microscope automatic data acquisition device, copper thickness testing device and other data acquisition devices, which are mainly used to collect key physical parameters of each process in the flexible circuit board manufacturing process and flexible circuit board quality data; the basic data module includes process information and quality inspection specifications, which are mainly used as standard information materials for judgment and inspection during the quality and defect inspection of each process of flexible circuit boards; the intelligent data analysis module includes statistical process control algorithms to identi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com