Silver-doped vanadium pentoxide nanowire, preparing method of silver-doped vanadium pentoxide nanowire and preparing method of electrochromic device

A vanadium pentoxide nano- and silver-doped technology is applied in the preparation of electrochromic devices, and its preparation, in the field of silver-doped vanadium pentoxide nanowires, can solve the problems of easy collapse of layered structures, poor electrical conductivity, Problems affecting electrochromic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention discloses a method for preparing silver-doped vanadium pentoxide nanowires, comprising the following steps:

[0034] Mix vanadium source, template agent, water, nitric acid and silver nitrate to obtain a mixture precursor;

[0035] The mixture precursor is subjected to hydrothermal reaction to obtain silver-doped vanadium pentoxide nanowires.

[0036] This application improves the conductivity and layer spacing of vanadium pentoxide by doping silver in layered vanadium pentoxide, and prepares silver-doped vanadium pentoxide nanowires with high aspect ratio, which improves the electrical conductivity of the material. Chromogenic properties.

[0037] According to the present invention, vanadium source, template agent, water, nitric acid and silver nitrate are firstly mixed to obtain a mixture precursor. In order to mix the raw materials uniformly and prevent the raw materials from reacting prematurely, the preparation of the mixtu...

Embodiment 1

[0056] Dissolve 0.3g of ammonium metavanadate and 0.5g of P123 in 30ml of distilled water, add 2ml of 1mol / L nitric acid, stir at room temperature for 7h, add 0.1g of silver nitrate to the above solution, and continue stirring for 1h. Transfer the obtained precursor solution to a 50ml crystallization kettle, and conduct a hydrothermal reaction at 120°C for 24 hours. After the crystallization kettle is naturally cooled to room temperature, the product is taken out, filtered and washed with distilled water and ethanol. Repeat three times until P123 is completely washed. Finally, the washed product was dried overnight at 80°C to obtain silver-doped vanadium pentoxide nanowires.

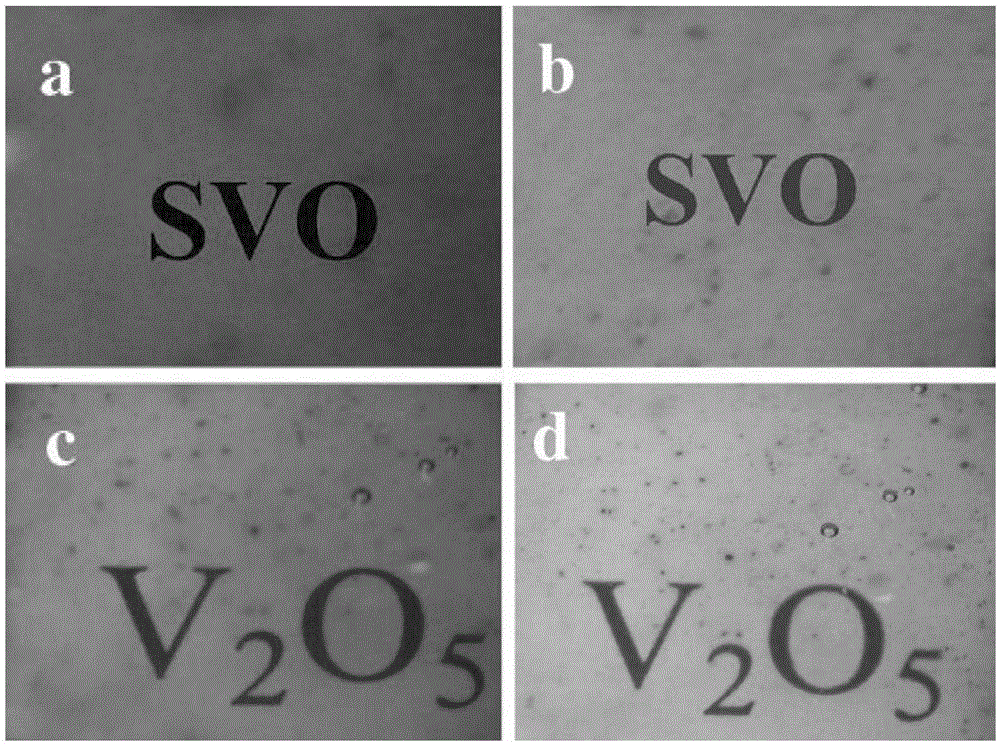

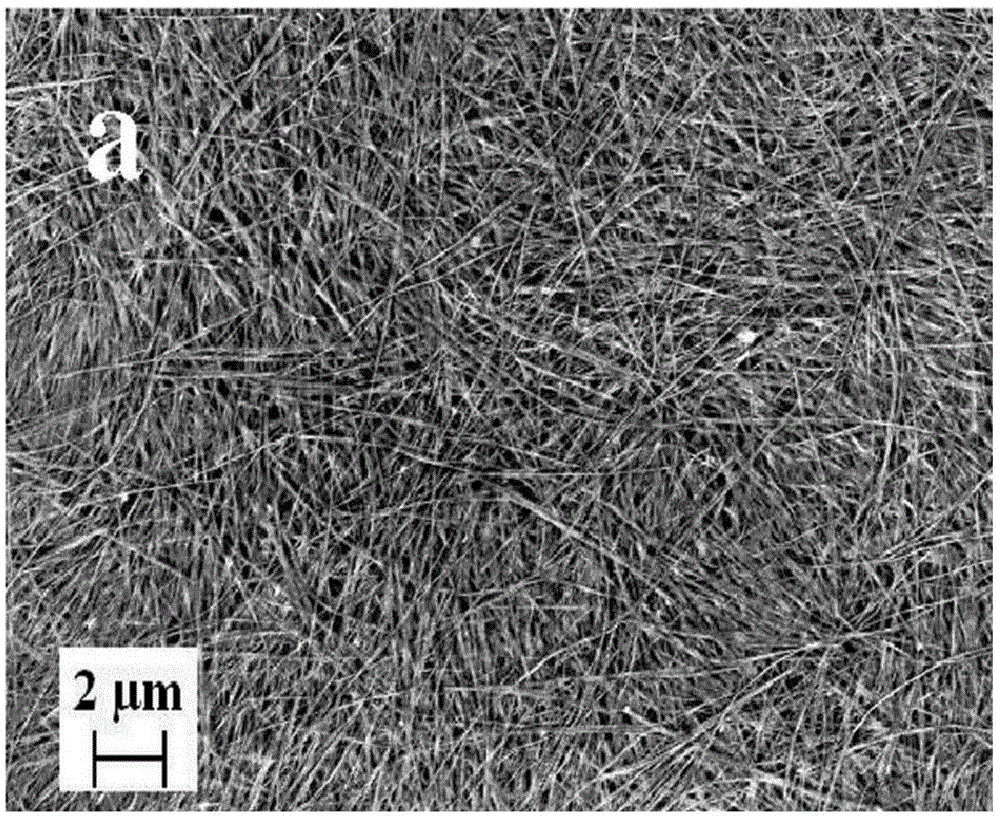

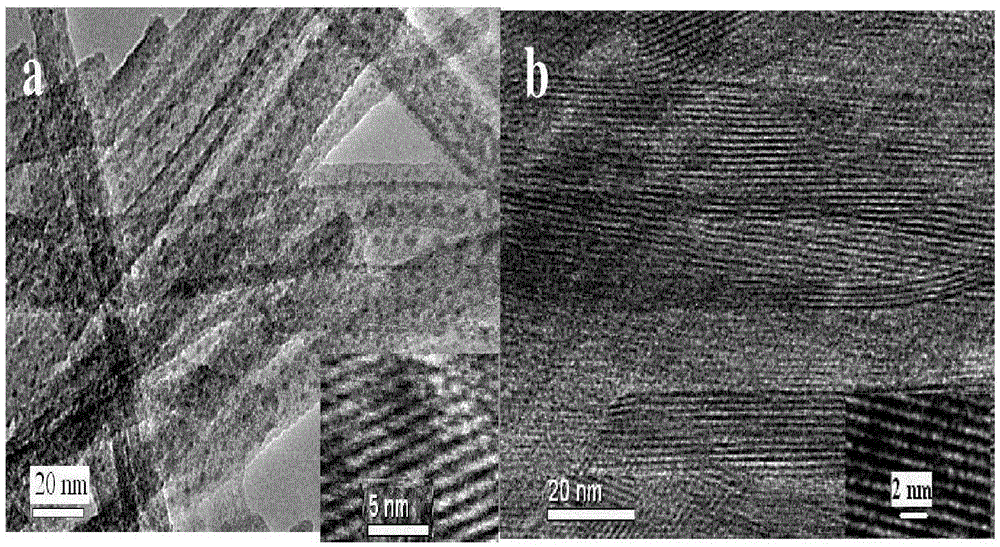

[0057] figure 1 The SEM photo of the silver-doped vanadium pentoxide nanowires prepared in this embodiment, figure 2 The TEM images of the silver-doped vanadium pentoxide nanowires and the silver-doped vanadium pentoxide nanowires prepared in Example 1, the lower right embedded image is its HRTEM image...

Embodiment 2

[0060] According to the scheme of Example 1, 0.3g of ammonium metavanadate and 0.5g of P123 were dissolved in 30ml of distilled water, 2ml of 1mol / L nitric acid was added, stirred at room temperature for 7h, 0.2g of silver nitrate was added to the above solution, and stirred for 1h; the obtained The precursor solution was transferred to a 50ml crystallization kettle, and hydrothermally reacted at 120°C for 24 hours. After the crystallization kettle was naturally cooled to room temperature, the product was taken out, filtered and washed with distilled water and ethanol. Repeated three times until P123 was completely washed, and finally washed The product was dried overnight at 80 °C to obtain silver-doped vanadium pentoxide nanowires.

[0061] 0.25 g of silver-doped vanadium pentoxide nanowires prepared by the above scheme were dispersed in 20 ml of ethanol, stirred vigorously at room temperature until the solution volume was concentrated to 5 ml, and the resulting suspension wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com