Block-based switched reluctance motor with short end part and short magnetic circuit and control circuit thereof

A technology of switched reluctance motor and control circuit, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, magnetic circuit rotating parts, etc. The problems such as the length of the pass loop can achieve the effects of small torque ripple, low control cost, and increased air gap magnetic field width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

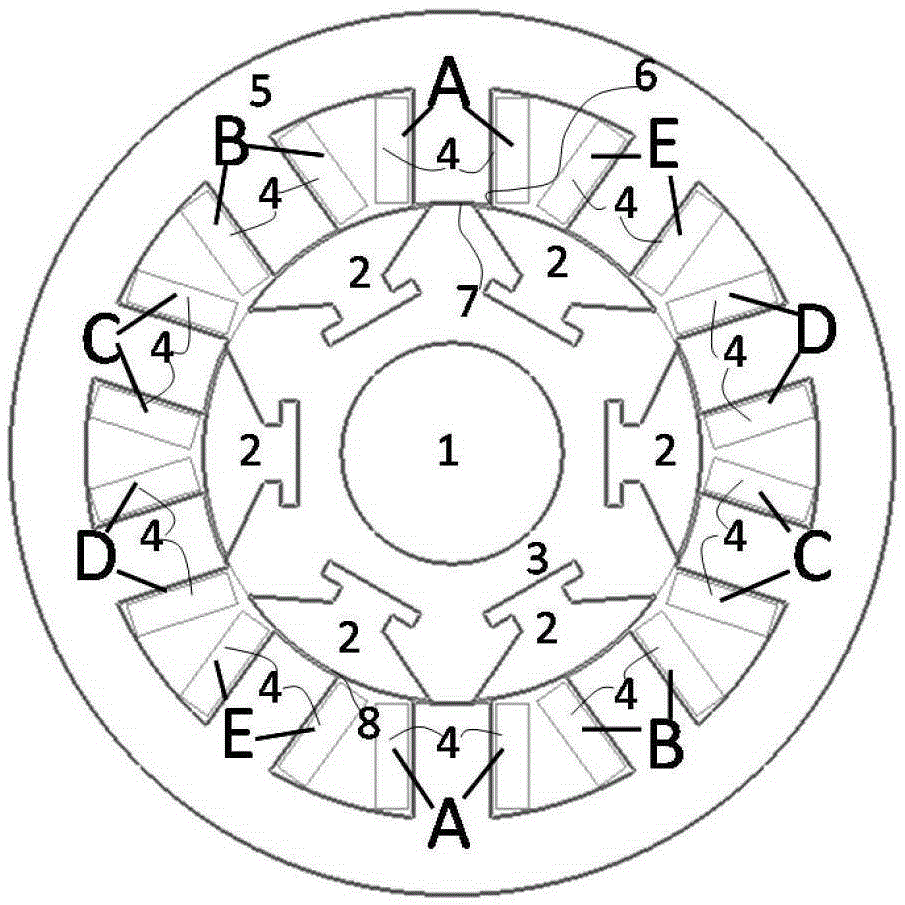

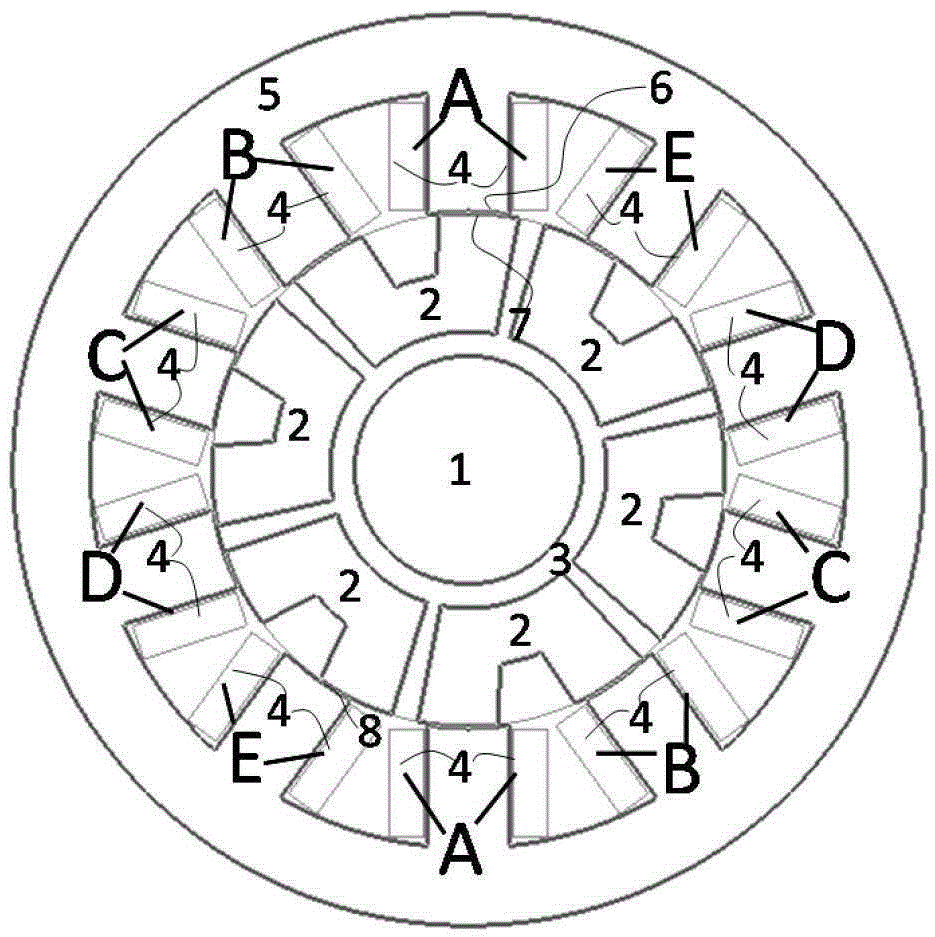

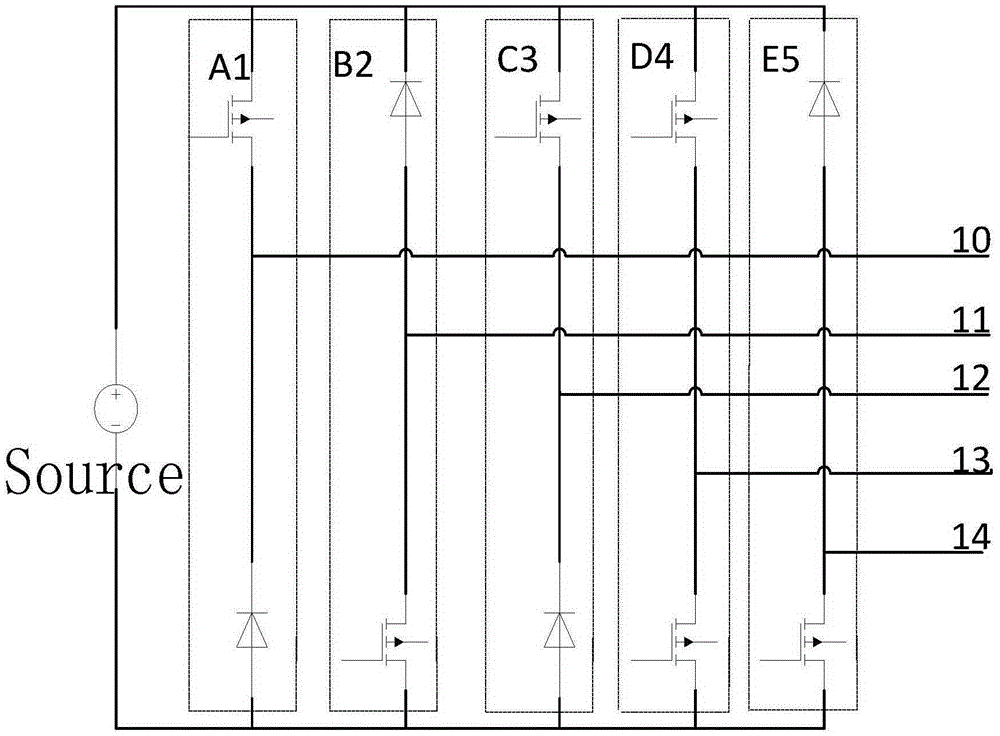

[0044] The segmented switched reluctance motor with short end and short magnetic circuit is a multi-phase motor. The number of stator poles of the motor is even, the number of motor phases is M, and the number of motor stator poles is N. The relationship between the number of motor phases and the number of stator poles is : N=K×M; K=2, 3, 4, 5, 6.... The number of motor phases M≥5 and is an odd number. The number of rotor block-type magnetic materials is the number of rotor poles A control main circuit of short-end short magnetic circuit block type switched reluctance motor includes several bridge arms, the bridge arms are composed of two controllable switching devices or diode devices connected in series, and the bridge arms are directly connected to the power bus Or on the DC bus, the relationship between the number W of bridge arms of the motor con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com