Water-in-oil type purple sweet potato pigment micro-emulsion and preparation method thereof

A purple sweet potato pigment, water-in-oil technology, applied in the field of microemulsion, can solve the problems of limited use, little research, difficult to adjust the interface radius and fluidity, etc., and achieve the effect of cost saving, bright and stable color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

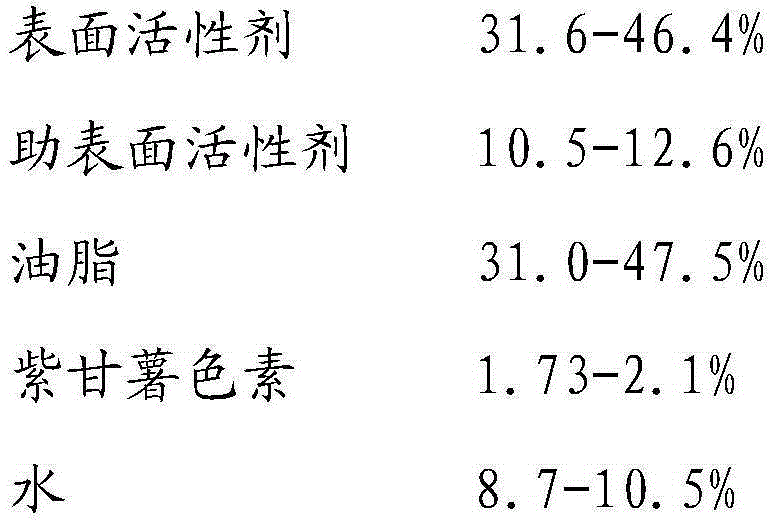

[0028] (1): raw materials:

[0029] (2): Preparation method:

[0030] 1) The purple sweet potato pigment solid powder in the raw material ratio is mixed with water to form a purple sweet potato pigment aqueous solution, and then a co-surfactant is added to form the water phase in the microemulsion system.

[0031] 2) The oil phase in the microemulsion liquid is formed after the oil is mixed with the surfactant.

[0032] 3) Add the aqueous phase mixture formed in step 1) dropwise at a speed of 300r / min to the oil phase in the microemulsion system formed in step 2), and stir evenly.

[0033] The appearance of the microemulsion prepared by the present invention is clear and transparent, and the content of purple sweet potato pigment is high. Further, the stability analysis of the microemulsion product of this embodiment is carried out, and the microemulsion is placed in a 28°C incubator for 28 days. Delamination and particle aggregation appear, and the stability is good.

Embodiment 2

[0035] (1): raw materials:

[0036] (2): The preparation method is the same as in Example 1.

[0037] The appearance of the microemulsion prepared by the present invention is clear and transparent, and the content of purple sweet potato pigment is high. Further, the stability analysis of the microemulsion product of this embodiment is carried out, and the microemulsion is placed in a 28°C incubator for 28 days. Delamination and particle aggregation appear, and the stability is good.

Embodiment 3

[0039] (1): raw materials:

[0040] (2): The preparation method is the same as in Example 1.

[0041] The appearance of the microemulsion prepared by the present invention is clear and transparent, and the content of purple sweet potato pigment is high. Further, the stability analysis of the microemulsion product of this embodiment is carried out, and the microemulsion is placed in a 28°C incubator for 28 days. Delamination and particle aggregation appear, and the stability is good.

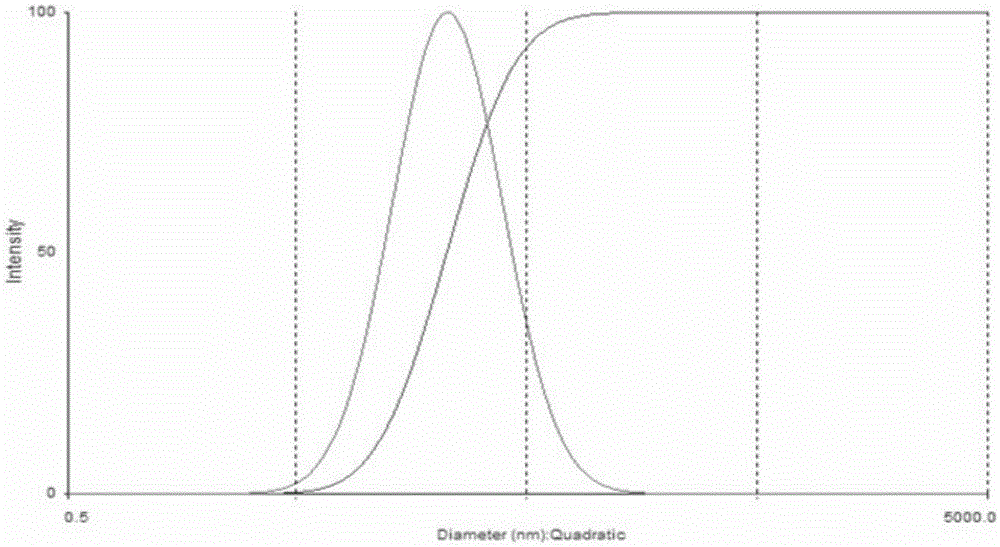

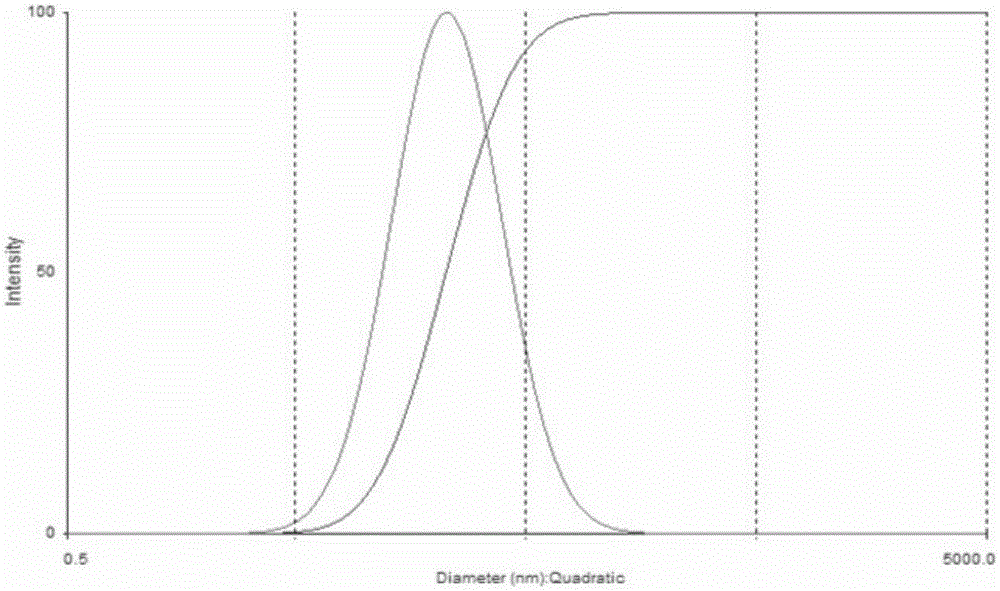

[0042] At the same time, the microemulsion was diluted 300 times by volume with absolute ethanol and filtered through a 220nm organic membrane, and the particle size value of the microemulsion was measured by laser light scattering. The particle size of the microemulsion system is 31.2nm, less than 100nm, and its particle size distribution is as follows: figure 1 shown. The particle distribution of the microemulsion system is concentrated, which meets the requirements of the microemulsion. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com