Green manufacturing method and system of spectacle lenses

A technology of green manufacturing and spectacle lenses, applied to other home appliances, optical components, home appliances, etc., can solve environmental pollution and other problems, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

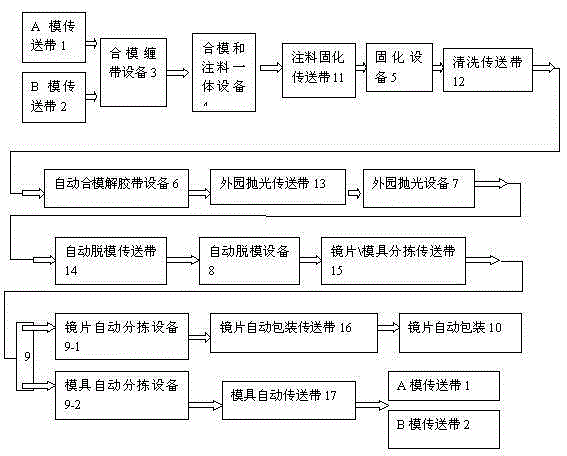

[0022] like figure 1 shown.

[0023] A green manufacturing method for spectacle lenses. First, the entire manufacturing process is completed in an ultra-clean workshop, that is to say, the figure 1 The entire production line shown is all placed in the ultra-quiet workshop with a purification level above 1000PPM. At the same time, suction equipment is installed outside the workshop to extract the dust generated during the production process out of the clean workshop, and then the corresponding dust treatment is installed outside the workshop. The equipment is enough. Secondly, the two A-modes and B-modes sent from the A-mode conveyor belt and the B-mode conveyor chain for curing are wound with super-light tape to form an injection mold with an injection cavity. The super-light used The optical tape requires a natural separation interface between the tape and the cured material to facilitate separation. Send the injection mold wrapped with the tape into the injection equipment ...

Embodiment 2

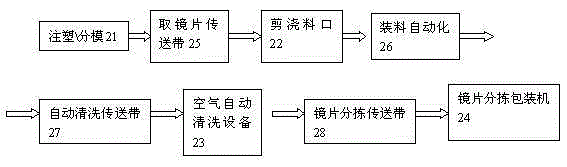

[0025] like figure 2 shown.

[0026] A kind of green manufacturing method of spectacle lens, at first using figure 2 The entire production line shown is installed in the ultra-clean workshop, so that the entire production process can be completed in the ultra-clean workshop (above 1000PPM level), and secondly, the lens after injection molded by the injection molded parting equipment is injected into the pouring material. The mouth cutting equipment performs the operation of cutting the pouring mouth. After the cutting is completed, the lens is sent to the automatic air cleaning conveyor belt by the automatic air cleaning equipment to be blown with clean air. After the blown lens is sent to the sorting equipment through the conveyor belt Sorting, and finally automatic packaging.

Embodiment 3

[0028] like figure 1 shown.

[0029]A green manufacturing system for spectacle lenses, which includes A-mode conveyor belt 1, B-mode conveyor belt 2, mold-closing tape wrapping equipment 3, material injection equipment 4, curing equipment 5, mold-closing and tape-removing equipment 6 installed in a clean workshop, Outer circle polishing equipment 7, automatic demoulding equipment 8, mold lens sorting equipment 9, lens automatic packaging equipment 10, the A mold and B mold used for mold closing are sent to the mold clamping belt through the A mold conveyor belt 1 and the B mold conveyor belt 2 The equipment 3 uses the ultra-light tape to wind in the circumferential direction to form an injection mold with a material injection cavity, and the injection mold is sent to the injection equipment 4 for injection, and the injected injection mold is sent to the injection curing conveyor belt 11 for curing The equipment 5 is solidified, and the cured injection mold is sent to the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com