Multi-effect evaporation and concentration device and technology thereof for solution containing sulfuric acid and salts thereof

A multi-effect evaporation and concentration device technology, applied in the direction of heating water/sewage treatment, water treatment parameter control, water/sludge/sewage treatment, etc., to achieve the effect of reducing production costs, reducing steam consumption, and reducing evaporation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

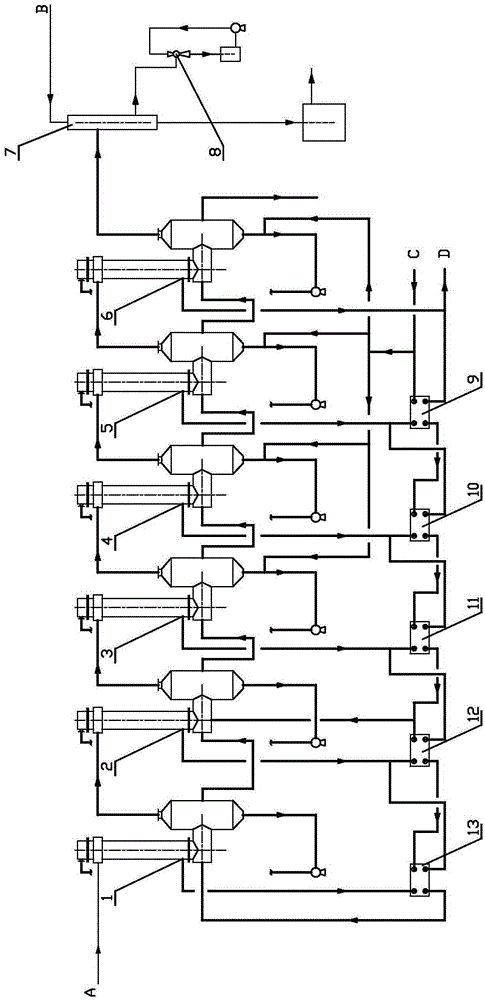

[0055] Such as figure 1 As shown, the six-effect evaporator is provided with a five-stage preheater 9 , a four-stage preheater 10 , a three-stage preheater 11 , a secondary preheater 12 and a primary preheater 13 .

[0056] The acid feeding process of the acid bath C is as follows: the acid bath C is divided into 6 branches, and flows into the first-effect evaporator 1, the second-effect evaporator 2, the third-effect evaporator 3, the four-effect evaporator 4, the five-effect evaporator 5, Six-effect evaporator 6: The acid bath C without preheating by the preheater is divided into four paths and enters the three-effect evaporator 3, the four-effect evaporator 4, the five-effect evaporator 5, and the six-effect evaporator 6; the rest of the acid bath C enters the fifth-stage preheater 9, and uses the condensed water discharged from the fourth-stage preheater 10 and the heated steam condensed water of the five-effect evaporator 5 as heat sources; then enters the fourth-stage pr...

Embodiment 2

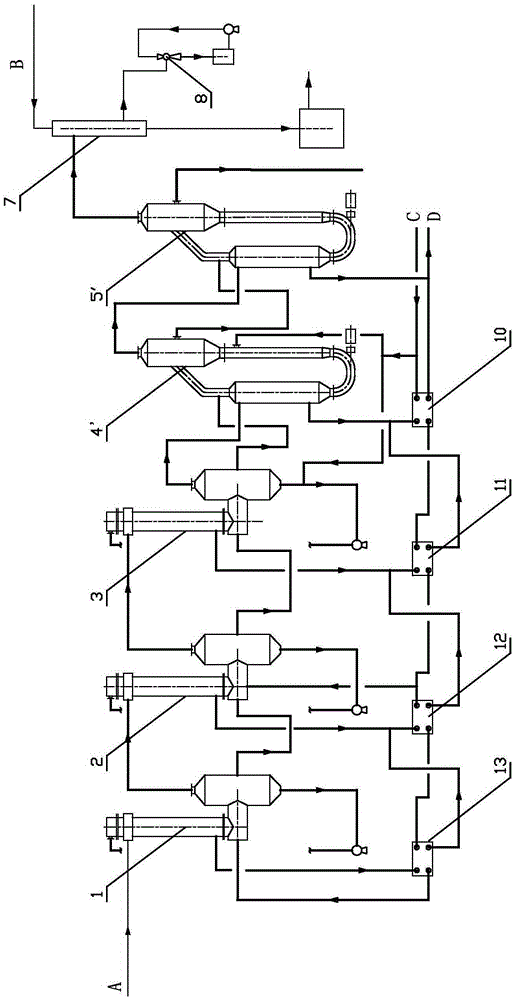

[0064] Such as figure 2 As shown, the acid bath five-effect evaporation crystallization is basically the same as the above-mentioned process of embodiment 1, and the flow process of a preheater is missing. The first three effects are evaporators, and the last two effects are four-effect evaporation crystallizer 4' and five-effect Evaporation crystallizer 5'.

[0065] The five-effect evaporating crystallizer 5' does not feed acid, which is for more evaporation and crystallization of sodium sulfate, and the four-effect evaporation crystallizer 4' may not feed or less acid, in order to adjust the amount of crystallization of sodium sulfate; the four-effect evaporation crystallization The 4' of the device is more acid, which can reduce the crystallization of Yuanmingfen. On the contrary, the output can be increased.

[0066] The steam-water ratio of the five-effect evaporation crystallization in the acid bath of the present invention reaches 0.237; the steam-water ratio reaches...

Embodiment 3

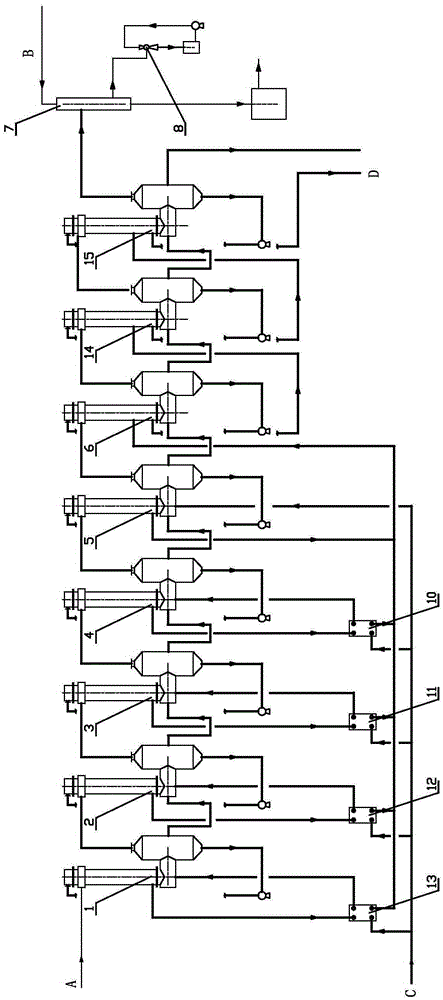

[0068] Such as image 3 As shown, the eight-effect evaporation of acidic water, the water intake process of acidic water or two-bath water is designed according to the characteristics of high water temperature and can reach the boiling point of water intake, and the acidic water enters the first five-effect evaporator through five branches: One-effect heating steam condensate water preheating first-effect evaporator 1 water inlet; second-effect heating steam condensate water preheating second-effect evaporator 2 water inlet; three-effect heating steam condensate water preheating three-effect evaporator 3 inlet water; four-effect Heating steam condensed water to preheat four-effect evaporator 4 inlet water; fifth-effect inlet water can reach boiling point inlet water without preheating; sixth-effect, seventh-effect, and eight-effect only accept the parallel flow drainage of the previous effect, not separate water inlet. The design of the water intake is based on the heat that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com