Modification method for saving operation cost of water treatment plant supplied with water from low turbidity water source

A technology of operating cost and water purification plant, which is applied in the field of upgrading and transformation of water purification plant, and can solve problems such as difficult treatment, high operating cost of treatment process, and low turbidity of water source water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

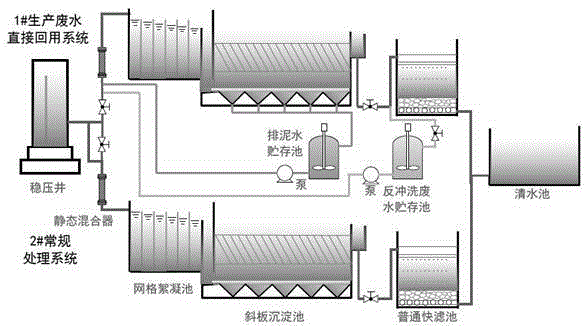

[0014] Specific implementation mode 1: This implementation mode provides a transformation method for low-turbidity water source water purification plant to save operating costs, and the method is realized by the following steps:

[0015] Step 1: Investigate the water quality and quantity changes of the water source water of the water purification plant in different seasons, and evaluate the treatment effect and operating cost of the existing process of the water purification plant;

[0016] Step 2: Under the conditions of low turbidity and low pollution in the source water of the water purification plant, implement measures such as upgrading, rebuilding, and optimizing operating parameters for each process link;

[0017] Step 3: Evaluate the benefits of the effluent water quality and economic costs of the water purification plant after the implementation of the transformation plan to achieve the goal of saving operating costs.

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is a further description of the method described in Embodiment 1.

[0019] The water quality change mentioned in step 1 specifically refers to: According to the collected long-term operation monitoring data of the water plant, the report is produced to obtain data such as water volume change, raw water and factory water quality, chemical consumption, power consumption, and water consumption. . Among them, the production report includes the water source water quality report, the water quality statistical report, the water plant power consumption report, the factory water quality report and the production report.

[0020] The change of water volume mentioned in step 1 refers to the daily average water supply volume and the 24h hourly water volume treated by the water plant in the past 2 years (since the start of the assessment, the range of data within 2 years is given).

[0021] The water quality of raw water mentioned in this embodiment sp...

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment is a further description of the method described in Embodiment 1.

[0023] The treatment effect of the existing process described in step 1 specifically refers to: the existing conventional process of the water purification plant mainly includes mixing, coagulation, sedimentation, filtration, disinfection, analysis of the removal rate of turbidity, organic matter and other indicators of each treatment unit and the final The control range of various water quality indicators in the factory water, and the water quality characteristics of the sludge discharge from the coagulation tank, the sludge discharge from the sedimentation tank and the backwash wastewater from the filter are analyzed.

[0024] The mixing described in this embodiment mainly includes mechanical mixing and hydraulic mixing. adopted by the factory.

[0025] Coagulation: a method of purifying wastewater by adding a coagulant to the treated water to separate the colloidal subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com